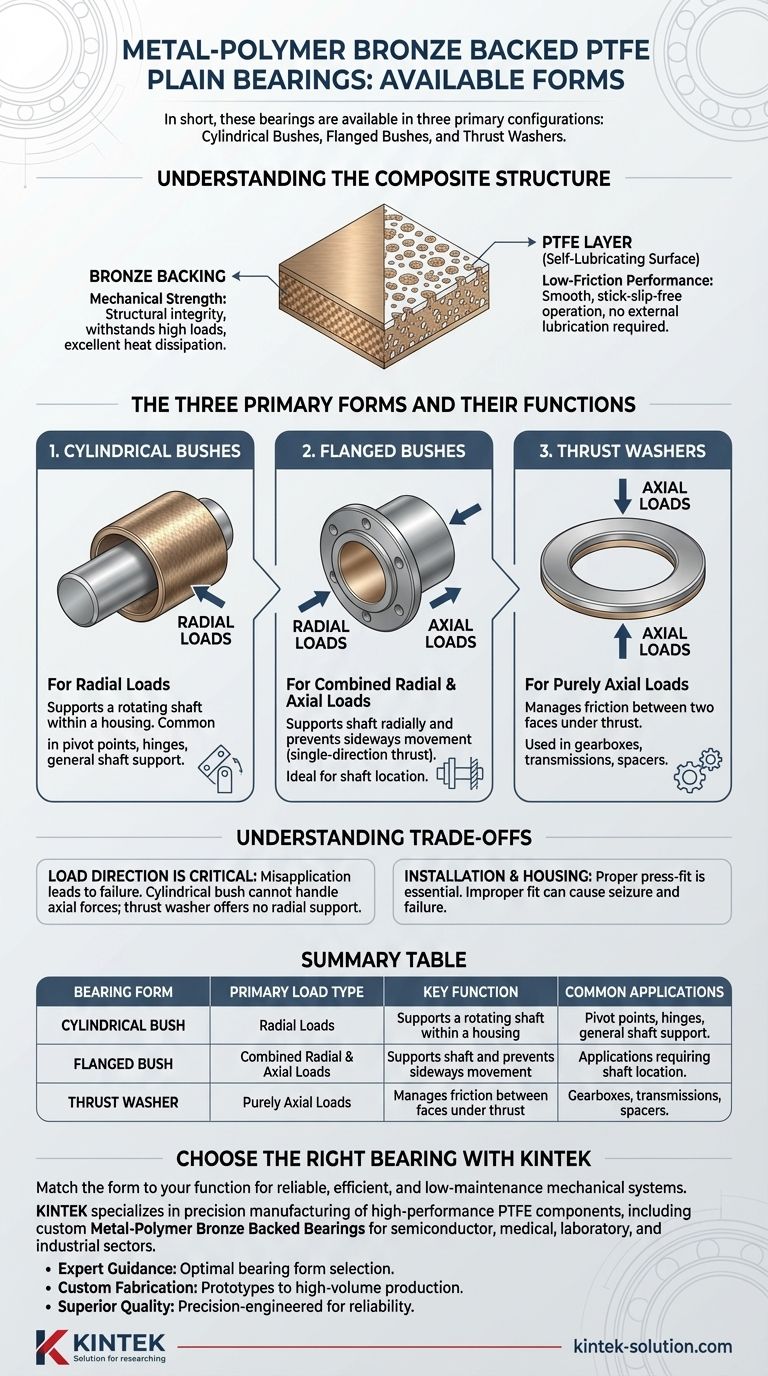

In short, these bearings are available in three primary configurations. They are manufactured as cylindrical bushes, flanged bushes, and thrust washers. This variety allows engineers to select a precise form factor that matches the specific load and motion requirements of their mechanical design.

The form of a metal-polymer bearing is not just about its shape; it's a direct reflection of its intended function. Each configuration—bush, flanged bush, or washer—is engineered to manage a specific type of mechanical load: radial, axial, or a combination of both.

Understanding the Core Components

Before examining the different forms, it's essential to understand the composite structure that gives these bearings their unique properties. They are not a single material but a layered system.

The Bronze Backing: Mechanical Strength

The outer layer is a bronze backing. This component provides the bearing's structural integrity, allowing it to be press-fit into a housing and withstand high mechanical loads without deforming. It also serves as an excellent conductor for dissipating heat generated by friction.

