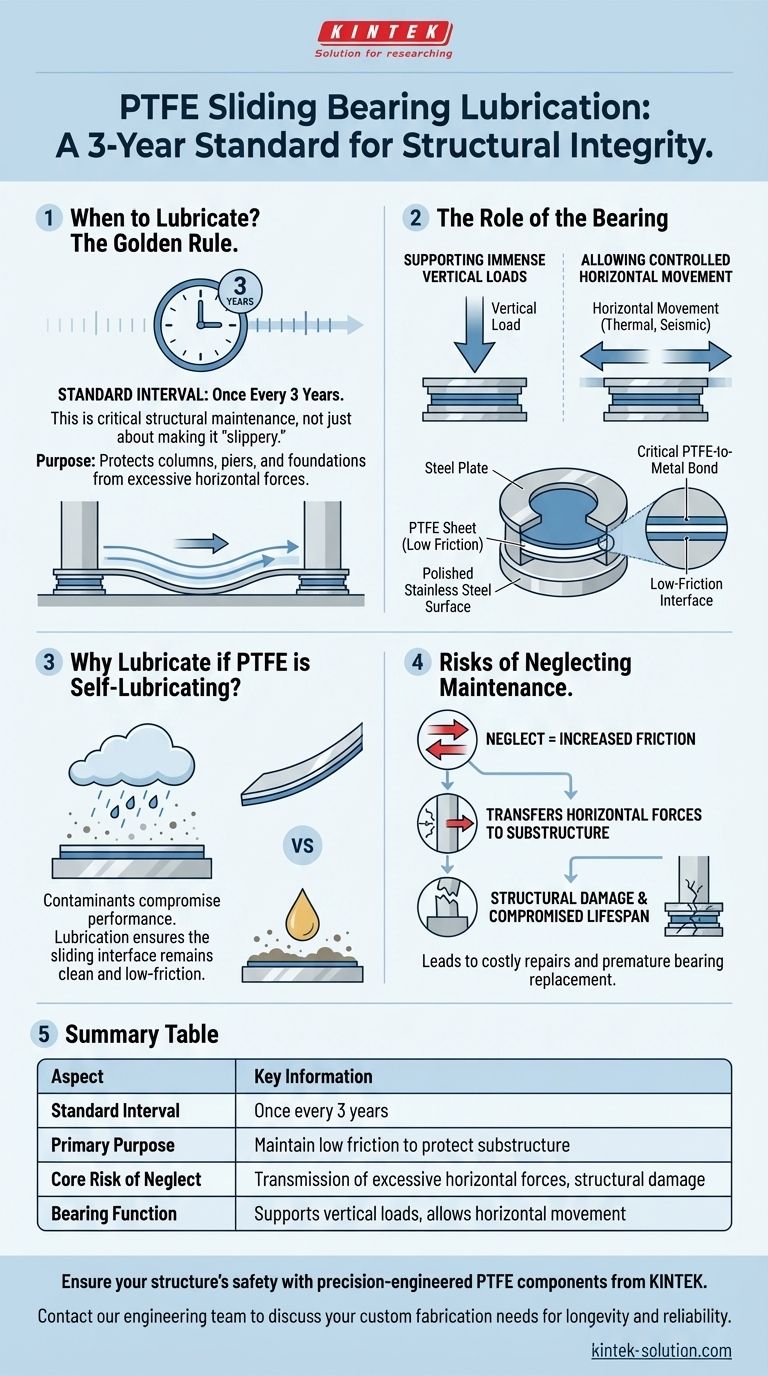

As a general engineering standard, PTFE sliding bearings should be lubricated approximately once every three years. This maintenance is not merely for the bearing itself but is a critical procedure to ensure the entire structure performs as designed by maintaining low friction and preventing the transmission of excessive horizontal forces to the substructure.

The core takeaway is that lubricating a PTFE bearing is not about making it "slippery." It is a crucial structural maintenance task designed to protect columns, piers, and foundations from unintended forces that arise when a bearing's friction increases over time.

