At their core, Teflon encapsulated O-rings are a specialized sealing solution designed for static or slow, semi-dynamic applications that demand both the extreme chemical inertness of Teflon and the reliable sealing force of a rubber elastomer. They are most suitable for environments where an aggressive chemical medium would quickly degrade a standard rubber O-ring, but where the rigidity and poor memory of a solid Teflon ring would fail to create a dependable, long-term seal.

The central takeaway is that an encapsulated O-ring is not simply a "better" O-ring; it's a hybrid component that solves a specific problem. It bridges the gap between the chemical immunity of PTFE and the mechanical flexibility of an elastomer, making it the ideal choice for sealing harsh chemicals in static assemblies.

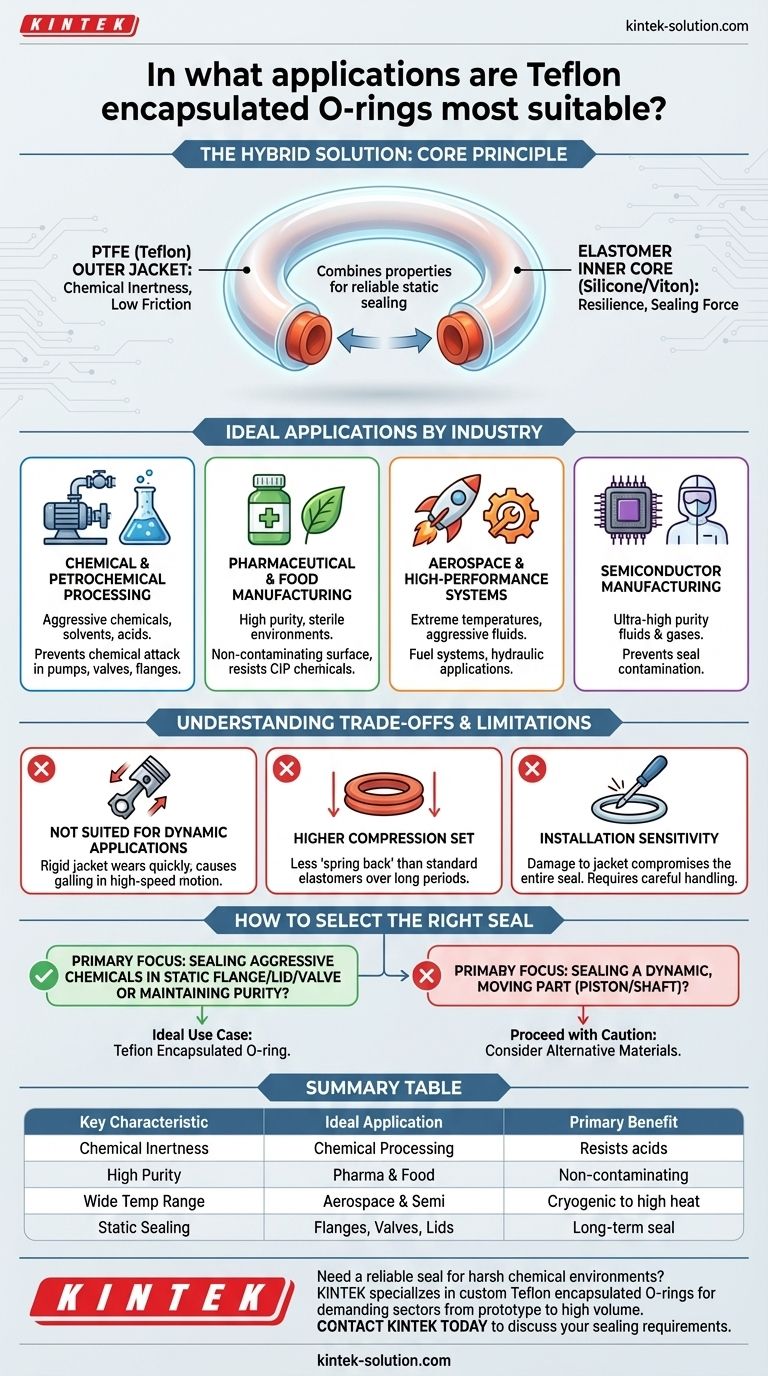

The Core Principle: A Hybrid for Demanding Jobs

To understand where these O-rings excel, you must first understand their construction. They are a composite seal, not a homogenous material.

Combining Chemical Inertness with Elasticity

A Teflon encapsulated O-ring consists of two parts: a seamless outer jacket made of PTFE (Teflon) and an inner core made of a standard elastomer, typically Silicone or Viton (FKM).

This design creates a seal that exhibits the properties of both materials.

The Teflon Outer Jacket

The outer jacket is the component that interfaces directly with the operating environment. Its primary role is to provide near-universal chemical resistance, protecting the inner core from aggressive acids, solvents, and other media that would cause it to swell, harden, or dissolve.

The Elastomer Inner Core

The inner core provides the "liveliness" or resilience that solid Teflon lacks. This elastomer core provides the constant, uniform force required to maintain a seal under pressure. It has excellent "memory," meaning it can return to its original shape after compression, ensuring a tight seal over a long service life.

Ideal Applications by Industry

This unique hybrid design makes encapsulated O-rings indispensable in several high-stakes industries where seal failure is not an option.

Chemical and Petrochemical Processing

These O-rings are used extensively in pumps, valves, and flange connections that handle aggressive chemicals, solvents, and acids. The Teflon jacket prevents chemical attack, ensuring process integrity and preventing leaks of hazardous materials.

Pharmaceutical and Food Manufacturing

In these environments, purity is paramount. The non-contaminating surface of the Teflon jacket prevents leaching and ensures the product remains sterile. They also withstand harsh sterilization and clean-in-place (CIP) chemicals.

Aerospace and High-Performance Systems

Used in fuel systems and hydraulic applications, encapsulated O-rings provide reliable sealing against aggressive fluids and function across a wide temperature range, from cryogenic to high heat.

Semiconductor Manufacturing

For handling ultra-high purity fluids and gases, the inertness of the Teflon surface is critical. It prevents the seal itself from becoming a source of contamination, which is vital for semiconductor fabrication processes.

Understanding the Trade-offs and Limitations

While powerful, encapsulated O-rings are not a universal solution. Using them in the wrong application can lead to premature failure.

Not Suited for Dynamic Applications

The primary limitation is their performance in dynamic sealing. The Teflon jacket is relatively rigid and has a higher coefficient of friction than most elastomers. In high-speed reciprocating or rotating applications, it can wear quickly or cause galling on the shaft.

Higher Compression Set

Compared to a standard elastomer O-ring, an encapsulated version does not "spring back" as effectively after being compressed for a long time. This is why they are ideal for static face or flange seals, where they are compressed and left undisturbed.

Installation Sensitivity

The Teflon jacket provides the chemical protection, and any damage to it compromises the entire seal. A scratch, nick, or crease during installation can create a leak path directly to the vulnerable elastomer core, leading to rapid failure. Careful installation with proper lubrication is critical.

How to Select the Right Seal for Your Goal

Making the right choice comes down to a clear understanding of your application's primary demand.

- If your primary focus is sealing aggressive chemicals in a static flange, lid, or valve: This is the ideal use case for a Teflon encapsulated O-ring.

- If your primary focus is maintaining system purity in a pharmaceutical or semiconductor process: The inert Teflon surface makes this an excellent choice for static connections.

- If your primary focus is sealing a dynamic, moving part like a piston or rotating shaft: You should proceed with caution and strongly consider a different material, such as a high-performance elastomer or a solid PTFE O-ring designed for low friction.

Ultimately, choosing the right seal is about matching the material's strengths to the precise mechanical, chemical, and thermal demands of your application.

Summary Table:

| Key Characteristic | Ideal Application | Primary Benefit |

|---|---|---|

| Chemical Inertness | Chemical Processing | Resists acids, solvents |

| High Purity | Pharma & Food | Non-contaminating surface |

| Wide Temp Range | Aerospace & Semiconductor | Cryogenic to high heat |

| Static Sealing | Flanges, Valves, Lids | Long-term, reliable seal |

Need a reliable seal for harsh chemical environments? KINTEK specializes in manufacturing high-precision PTFE components, including custom Teflon encapsulated O-rings. Our seals are designed for the demanding environments of the semiconductor, medical, laboratory, and industrial sectors. We offer custom fabrication from prototypes to high-volume orders, ensuring you get the exact seal for your application.

Contact KINTEK today to discuss your sealing requirements and get a solution that guarantees performance and longevity.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

People Also Ask

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers