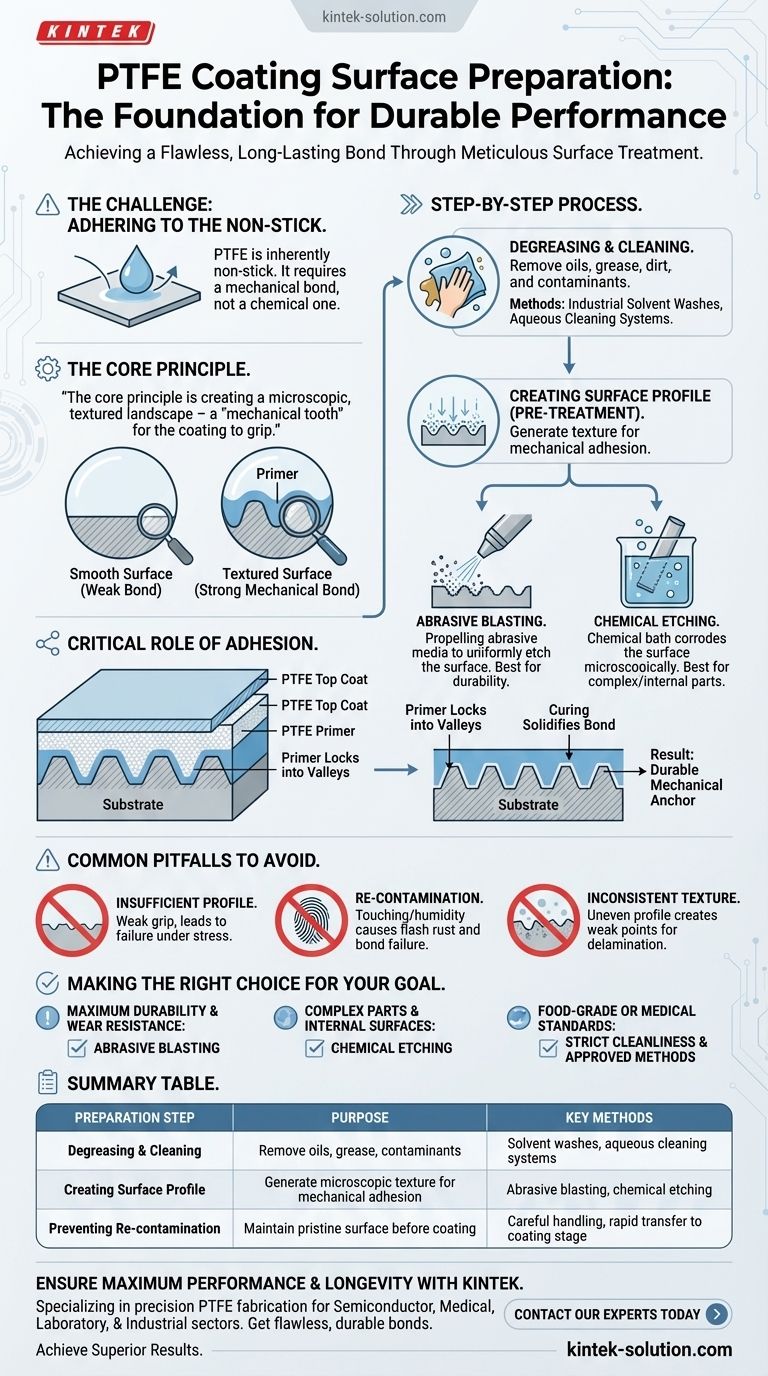

To properly prepare a surface for PTFE coating, you must first perform a thorough degreasing and cleaning. This is immediately followed by a pre-treatment process, most commonly abrasive blasting or chemical etching, which creates a textured surface profile essential for mechanical adhesion.

The core principle of PTFE surface preparation is not just to clean the substrate, but to create a microscopic, textured landscape. This "mechanical tooth" is what the coating physically grips onto, overcoming PTFE's natural non-stick properties to form a durable bond.

Why Meticulous Preparation is Non-Negotiable

Polytetrafluoroethylene (PTFE) is famous for its extremely low coefficient of friction—it is inherently non-stick. While this is its greatest strength in application, it is its greatest challenge during manufacturing. The coating will not properly adhere to a smooth, unprepared surface.

The Critical Role of Adhesion

Proper preparation creates a mechanical bond, not a chemical one. The process roughens the substrate, creating microscopic peaks and valleys.

The liquid PTFE primer flows into these valleys. During the curing (baking) process, it solidifies, locking itself firmly onto the substrate like millions of microscopic anchors.

Removing All Barriers to Contact

Any contaminant—such as oil, grease, rust, or old coatings—acts as a barrier layer. If these are not completely removed, the PTFE coating will bond to the contaminant instead of the substrate itself.

This results in a weak bond that is destined for premature failure, such as flaking, bubbling, or peeling.

The Standard Preparation Process

The application of a PTFE coating system is a multi-step process, but the foundation is always built on surface preparation.

Step 1: Degreasing and Cleaning

This is the mandatory first step. The goal is to remove all organic (oils, grease) and inorganic (dirt, dust) soils from the surface.

This is typically achieved using industrial-grade solvent washes or aqueous cleaning systems. The part must be perfectly clean before proceeding.

Step 2: Creating the Surface Profile

Once clean, the surface must be physically or chemically altered to create the necessary texture for adhesion.

Abrasive Blasting (or grit blasting) is the most common and effective method. It involves propelling abrasive media (like aluminum oxide) at high velocity against the substrate. This uniformly etches and roughens the surface, creating an ideal profile.

Chemical Etching is an alternative method where the part is submerged in a chemical bath that corrodes the surface on a microscopic level. This can be useful for delicate parts or complex internal geometries where blasting cannot reach.

Common Pitfalls to Avoid

The quality of the final coating is directly tied to the quality of the preparation. Cutting corners here will always compromise the result.

Insufficient Profile

If the surface is not roughened enough, the coating will have a weak grip. The bond will fail under minimal stress, especially in applications involving thermal cycling or physical impact.

Re-contamination After Preparation

A perfectly prepared surface is extremely vulnerable. Touching it with bare hands will transfer oils, and exposure to a humid environment can cause immediate "flash rust" on steel substrates.

The part must be moved to the coating stage as quickly as possible after preparation, and handled carefully to prevent any re-contamination.

Inconsistent Texture

An uneven blast or etch results in an inconsistent surface profile. This creates weak points across the surface where the coating is more likely to delaminate over time.

Making the Right Choice for Your Goal

The entire coating process involves preparation, applying a primer, applying the PTFE top coat, and finally, curing at high temperature. However, the preparation step dictates the ultimate performance.

- If your primary focus is maximum durability and wear resistance: A precisely controlled abrasive blast is essential to create a deep, uniform profile that provides the strongest possible mechanical anchor.

- If your primary focus is coating complex parts or internal surfaces: Chemical etching may be the only viable method to ensure every part of the substrate is properly prepared for adhesion.

- If your primary focus is meeting food-grade or medical standards: The process demands an unwavering commitment to cleanliness and using specific, approved coating systems and preparation methods to prevent any contamination.

Ultimately, remember that surface preparation is the foundation upon which the performance of any PTFE coating is built.

Summary Table:

| Preparation Step | Purpose | Key Methods |

|---|---|---|

| Degreasing & Cleaning | Remove oils, grease, and contaminants | Solvent washes, aqueous cleaning systems |

| Creating Surface Profile | Generate microscopic texture for mechanical adhesion | Abrasive blasting, chemical etching |

| Preventing Re-contamination | Maintain pristine surface before coating | Careful handling, rapid transfer to coating stage |

Ensure your PTFE-coated components deliver maximum performance and longevity. At KINTEK, we specialize in precision PTFE fabrication for the semiconductor, medical, laboratory, and industrial sectors. Our expertise in surface preparation and custom coating application ensures a flawless, durable bond for your seals, liners, and labware—from prototypes to high-volume orders. Contact our experts today to discuss your project requirements and achieve superior results.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What manufacturing capabilities are associated with PTFE parts? Unlock Precision with Expert Machining

- What are the key benefits of using PTFE in seals? Achieve Unmatched Reliability in Extreme Conditions

- Why should traditional lubricants not be used with PTFE-lined bearings? Avoid Premature Failure and High Friction

- What materials are used in spring energized Teflon seals? A Guide to PTFE Jackets & Metal Springs

- What are the main benefits of using PTFE liners? Achieve Unmatched Chemical and Thermal Resistance

- How does PTFE's thermal expansion and contraction affect its machining and application? Master Dimensional Stability

- What are the best practices for installing Teflon gland packing? Ensure a Reliable, Long-Lasting Seal

- What are the benefits of using custom Teflon parts for clients? Reduce Costs & Boost Reliability