The PTFE Layer: Low-Friction Performance

Bonded to the backing is a porous bronze interlayer impregnated with a PTFE (Polytetrafluoroethylene) compound. This layer provides a self-lubricating, low-friction surface that makes direct contact with the moving part. The PTFE ensures smooth, stick-slip-free operation without the need for external grease or oil.

The Three Primary Forms and Their Functions

The combination of a strong backing and a low-friction surface is configured into three standard shapes, each designed to solve a different engineering problem.

Cylindrical Bushes: For Radial Loads

The most common form is the cylindrical bush, also known as a sleeve bearing. This simple tube shape is designed to support a rotating shaft and handle radial loads—forces that act perpendicular to the shaft's axis.

They are press-fit into a housing, providing a smooth, durable bore for the shaft to rotate within. This is the standard choice for pivot points, hinges, and general shaft support.

Flanged Bushes: For Combined Radial and Axial Loads

A flanged bush is a cylindrical bush with a lip, or flange, at one end. This design is engineered to manage both radial loads and axial loads (thrust) in a single direction.

The cylindrical body supports the shaft radially, while the flange provides a wear surface that prevents the shaft assembly from moving sideways. This is ideal for applications where a component on a shaft might otherwise slide out of position.

Thrust Washers: For Purely Axial Loads

A thrust washer is a flat, ring-shaped bearing. Its sole purpose is to manage axial loads between two rotating components. It acts as a spacer and a low-friction interface, preventing wear between parts that are pushing against each other.

Unlike bushes, thrust washers do not support radial loads. They are commonly used in gearbox assemblies, vehicle transmissions, and other applications where axial forces are the primary concern.

Understanding the Trade-offs

Choosing the right form is critical, as a mismatch between the bearing and the application can lead to premature failure. The primary considerations are load direction and housing design.

Load Direction is Critical

The most common mistake is using a bearing form that cannot support the loads it will experience. A cylindrical bush cannot handle axial forces, and a thrust washer offers no radial support. Misapplying these components will result in rapid wear and system failure.

Installation and Housing

The performance of these bearings, particularly cylindrical and flanged bushes, is highly dependent on a proper press-fit installation. The housing bore must be machined to precise tolerances. An improper fit can compress the bearing and reduce its internal clearance, leading to seizure and failure.

Making the Right Choice for Your Application

Selecting the correct form is the foundation of a successful design. Your decision should be guided entirely by the type of motion and force you need to manage.

- If your primary focus is supporting a rotating shaft within a housing: A cylindrical bush is the standard, efficient solution for radial loads.

- If your primary focus is supporting a shaft while also preventing its sideways movement: A flanged bush provides both radial and single-direction axial support in one component.

- If your primary focus is managing friction between two faces moving against each other: A thrust washer is designed specifically for these purely axial loads.

By matching the bearing's form to its function, you create a more reliable, efficient, and low-maintenance mechanical system.

Summary Table:

| Bearing Form | Primary Load Type | Key Function | Common Applications |

|---|---|---|---|

| Cylindrical Bush | Radial Loads | Supports a rotating shaft within a housing. | Pivot points, hinges, general shaft support. |

| Flanged Bush | Combined Radial & Axial Loads | Supports shaft and prevents sideways movement. | Applications requiring shaft location. |

| Thrust Washer | Purely Axial Loads | Manages friction between faces under thrust. | Gearboxes, transmissions, spacers. |

Need the Right Bearing for Your Application?

KINTEK specializes in the precision manufacturing of high-performance PTFE components, including custom Metal-Polymer Bronze Backed Bearings. Whether you need a standard form or a custom-designed solution for the semiconductor, medical, laboratory, or industrial sectors, we deliver the durability and low-friction performance your application demands.

We provide:

- Expert Guidance: Help you select the optimal bearing form (bush, flanged bush, or washer) for your specific load requirements.

- Custom Fabrication: From prototypes to high-volume production, tailored to your exact specifications.

- Superior Quality: Precision-engineered components that ensure reliability and long service life.

Let's engineer a solution for you. Contact KINTEK today to discuss your project!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Rods for Advanced Industrial Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

People Also Ask

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability