In the world of electronics, Teflon (PTFE) is primarily valued as a high-performance material for electrical insulation and specialized manufacturing components. Its most common applications include serving as a dielectric in printed circuit boards (PCBs) and capacitors, providing a protective coating for high-temperature wires and cables, and functioning as non-stick, chemically-inert carriers for silicon wafers during semiconductor fabrication.

Teflon's role in electronics is not about its non-stick properties but its elite combination of superior electrical insulation, extreme temperature resistance, and chemical inertness. This makes it indispensable for high-performance applications where standard materials would fail.

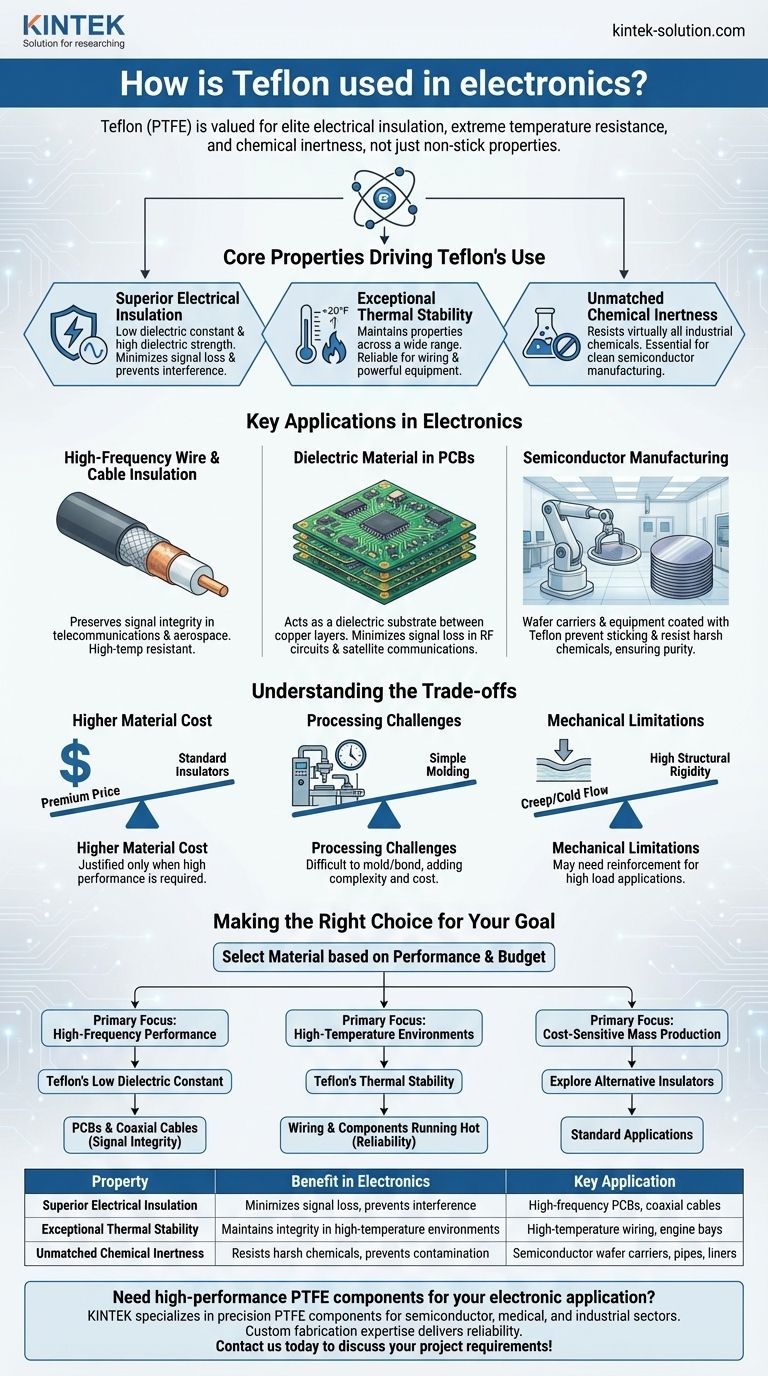

The Core Properties Driving Teflon's Use

Teflon is not chosen by accident. Its selection is a direct result of a unique set of physical and chemical characteristics that solve critical engineering challenges in electronics.

