In the electronics industry, Teflon is primarily utilized for its exceptional electrical insulation. Known technically as Polytetrafluoroethylene (PTFE), its unique combination of properties makes it indispensable for insulating wires, cables, and sensitive components, particularly in high-frequency and high-performance applications where standard materials would fail.

The core reason Teflon is so valuable in electronics is not just its ability to insulate, but its stability across a wide range of frequencies, temperatures, and chemical environments. This reliability makes it the material of choice for mission-critical systems where signal integrity and component protection are paramount.

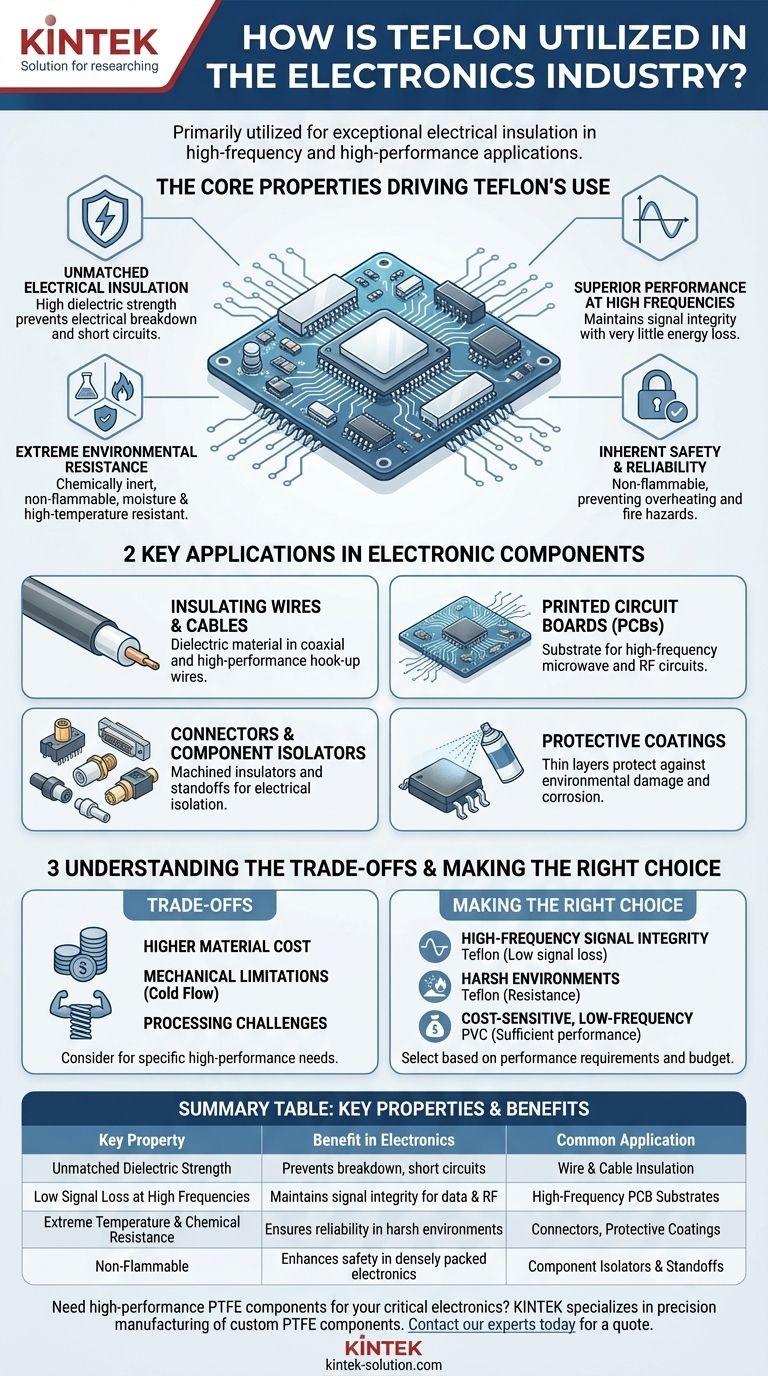

The Core Properties Driving Teflon's Use in Electronics

To understand Teflon's role, we must look beyond its non-stick reputation and focus on the specific material science characteristics that solve critical engineering challenges in electronics.

Unmatched Electrical Insulation

Teflon possesses outstanding dielectric properties, meaning it is highly resistant to conducting electricity. This prevents electrical breakdown even in high-voltage scenarios.

