To properly maintain PTFE shovels, they must be cleaned thoroughly after each use with mild detergents and stored in a clean, dry environment. It is critical to protect them from direct sunlight, extreme heat, and abrasive materials to preserve their non-stick and chemically inert surface.

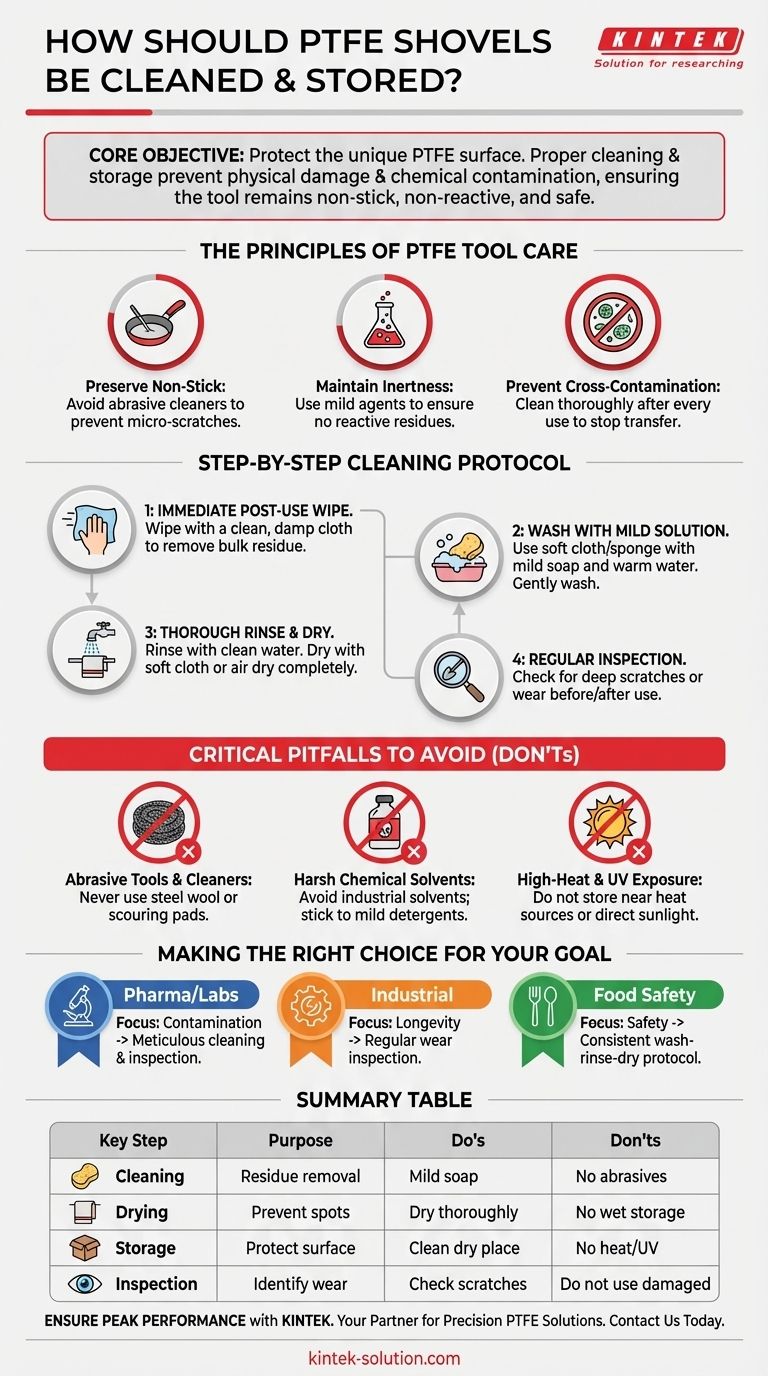

The core objective of PTFE shovel maintenance is to protect its unique surface integrity. Proper cleaning and storage prevent physical damage and chemical contamination, ensuring the tool remains non-stick, non-reactive, and safe for its intended application.

The Principles of PTFE Tool Care

Understanding why specific care is needed is the key to maximizing the lifespan and performance of your PTFE tools. The material's value lies in its unique properties, which can be compromised by improper handling.

Preserving the Non-Stick Surface

The primary benefit of PTFE is its extremely low-friction, non-stick surface. Using abrasive cleaners or scouring pads will create micro-scratches.

These scratches trap materials, negate the non-stick properties, and create sites for potential contamination, defeating the purpose of using PTFE in the first place.

Maintaining Chemical Inertness

PTFE is known for its resistance to most chemicals. However, this integrity relies on an undamaged surface.

Proper cleaning with mild, approved agents ensures that no residues are left behind that could react with materials in subsequent uses.

Preventing Cross-Contamination

In laboratory, pharmaceutical, or food processing environments, preventing cross-contamination is non-negotiable.

Thoroughly cleaning residues from a PTFE shovel after every use ensures that compounds from one batch do not get introduced into another.

A Step-by-Step Cleaning and Maintenance Protocol

Follow a consistent process to ensure your PTFE shovels remain in optimal condition.

Step 1: Immediate Post-Use Wiping

As soon as you are finished using the shovel, wipe it down with a clean, damp cloth.

This removes the bulk of any residue before it has a chance to dry and harden, making the full cleaning process much easier.

Step 2: Washing with a Mild Solution

For a thorough cleaning, use a soft cloth or sponge with a solution of mild soap and warm water.

Gently wash all surfaces of the shovel to remove any remaining material.

Step 3: Thorough Rinsing and Drying

Rinse the shovel completely with clean water to remove all traces of the cleaning agent.

Dry the shovel thoroughly with a soft cloth or allow it to air dry completely before storage. This prevents water spots and potential microbial growth.

Step 4: Regular Inspection

Before and after each use, perform a quick visual inspection of the shovel.

Look for deep scratches, discoloration, or signs of wear and degradation. A compromised tool should be replaced to avoid risks of contamination or failure.

Critical Pitfalls to Avoid

What you don't do is just as important as what you do. Avoiding these common mistakes is essential for protecting your tools.

Abrasive Tools and Cleaners

Never use steel wool, scouring pads, or abrasive chemical powders. These items will permanently damage the PTFE surface, rendering it ineffective and difficult to clean.

Harsh Chemical Solvents

While PTFE is highly resistant, you should avoid cleaning it with harsh industrial solvents or unknown chemicals unless explicitly approved by the manufacturer. Stick to mild detergents for routine cleaning.

High-Heat and UV Exposure

Do not store PTFE shovels near high-heat sources like ovens or motors.

Likewise, avoid leaving them in direct sunlight for extended periods. Both extreme heat and UV radiation can cause the material to degrade and become brittle over time.

Making the Right Choice for Your Goal

Your specific application should guide the intensity of your maintenance protocol.

- If your primary focus is preventing cross-contamination (pharma, labs): Meticulous cleaning, thorough rinsing, and pre-use inspection are your most critical steps.

- If your primary focus is tool longevity (industrial use): Regular inspection for physical wear, scratches, and gouges is paramount to prevent tool failure.

- If your primary focus is food safety (culinary, processing): A consistent wash-rinse-dry protocol using food-safe mild detergents is sufficient to ensure safety and performance.

By following these guidelines, you ensure your PTFE shovel remains a reliable, safe, and effective asset in your workflow.

Summary Table:

| Key Maintenance Step | Purpose | Do's | Don'ts |

|---|---|---|---|

| Cleaning | Remove residues, prevent contamination | Use mild soap, warm water, soft cloth/sponge | Avoid abrasive pads, harsh chemicals, steel wool |

| Drying | Prevent water spots, microbial growth | Dry thoroughly with soft cloth or air dry | Do not store while wet |

| Storage | Protect from degradation | Store in clean, dry place | Avoid direct sunlight, extreme heat sources |

| Inspection | Identify wear, prevent failure | Check for scratches, discoloration before/after use | Do not use a damaged tool |

Ensure Peak Performance and Longevity for Your PTFE Tools

Proper maintenance is key, but it starts with a high-quality tool. KINTEK specializes in manufacturing precision PTFE components, including shovels, seals, liners, and labware, for the semiconductor, medical, laboratory, and industrial sectors. Our commitment to precision production and custom fabrication—from prototypes to high-volume orders—ensures you receive a durable, reliable product designed for your specific application.

Let us provide the right PTFE solution for your needs. Contact KINTEK today to discuss your requirements and learn how our expertise can benefit your operation.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- PTFE Chemical Solvent Sampling Spoon

- Customizable PTFE Scrapers and Shovels for Demanding Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support