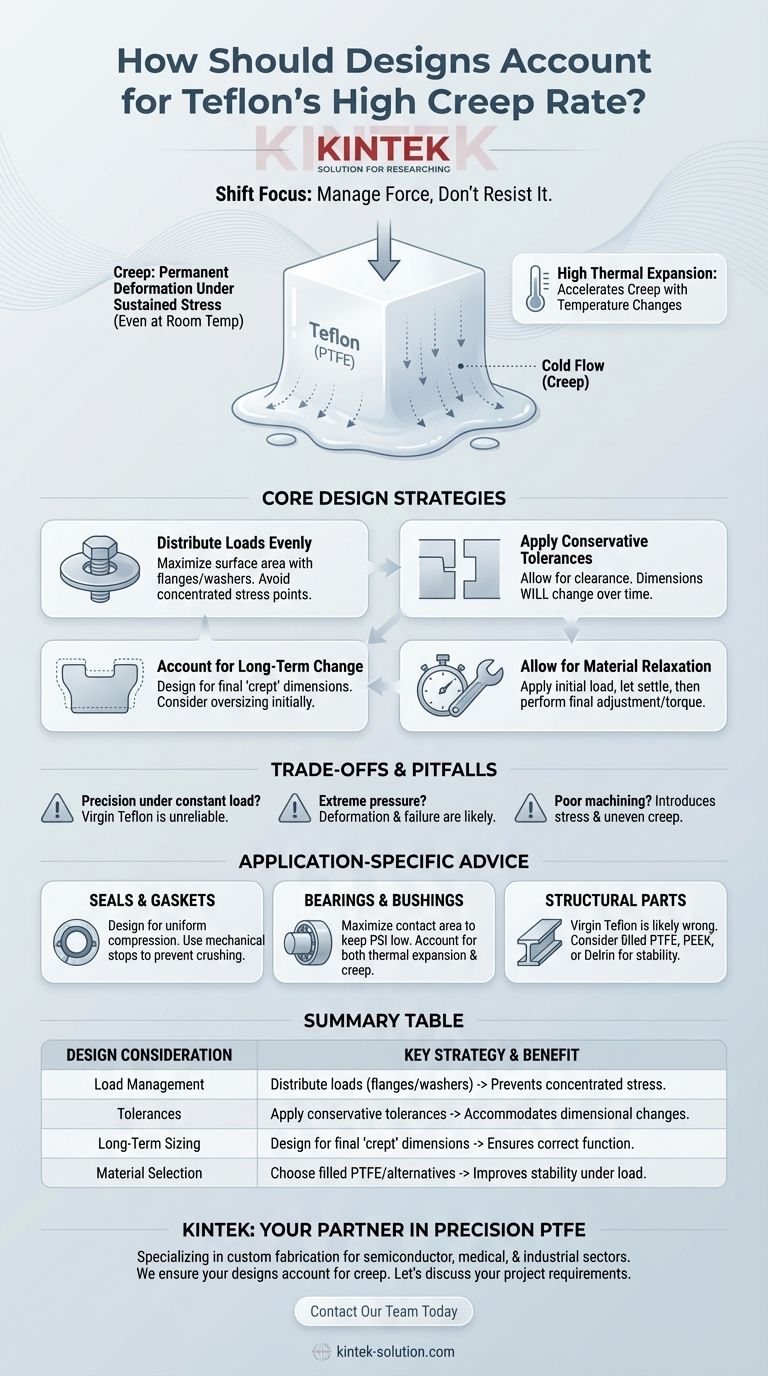

To properly design for Teflon's high creep rate, you must shift your focus from resisting force to managing it. This involves designing components that distribute loads over the widest possible area, using conservative tolerances that anticipate dimensional changes, and accounting for the material's long-term deformation under sustained stress. Never treat Teflon (PTFE) like a rigid, structural plastic.

The central challenge with Teflon is not its strength, but its tendency to "cold flow" or creep under sustained load, even at room temperature. A successful design accommodates this movement rather than attempting to prevent it, ensuring the part remains functional throughout its service life.

The Nature of Teflon Creep

Polytetrafluoroethylene (PTFE), or Teflon, is a unique material known for its softness and extremely low coefficient of friction. However, these same properties contribute to its primary design challenge: creep.

What is Creep, or "Cold Flow"?

Creep is the tendency of a solid material to deform permanently under the influence of persistent mechanical stress.

In metals, this typically occurs at high temperatures. In Teflon, it happens readily at room temperature, which is why it's often called cold flow.

The Connection Between Softness and Creep

Teflon's molecular chains are not strongly interlocked. This allows them to slip past one another when a load is applied over time, causing the part to slowly change shape.

This inherent softness makes it excellent for seals and gaskets but problematic for components that must hold a precise shape under pressure.

The Impact of Thermal Expansion

Teflon also has a very high coefficient of thermal expansion. Temperature changes will cause significant dimensional shifts, which can induce stress and accelerate the rate of creep in a constrained part.

Core Design Strategies to Manage Creep

A successful Teflon component design anticipates and manages cold flow from the very beginning.

Distribute Loads Evenly

This is the most critical principle. Concentrated stress is the primary driver of creep.

Use large-flanged bushings, washers, and generous surface areas to spread any compressive load. Avoid sharp corners or narrow features that create stress points.

Apply Conservative Tolerances

Do not design Teflon parts with extremely tight tolerances if they will be under any kind of load. The part's dimensions will change over time.

Your design and its mating components must have enough clearance to function correctly after the Teflon has settled into its long-term, deformed shape.

Account for Long-Term Dimensional Change

In the design phase, you must consider the final, "crept" dimensions of the part, not just its initial machined state.

This may involve intentionally oversizing a part with the knowledge that it will compress or deform to its final functional size over time.

Allow for Material Relaxation

In some assembly processes, it can be beneficial to apply an initial load, allow the material to creep and relax for a period, and then perform a final torque or adjustment.

Understanding the Trade-offs and Pitfalls

Using Teflon effectively means respecting its limitations. Ignoring them leads to component failure.

The Unavoidable Challenge of Precision

If a component must maintain high-precision dimensions under a constant load, virgin Teflon is often the wrong choice. The material's tendency to creep makes this fundamentally unreliable.

Deformation Under Extreme Pressure

Teflon is not a high-strength, structural material. It is designed for low-friction surfaces, chemical resistance, and sealing—not for bearing significant loads.

Any design that subjects a Teflon part to high, focused pressure is destined to fail as the material flows away from the stress point.

Machining Can Introduce Stress

The softness that contributes to creep also makes Teflon challenging to machine. Poor machining practices can generate heat and introduce unbalanced stresses into a part, predisposing it to warp or creep unevenly later.

Making the Right Choice for Your Application

Your design strategy should be dictated entirely by the component's function.

- If your primary focus is creating a seal or gasket: Design for uniform compression and use mechanical stops to prevent over-tightening, which would excessively crush the material.

- If your primary focus is a low-friction bearing or bushing: Maximize the contact surface area to keep the pressure (PSI) as low as possible and ensure clearances account for both thermal expansion and creep.

- If your primary focus is a dimensionally stable structural part: Recognize that virgin Teflon is likely the wrong material and consider a "filled" grade of PTFE or a different polymer like PEEK or Delrin.

By designing with Teflon's inherent material flow in mind, you can leverage its exceptional properties while ensuring long-term reliability.

Summary Table:

| Design Consideration | Key Strategy | Benefit |

|---|---|---|

| Load Management | Distribute loads over wide areas using flanges/washers | Prevents concentrated stress points that accelerate creep |

| Tolerances | Apply conservative tolerances and allow for clearance | Accommodates dimensional changes from cold flow |

| Long-Term Sizing | Design for final 'crept' dimensions, potentially oversizing initially | Ensures part functions correctly after settling |

| Material Selection | Choose filled PTFE or alternative polymers for precision parts | Improves dimensional stability under sustained load |

Struggling with Teflon component design? KINTEK specializes in manufacturing precision PTFE components (seals, liners, labware, and more) for the semiconductor, medical, laboratory, and industrial sectors. Our expertise in custom fabrication—from prototypes to high-volume orders—ensures your designs account for material behavior like creep, delivering parts that perform reliably. Let's discuss your project requirements – contact our team today for a solution tailored to your needs.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Bottles for Diverse Industrial Applications

People Also Ask

- What is the hardness range of PTFE on the Shore D scale? Leveraging Its Softness for Superior Performance

- What are some important physical property values for PTFE? Master Its Extreme Performance for Demanding Applications

- When and by whom was PTFE discovered? A Tale of Accidental Innovation

- What are some applications of CNC machined PTFE parts? Critical Components for Medical, Electrical & Food Industries

- How does PTFE compare to other low-friction plastics like UHMW-PE and Nylon? A Guide to Material Selection