The Role of a PTFE Sliding Bearing

What is its core function?

A PTFE sliding bearing is a structural component designed to serve two primary purposes simultaneously. It must support immense vertical loads while allowing for controlled, low-friction horizontal movement.

This movement accommodates forces like thermal expansion and contraction, material creep, or seismic activity, preventing these stresses from being transferred to the support structure.

How is it constructed?

The typical design involves two primary steel plates. One plate has a sheet of Polytetrafluoroethylene (PTFE) bonded to it, while the mating plate features a highly polished stainless steel surface.

The low-friction interface between the PTFE and the stainless steel permits the desired translation in longitudinal and transverse directions.

Why the PTFE-to-metal bond is critical

The high vertical loads on the bearing create intense shear forces that act directly on the bond between the PTFE layer and its steel backing plate.

A robust, reliable bond is essential for the bearing's function and longevity, requiring precise manufacturing and surface preparation.

The "Why" Behind the Lubrication Schedule

Isn't PTFE self-lubricating?

While PTFE is known for its extremely low coefficient of friction, this property can be compromised in real-world conditions. The bearing surfaces are exposed to dust, moisture, and other environmental contaminants.

Lubrication helps ensure the sliding interface remains clean and operates at the low friction values assumed in the original structural design.

Maintaining design performance

Engineers design a structure assuming the bearings will operate with a specific, low coefficient of friction.

The three-year lubrication cycle is a preventative measure to keep the bearing's performance within this design specification, ensuring it moves freely and absorbs horizontal forces as intended.

The Risks of Neglecting Maintenance

Increased horizontal force transmission

This is the single most critical risk. If a bearing's friction increases because of contamination or lack of lubrication, it may not slide freely.

Instead of accommodating movement, the "stuck" bearing will begin to transfer horizontal forces from thermal expansion or other sources directly into the substructure (the columns or piers supporting it).

Potential for structural damage

Substructures are typically designed to handle vertical loads, not significant, unanticipated horizontal forces.

This unintended force transmission can lead to cracking, spalling, or other forms of distress in the very foundations of the structure, leading to complex and expensive repairs.

Compromised bearing lifespan

Higher friction leads to accelerated wear and abrasion of both the PTFE and the polished stainless steel surfaces. Neglecting lubrication can shorten the effective service life of the bearing, necessitating premature replacement.

A Practical Maintenance Guideline

Following a consistent schedule is the most effective way to ensure long-term structural health.

- If your primary focus is structural integrity: Adhering to the three-year lubrication schedule is a non-negotiable safety measure to prevent unintended stress on the building or bridge substructure.

- If your primary focus is long-term asset management: Regular lubrication is a low-cost preventative action that protects a critical component, extending its service life and avoiding far more costly structural repairs in the future.

Ultimately, this simple maintenance task is one of the most effective ways to preserve the safety and integrity of the entire structure.

Summary Table:

| Aspect | Key Information |

|---|---|

| Standard Interval | Once every 3 years |

| Primary Purpose | Maintain low friction to protect substructure (piers, columns) |

| Core Risk of Neglect | Transmission of excessive horizontal forces, leading to structural damage |

| Bearing Function | Supports vertical loads while allowing horizontal movement (e.g., thermal expansion) |

Ensure your structure's long-term safety and performance with precision-engineered PTFE components from KINTEK.

Just as proper lubrication is critical for PTFE bearings, using high-quality, reliably bonded PTFE parts is fundamental to your project's integrity. KINTEK specializes in manufacturing custom PTFE seals, liners, bearings, and labware for the semiconductor, medical, laboratory, and industrial sectors. Our focus on precision production and robust bonding ensures your components perform as designed, protecting your valuable assets.

Ready to specify components built for longevity and reliability? Contact our engineering team today to discuss your custom fabrication needs, from prototypes to high-volume orders.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support