This makes it an ideal material for separating conductive elements and preventing short circuits, ensuring the safe and reliable operation of electronic devices.

Superior Performance at High Frequencies

In many modern electronics, signals operate at very high frequencies (e.g., in radio, radar, and high-speed data).

Teflon maintains its excellent insulating properties with very little energy loss at these frequencies. This ensures signal integrity, preventing the degradation or distortion of data as it travels through a cable or across a circuit board.

Extreme Environmental Resistance

Electronic components are often exposed to harsh conditions. Teflon is chemically inert, meaning it does not react with corrosive chemicals or solvents.

It is also highly resistant to moisture, which is critical for preventing corrosion and electrical failure. Furthermore, its ability to withstand extreme temperatures ensures stable performance in demanding applications.

Inherent Safety and Reliability

A key safety feature of Teflon is that it is non-flammable. This quality is vital in densely packed electronics where components can generate significant heat.

Using Teflon for insulation helps prevent overheating from escalating into a fire, adding a crucial layer of safety and reliability to the final product.

Key Applications in Electronic Components

These fundamental properties translate directly into several common uses throughout the industry.

Insulating Wires and Cables

This is Teflon's most common application in electronics. It is used as the dielectric material in coaxial cables and as the primary insulation on hook-up wires for high-performance systems where signal loss must be minimized.

Printed Circuit Boards (PCBs)

For high-frequency circuits, such as those used in microwave and RF communications, Teflon is often used as the substrate material for the PCB itself. Its stable dielectric properties ensure that the circuit performs as designed without signal distortion.

Connectors and Component Isolators

Teflon is machined into various shapes to serve as insulators within connectors and as standoffs for mounting components. These parts electrically isolate different sections of a circuit.

Protective Coatings

Thin layers of Teflon can be applied to sensitive electronic assemblies. This protects them from environmental factors like moisture and corrosive agents, extending the lifespan and reliability of the device.

Understanding the Trade-offs

While Teflon's performance is exceptional, it is not the default choice for every application. Its benefits come with practical considerations that engineers must weigh.

Higher Material Cost

Teflon is significantly more expensive than common insulators like PVC or polyethylene. Its use is typically reserved for applications where its specific high-performance characteristics are a strict requirement.

Mechanical Limitations

PTFE is a relatively soft material and can be susceptible to "cold flow" or creep, where the material deforms over time under mechanical pressure. This must be accounted for in designs where tight tolerances are critical.

Processing Challenges

Manufacturing components with Teflon can be more complex and costly than with other polymers. This difficulty in processing contributes to the higher overall cost of Teflon-based components.

Making the Right Choice for Your Application

Selecting the right insulating material depends entirely on the performance requirements and budget of your project.

- If your primary focus is high-frequency signal integrity: Teflon is the superior choice due to its low signal loss and stable dielectric constant.

- If your primary focus is reliability in harsh environments: Teflon's resistance to heat, moisture, and chemicals makes it essential for mission-critical components.

- If your primary focus is cost-sensitive, low-frequency applications: More common insulators like PVC will likely provide sufficient performance at a much lower cost.

Ultimately, selecting Teflon is a strategic decision to prioritize unparalleled electrical performance and environmental reliability where it matters most.

Summary Table:

| Key Property | Benefit in Electronics | Common Application |

|---|---|---|

| Unmatched Dielectric Strength | Prevents electrical breakdown and short circuits. | Wire & cable insulation. |

| Low Signal Loss at High Frequencies | Maintains signal integrity for data and RF. | High-frequency PCB substrates. |

| Extreme Temperature & Chemical Resistance | Ensures reliability in harsh environments. | Connectors, protective coatings. |

| Non-Flammable | Enhances safety in densely packed electronics. | Component isolators and standoffs. |

Need high-performance PTFE components for your critical electronics?

KINTEK specializes in the precision manufacturing of custom PTFE (Teflon) seals, liners, labware, and complex components. We serve the semiconductor, medical, laboratory, and industrial sectors, delivering the material reliability and signal integrity your high-frequency and harsh-environment applications demand.

From prototypes to high-volume production, we ensure your components meet the strictest performance standards. Contact our experts today to discuss your project requirements and get a quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Customizable PTFE Crucibles for Laboratory and Industrial Applications

People Also Ask

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability