In short, Polytetrafluoroethylene (PTFE) lip seals are deployed in demanding applications where conventional elastomer seals would quickly fail. They excel in environments characterized by high rotational speeds, extreme temperatures, aggressive chemicals, and conditions where lubrication is minimal or absent.

The core reason for choosing a PTFE lip seal is its ability to solve sealing challenges under extreme operating conditions. They are not a universal replacement for standard seals but are a specialized solution for high-performance machinery where reliability is non-negotiable.

The Defining Characteristics of PTFE Seals

To understand where PTFE seals are used, one must first understand the fundamental properties that set them apart from traditional sealing materials. These characteristics directly dictate their ideal operating environments.

High-Speed Rotational Capability

PTFE has an exceptionally low coefficient of friction. This property allows PTFE lip seals to handle very high surface velocities, often exceeding 35 m/s, without generating excessive heat that would lead to premature failure.

This makes them essential for high-RPM rotating shafts found in equipment like industrial compressors and automotive turbochargers.

Extreme Temperature Resilience

PTFE seals operate reliably across a vast temperature spectrum, typically from -53°C to 232°C (-63°F to 450°F).

This wide operating window is why they are specified for aerospace applications, from jet engine gearboxes to auxiliary power units (APUs), where components must endure rapid and extreme temperature fluctuations.

Unmatched Chemical Inertness

PTFE is one of the most chemically inert materials available. It is virtually unaffected by corrosive compounds, acids, solvents, and other aggressive media.

This makes it the default choice for equipment in the chemical processing, pharmaceutical, and food and beverage industries, where seal integrity cannot be compromised by the media being handled.

Dry and Abrasive Media Tolerance

The low-friction nature of PTFE allows it to perform well in dry-running applications or with abrasive media where traditional seals would wear out rapidly.

This is a critical advantage in equipment like screw compressors, which can demand over 40,000 maintenance-free hours of operation.

A Look at Key Industrial Applications

The unique properties of PTFE directly translate into its use across several high-stakes industries where performance and durability are paramount.

Aerospace and Defense

In this sector, reliability is a matter of safety. PTFE seals are used in turbine engines, starters, fuel pumps, and flap actuators on both commercial and military aircraft. They are designed to handle high speeds, wide temperature ranges, and pressures up to 1.7 BAR.

Automotive and Racing

High-performance automotive applications, especially in racing, push components to their limits. PTFE seals are found in turbochargers, high-performance engines, and transmissions where high temperatures and rotational speeds are standard.

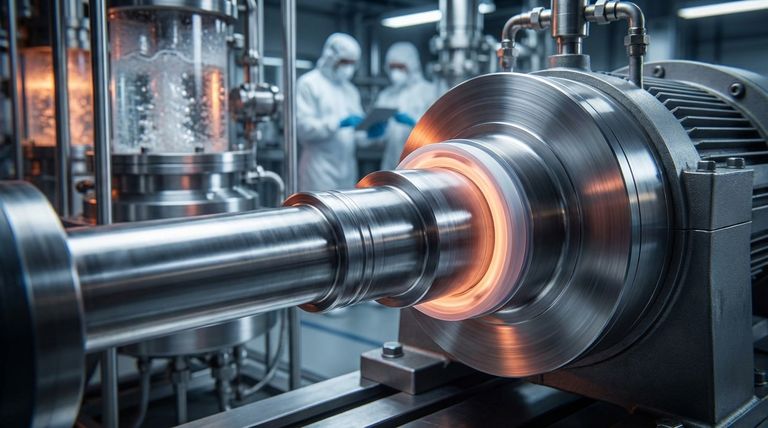

Industrial Machinery

PTFE seals are workhorses in heavy industrial settings. They are critical components in industrial air compressors, screw compressors, pumps, and gearboxes, providing long-term, reliable sealing in conditions that would destroy lesser materials.

Processing Industries

For industries like chemical manufacturing, pharmaceuticals, and food production, preventing contamination and leakage is crucial. The chemical inertness of PTFE seals ensures they do not react with or contaminate the product, guaranteeing process purity.

Understanding the Selection Criteria

While powerful, a PTFE seal is not a one-size-fits-all solution. Proper selection is critical to achieving the desired performance and longevity.

It's Not a Universal Solution

PTFE seals are specialized components. They are engineered for challenging conditions that exceed the capabilities of common elastomers. In simple, low-speed, and non-aggressive applications, a standard elastomer seal is often more cost-effective.

Key Factors for Proper Selection

To ensure optimal performance, the seal must be matched precisely to its operating environment. Critical factors include:

- Shaft Speed: The surface velocity of the rotating shaft.

- Operating Temperatures: Both the minimum and maximum expected temperatures.

- System Pressures: The pressure the seal must contain.

- Media: The specific chemical or fluid being sealed.

Making the Right Choice for Your Application

Choosing the correct seal requires aligning its capabilities with the primary challenge of your environment.

- If your primary focus is extreme speed and temperature: PTFE is the ideal choice for applications like aerospace systems, turbochargers, and high-RPM industrial equipment.

- If your primary focus is chemical compatibility: Select PTFE for pumps, mixers, and reactors in chemical, pharmaceutical, or food processing environments.

- If your primary focus is long-term reliability in harsh conditions: Use PTFE for critical machinery like industrial compressors where maintenance is difficult and uptime is essential.

By understanding these core principles, you can confidently select a sealing solution that ensures both performance and longevity in the most demanding environments.

Summary Table:

| Environment Characteristic | Common Industries / Applications |

|---|---|

| High Rotational Speeds (>35 m/s) | Turbochargers, Compressors, High-RPM Machinery |

| Extreme Temperatures (-53°C to 232°C) | Aerospace, Automotive, Defense Systems |

| Aggressive Chemicals & Solvents | Chemical Processing, Pharmaceutical, Food & Beverage |

| Dry or Abrasive Media | Screw Compressors, Pumps, Industrial Gearboxes |

Need a reliable sealing solution for your demanding application?

KINTEK specializes in manufacturing high-performance, custom PTFE components—including seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors. Our precision production and custom fabrication services, from prototypes to high-volume orders, ensure you get a component engineered for longevity and peak performance in your specific environment.

Contact KINTEK today to discuss your project requirements and discover how our PTFE expertise can solve your toughest sealing challenges.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Bottles for Diverse Industrial Applications

People Also Ask

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments