In the electronics and semiconductor industry, Teflon (PTFE) is a critical material used for high-performance wire insulation, printed circuit boards (PCBs), and as a chemically inert component in the semiconductor manufacturing process. Its value comes from a unique combination of properties: it is an exceptional electrical insulator, is nearly impervious to chemical attack, and can withstand extreme temperatures.

The core challenge in advanced electronics is finding materials that can protect sensitive components without interfering with their performance. Teflon solves this by acting as an invisible shield, providing superior electrical insulation and chemical purity that is essential for both high-frequency applications and the pristine environment required for manufacturing semiconductors.

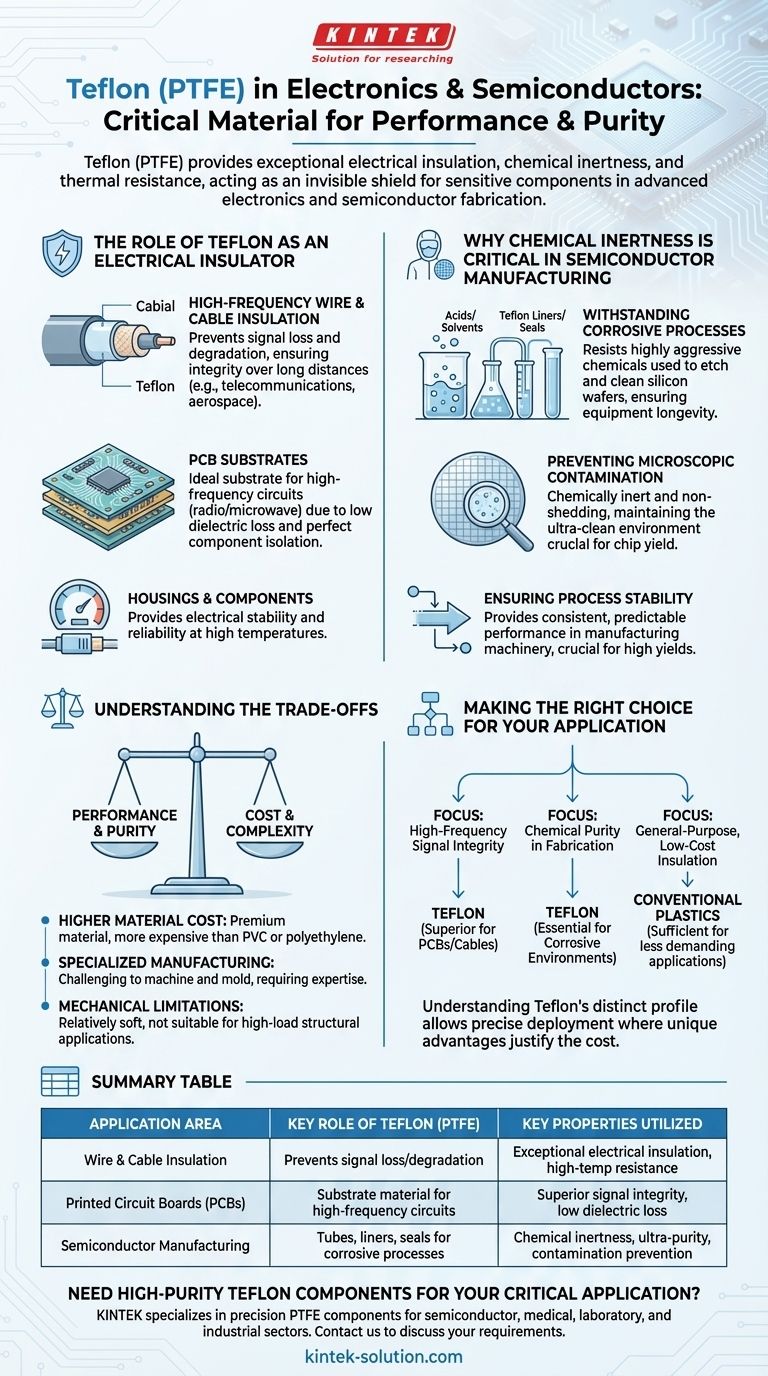

The Role of Teflon as an Electrical Insulator

In electronics, preventing signal loss and electrical interference is paramount. Teflon's molecular structure makes it one of the best insulators available, which is why it is specified for demanding applications.

Insulating High-Frequency Wires and Cables

Teflon is used as the insulating layer around high-frequency cables, such as those used in telecommunications and aerospace. Its properties prevent the electrical signal from leaking or degrading, ensuring signal integrity over long distances.

Substrates for Printed Circuit Boards (PCBs)

For high-performance electronics, especially those operating at radio or microwave frequencies, Teflon is used as the substrate material for the circuit board itself. This ensures that the components mounted on the board are perfectly isolated and that the circuits perform as designed without interference.

Housings and Components

General electrical components, gauges, and light fittings often use machined Teflon for housings or internal parts. Its ability to provide electrical stability at high temperatures ensures reliability and safety.

Why Chemical Inertness is Critical in Semiconductor Manufacturing

The process of fabricating silicon computer chips involves some ofthe most aggressive chemicals and purest environments in any industry. Teflon's resistance to virtually all chemicals makes it an indispensable material.

Withstanding Corrosive Manufacturing Processes

Semiconductor fabrication relies on highly corrosive acids and solvents to etch and clean silicon wafers. Teflon is used for tubes, liners, seals, and gaskets in this equipment because it will not break down or corrode.

Preventing Microscopic Contamination

Even a single microscopic particle can ruin a computer chip. Because Teflon is chemically inert, it does not react with process fluids or shed its own particles, helping to maintain the ultra-clean environment necessary for manufacturing reliable semiconductors.

Ensuring Process Stability

By providing chemically resistant and electrically stable components within the manufacturing machinery, Teflon helps ensure the entire fabrication process is consistent and predictable. This stability is crucial for achieving high yields of functional computer chips.

Understanding the Trade-offs

While Teflon's properties are exceptional, it is not the default choice for every application. Its selection involves clear trade-offs that engineers must consider.

Higher Material Cost

Teflon is a premium performance material and is significantly more expensive than common insulators like PVC or polyethylene. Its use is typically reserved for applications where its specific properties are a strict requirement.

Specialized Manufacturing

Machining and molding Teflon can be more challenging than working with other polymers. It requires specialized knowledge and equipment, which can add to the overall cost and complexity of producing a part.

Mechanical Limitations

While durable, Teflon is a relatively soft material. It is not suitable for high-load structural applications where mechanical strength and rigidity are the primary requirements, as it can deform under sustained pressure.

Making the Right Choice for Your Application

Selecting the correct material is a balance of performance, environment, and cost. Teflon's role is clearly defined by its unique strengths.

- If your primary focus is high-frequency signal integrity: Teflon is the superior choice for insulating wires and building PCBs to prevent signal loss and interference.

- If your primary focus is chemical purity in manufacturing: Teflon's unmatched chemical inertness makes it essential for any component exposed to corrosive chemicals in semiconductor fabrication.

- If your primary focus is general-purpose, low-cost insulation: For less demanding applications that do not involve extreme heat or chemicals, more conventional and less expensive plastics are often sufficient.

Ultimately, understanding Teflon's distinct profile of electrical, chemical, and thermal resistance allows you to deploy it precisely where its unique advantages can justify its cost.

Summary Table:

| Application Area | Key Role of Teflon (PTFE) | Key Properties Utilized |

|---|---|---|

| Wire & Cable Insulation | Prevents signal loss/degradation in high-frequency cables | Exceptional electrical insulation, high-temperature resistance |

| Printed Circuit Boards (PCBs) | Substrate material for high-frequency circuits | Superior signal integrity, low dielectric loss |

| Semiconductor Manufacturing | Tubes, liners, seals, and gaskets for corrosive processes | Chemical inertness, ultra-purity, contamination prevention |

Need High-Purity Teflon Components for Your Critical Application?

KINTEK specializes in manufacturing precision PTFE components—including seals, liners, labware, and custom parts—for the semiconductor, medical, laboratory, and industrial sectors. We ensure the material purity and performance your high-tech processes demand, from prototypes to high-volume production.

Contact KINTEK today to discuss your specific requirements and get a quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs