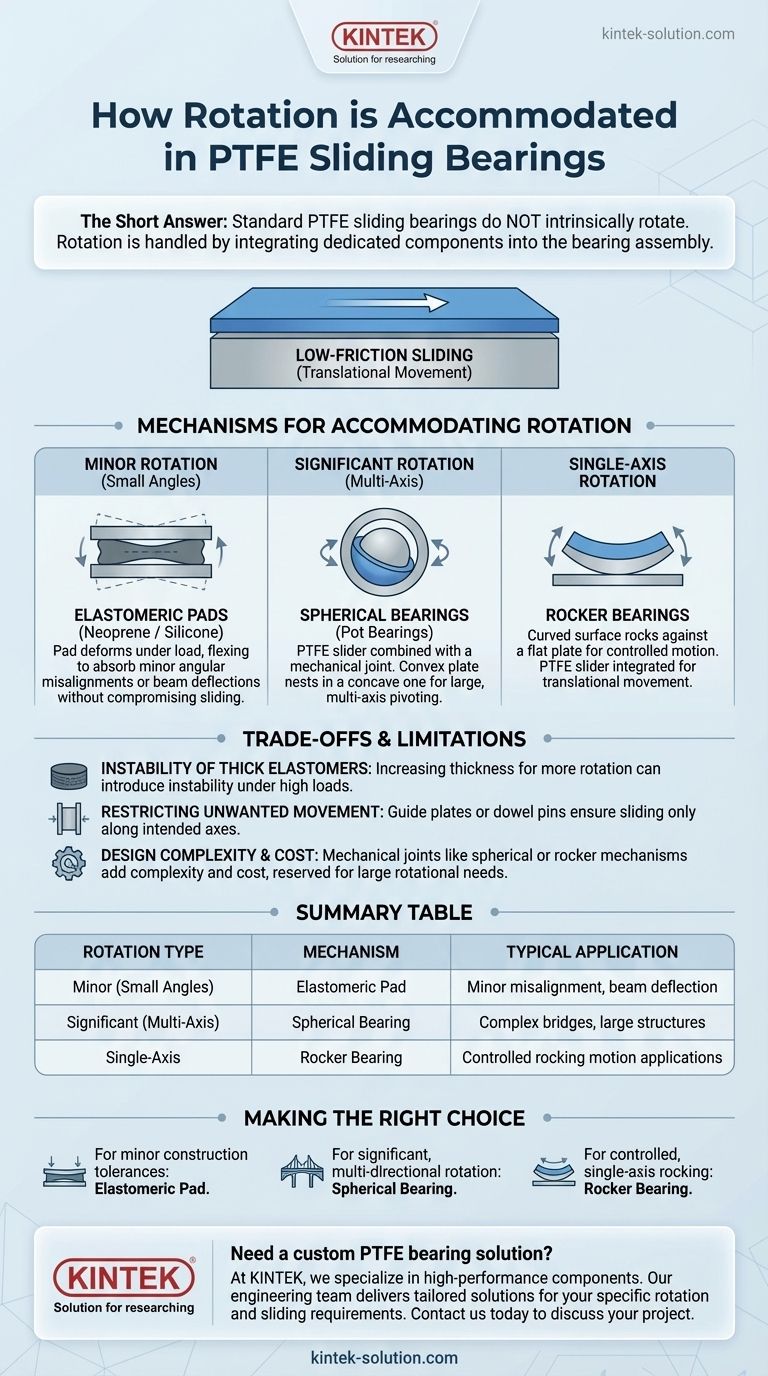

The short answer is that a standard PTFE sliding bearing does not intrinsically rotate; instead, rotation is accommodated by integrating other components into the bearing assembly. For minimal rotation caused by misalignment, a deformable elastomeric pad is used. For more significant rotational demands, the PTFE sliding component is combined with a dedicated mechanical bearing, such as a spherical or rocker bearing.

The core principle to understand is that PTFE's role is to provide a low-friction surface for linear sliding. To handle rotation, the bearing assembly must incorporate a separate, specialized mechanism—either a flexible material for small angles or a mechanical joint for larger ones.

The Purpose of PTFE in Structural Bearings

Designed for Low-Friction Sliding

The primary function of a PTFE sliding bearing is to manage translational movement. This is critical in large structures like bridges, pipelines, and buildings.