Superior Electrical Insulation

Teflon has an exceptionally low dielectric constant and high dielectric strength. This means it is an excellent electrical insulator that minimizes signal loss and prevents electrical interference, especially at high frequencies.

This property is crucial for maintaining the integrity of signals in high-speed data cables and advanced communication systems.

Exceptional Thermal Stability

Electronic components generate heat, and Teflon excels in these environments. It maintains its structural integrity and insulating properties across a very wide temperature range, far exceeding that of common plastics like PVC.

This makes it a reliable choice for wiring inside powerful equipment or in applications exposed to extreme operating conditions.

Unmatched Chemical Inertness

Teflon is resistant to virtually all industrial chemicals and solvents. This is critical in semiconductor manufacturing, where harsh chemicals are used for cleaning and etching wafers.

Using Teflon for pipes, liners, and wafer carriers ensures that the equipment does not corrode or contaminate the highly sensitive manufacturing process.

Key Applications in Electronics

These core properties translate directly into specific, high-value uses across the electronics industry, from individual components to the tools used to create them.

High-Frequency Wire and Cable Insulation

For applications like coaxial cables used in telecommunications and aerospace, signal integrity is paramount. Teflon's low dielectric constant ensures that the signal traveling through the wire is not dissipated or distorted.

Its high-temperature resistance also allows these cables to be used in demanding environments like engine bays or networking equipment closets.

Dielectric Material in PCBs

In high-frequency printed circuit boards (PCBs), the material between copper layers acts as an insulator. Using Teflon as this dielectric substrate minimizes signal loss between components.

This is essential for the performance of radar systems, satellite communications, and other high-performance radio frequency (RF) circuits.

Semiconductor Manufacturing

During the fabrication of microchips, silicon wafers must be moved and processed in an ultra-clean environment. Wafer carriers and other handling equipment coated with Teflon prevent wafers from sticking and resist damage from the aggressive chemicals used.

The chemical inertness of Teflon ensures purity throughout the manufacturing process, which is critical for achieving high yields of functional chips.

Understanding the Trade-offs

While Teflon offers superior performance, it is not the default choice for every application. Its advantages must be weighed against its practical limitations.

Higher Material Cost

Teflon is a premium material and is significantly more expensive than standard insulators like PVC or polyethylene. Its use is typically justified only in applications where its high performance is a strict requirement.

Processing Challenges

Compared to many conventional plastics, Teflon can be more difficult to mold and bond. This adds complexity and cost to the manufacturing process, requiring specialized techniques and equipment.

Mechanical Limitations

While durable, Teflon is a relatively soft material and can be susceptible to "creep" or cold flow under sustained mechanical load. In applications requiring high structural rigidity, it may need to be reinforced or replaced with a different engineering plastic.

Making the Right Choice for Your Goal

Selecting the appropriate material is a critical decision based on performance needs and budget constraints.

- If your primary focus is high-frequency performance: Teflon's low dielectric constant is the superior choice for PCBs and coaxial cables to preserve signal integrity and minimize loss.

- If your primary focus is operating in high-temperature environments: Its unmatched thermal stability ensures long-term reliability for wiring and components that run hot.

- If your primary focus is cost-sensitive mass production: You will likely need to explore alternative insulators, as Teflon's high performance commands a premium price.

Ultimately, choosing Teflon is a strategic decision for applications where electrical performance and environmental resilience cannot be compromised.

Summary Table:

| Property | Benefit in Electronics | Key Application |

|---|---|---|

| Superior Electrical Insulation | Minimizes signal loss, prevents interference | High-frequency PCBs, coaxial cables |

| Exceptional Thermal Stability | Maintains integrity in high-temperature environments | High-temperature wiring, engine bays |

| Unmatched Chemical Inertness | Resists harsh chemicals, prevents contamination | Semiconductor wafer carriers, pipes, liners |

Need high-performance PTFE components for your electronic application?

KINTEK specializes in manufacturing precision PTFE components—including seals, liners, labware, and custom parts—for the semiconductor, medical, laboratory, and industrial sectors. We ensure superior electrical insulation, thermal stability, and chemical resistance for demanding environments.

Whether you need prototypes or high-volume orders, our custom fabrication expertise delivers reliability where it matters most. Contact us today to discuss your project requirements!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support