In industrial and scientific settings, PTFE (Polytetrafluoroethylene) balls are most commonly used in applications like chemical pumps, check valves, light-load bearings, and seals. Their selection is driven by a unique set of material properties that allow them to function in demanding environments where other materials would quickly corrode or fail.

The core reason for using PTFE balls is their trifecta of key properties: extreme chemical inertness, exceptionally low friction (lubricity), and high heat resistance. This makes them the ideal choice for components that must operate reliably while exposed to harsh chemicals or in applications where traditional lubrication is not an option.

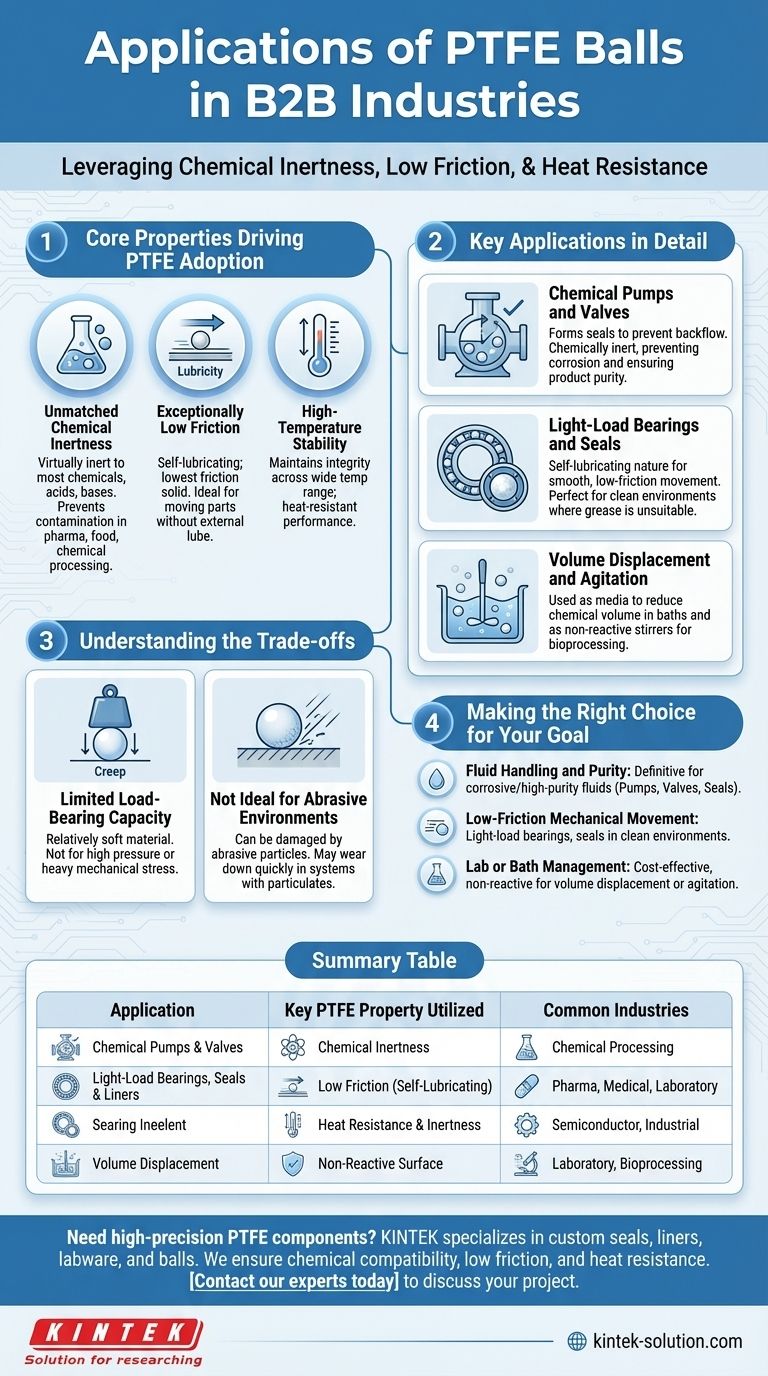

The Core Properties Driving PTFE Adoption

The utility of PTFE balls is not based on a single characteristic, but on the powerful combination of several unique material traits. Understanding these properties is key to understanding their applications.

Unmatched Chemical Inertness

PTFE is virtually inert and does not react with the vast majority of industrial chemicals, acids, and bases.

This makes it an essential material in industries like chemical processing, pharmaceuticals, and food manufacturing, where preventing contamination and material degradation is paramount.

Exceptionally Low Friction

PTFE has one of the lowest coefficients of friction of any solid material, often compared to wet ice on wet ice.

This inherent lubricity means it can be used in moving parts like bearings and seals without requiring external lubricants, which could otherwise contaminate a system.

High-Temperature Stability

PTFE can operate consistently across a wide range of temperatures, maintaining its structural integrity in many demanding industrial processes. This heat resistance ensures reliable performance where other polymers would melt or deform.

Key Applications in Detail

These core properties translate directly into specific, high-value applications across various sectors.

Chemical Pumps and Valves

In chemical handling pumps and check valves, PTFE balls are often used to create a seal that prevents the backflow of fluid.

Because the balls are chemically inert, they will not corrode or contaminate the process fluid, ensuring both the longevity of the equipment and the purity of the product.

Light-Load Bearings and Seals

The self-lubricating nature of PTFE makes it ideal for light-load ball bearings and seals.

These components are crucial in machinery where smooth, low-friction movement is required, especially in environments where adding oil or grease is impossible or undesirable.

Volume Displacement and Agitation

In laboratory and industrial settings, PTFE balls are used as volume displacement media in chemical baths. Filling a bath with inert balls reduces the amount of expensive or hazardous chemicals needed to reach a certain fluid level.

They are also used as non-reactive stirrers for mixing chemicals in bioprocessing and pharmaceutical applications.

Understanding the Trade-offs

While extremely useful, PTFE is not a universal solution. An expert understands its limitations as well as its strengths.

Limited Load-Bearing Capacity

PTFE is a relatively soft material. This is why its use in bearings is specified for "light loads." Under high pressure or heavy mechanical stress, PTFE can deform, a phenomenon known as "creep."

Not Ideal for Abrasive Environments

The material's softness also means it can be damaged by abrasive particles. In systems with significant particulate matter, PTFE components may wear down more quickly than harder materials.

Making the Right Choice for Your Goal

Selecting PTFE should be a deliberate decision based on the specific demands of your application.

- If your primary focus is fluid handling and purity: PTFE is the definitive choice for components in pumps, valves, and seals that handle corrosive or high-purity fluids.

- If your primary focus is low-friction mechanical movement: Use PTFE for light-load bearings and seals, especially in clean environments or where external lubrication is not feasible.

- If your primary focus is lab or bath management: Consider PTFE balls for a cost-effective and non-reactive solution for volume displacement or chemical agitation.

Ultimately, leveraging PTFE's unique properties in the right context ensures operational reliability and longevity where conventional materials cannot compete.

Summary Table:

| Application | Key PTFE Property Utilized | Common Industries |

|---|---|---|

| Chemical Pumps & Valves | Chemical Inertness | Chemical Processing, Pharma |

| Light-Load Bearings | Low Friction (Self-Lubricating) | Medical, Laboratory |

| Seals & Liners | Heat Resistance & Inertness | Semiconductor, Industrial |

| Volume Displacement | Non-Reactive Surface | Laboratory, Bioprocessing |

Need high-precision PTFE components for your application? KINTEK specializes in manufacturing custom PTFE seals, liners, labware, and balls for semiconductor, medical, laboratory, and industrial applications. We ensure chemical compatibility, low friction performance, and heat resistance for your most demanding environments.

Contact our experts today to discuss your project requirements—from prototypes to high-volume production.

Visual Guide

Related Products

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What materials are used for PTFE balls? A Guide to Virgin PTFE vs. Filled Composites

- What are the key features of Teflon balls? Unlock Superior Performance in Demanding Environments

- What are PTFE balls made of and what are their key properties? Unlock Superior Chemical & Thermal Performance

- What are the common applications of PTFE balls? Leverage Unmatched Chemical Resistance & Low Friction

- What temperature range can PTFE balls withstand? Unlock Extreme Thermal Stability from -200°C to 260°C