PTFE's exceptionally low coefficient of friction allows structural elements to slide past one another smoothly. This movement dissipates energy from sources like thermal expansion and contraction, seismic shifts, or differential forces.

Accommodating Multiple Forces

A complete bearing assembly is designed to handle a range of specified forces. These include vertical load (compression), longitudinal movement (sliding), and often lateral (sideways) movement.

Rotation is another critical design parameter that must be specified by the engineer and accounted for by the bearing manufacturer.

Mechanisms for Accommodating Rotation

For Minor Rotation: Elastomeric Pads

The most common method for handling small rotational angles (typically fractions of a degree) is to place an elastomeric pad, such as neoprene or silicone, within the bearing assembly.

This pad sits between the steel backing plates and deforms under load. Its ability to flex allows the bearing to absorb minor angular misalignments or deflections without compromising the sliding function of the PTFE surface.

For Significant Rotation: Spherical Bearings

When a structure requires larger, multi-axis rotation, a PTFE slider is often combined with a spherical bearing (also known as a pot bearing).

In this arrangement, a convex metal plate nests inside a concave one, allowing for significant angular pivoting. The PTFE sliding surface is then built on top of this rotational mechanism, creating a composite bearing that handles both sliding and high rotation.

For Single-Axis Rotation: Rocker Bearings

In applications where rotation occurs primarily along a single axis, a rocker bearing can be used in conjunction with a PTFE slider.

The rocker bearing consists of a curved surface that rocks against a flat plate, enabling a controlled rocking motion. The PTFE sliding plate is mounted on this assembly to provide the necessary translational movement, resulting in a "rocking-cum-sliding" function.

Understanding the Trade-offs and Limitations

The Instability of Thick Elastomers

While it may seem logical to use a thicker elastomeric pad to achieve more rotation, this approach has a significant drawback.

Increasing the thickness of the elastomer can introduce instability into the bearing, especially under high vertical loads. This is a critical safety and performance consideration that limits the rotational capacity of this design.

Restricting Unwanted Movement

Most PTFE bearing assemblies must only permit movement in specific directions. To prevent unwanted lateral or transverse motion, guide plates or dowel pins are incorporated.

These guides ensure the bearing slides only along the intended longitudinal axis while still allowing for the designed rotation via the elastomer or mechanical joint.

Design Complexity and Cost

The solution must match the need. An elastomeric pad is a simple and cost-effective solution for minor rotation.

Conversely, integrating spherical or rocker mechanisms adds significant complexity and cost to the design and manufacturing process. These are reserved for applications where large, predictable rotation is an essential structural requirement.

Making the Right Choice for Your Application

The selection of a rotational mechanism is dictated entirely by the structural demands of your specific project.

- If your primary focus is accommodating minor construction tolerances or slight beam deflection: A standard PTFE sliding bearing with an integrated elastomeric pad is the most efficient and appropriate solution.

- If your primary focus is managing significant, multi-directional rotation as seen in complex bridges or arenas: A composite assembly that combines a PTFE slider with a spherical bearing is required.

- If your primary focus is allowing a controlled, single-axis rocking motion: A PTFE slider integrated with a rocker bearing will provide the necessary degrees of freedom.

Ultimately, the key is to view the PTFE slider as one part of a system designed to manage all anticipated structural loads and movements.

Summary Table:

| Rotation Type | Mechanism | Typical Application |

|---|---|---|

| Minor (Small Angles) | Elastomeric Pad (Neoprene/Silicone) | Minor misalignment, beam deflection |

| Significant (Multi-Axis) | Spherical Bearing (Pot Bearing) | Complex bridges, large structures |

| Single-Axis | Rocker Bearing | Controlled rocking motion applications |

Need a PTFE bearing solution that perfectly accommodates your project's specific rotation and sliding requirements?

At KINTEK, we specialize in the custom fabrication of high-performance PTFE components, including seals, liners, and specialized bearing assemblies for the semiconductor, medical, laboratory, and industrial sectors. Our expertise ensures your bearing design manages all anticipated structural movements—from precise sliding to complex rotation—with reliability and precision.

We work with you from prototype to high-volume production to deliver a solution that meets your exact specifications for load, movement, and environmental conditions.

Contact our engineering team today to discuss your project requirements and receive a tailored solution.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability