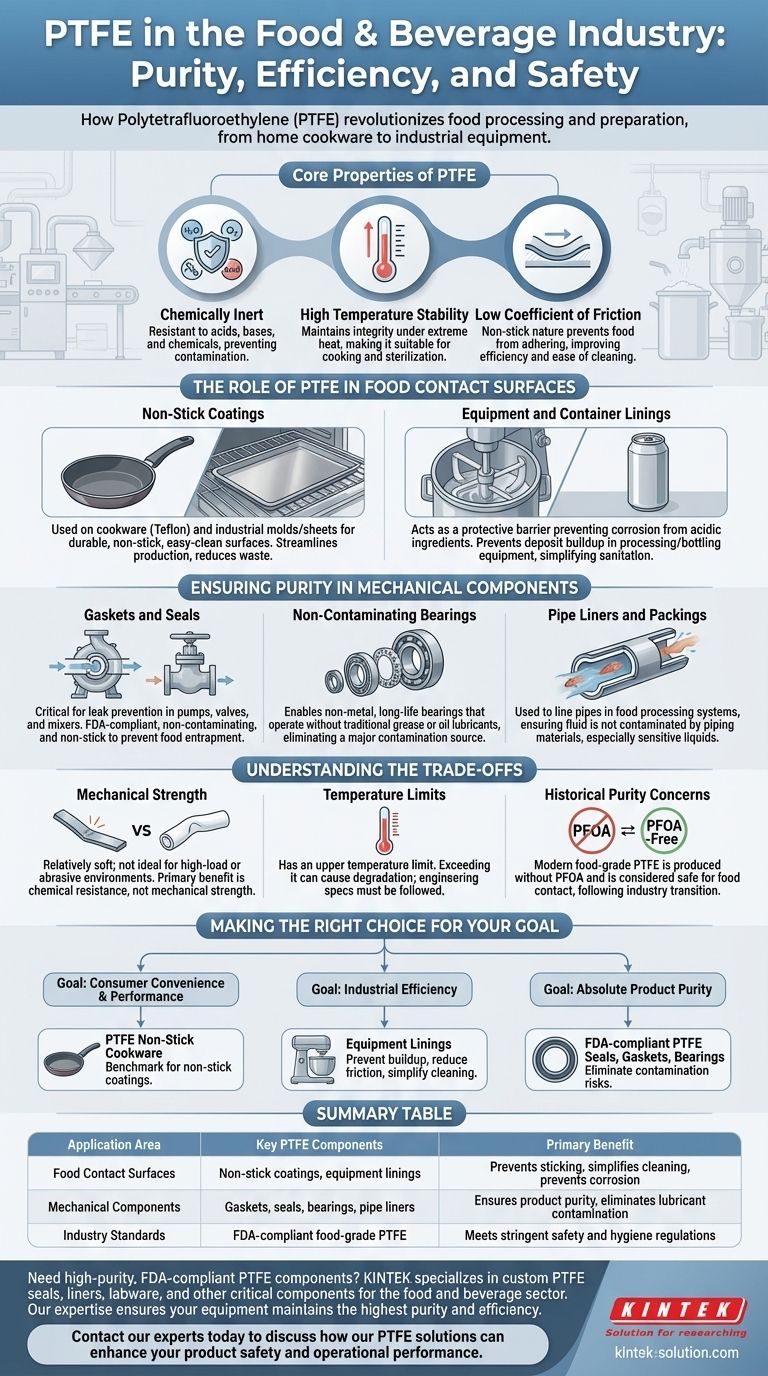

In the food and beverage industry, Polytetrafluoroethylene (PTFE) is a uniquely versatile material used for everything from the non-stick coatings on consumer cookware to critical components in industrial processing equipment. Its applications extend far beyond the kitchen, playing a vital role in ensuring product purity, operational efficiency, and safety compliance in large-scale production.

The core reason PTFE is so prevalent is its rare combination of three key properties: it is almost completely chemically inert, it maintains stability at high temperatures, and it has an extremely low coefficient of friction. This trifecta makes it the ideal material for preventing contamination and improving efficiency wherever food products are handled.

The Role of PTFE in Food Contact Surfaces

One of the most widely recognized uses of PTFE is in direct contact with food, where its non-stick and non-reactive properties are paramount.

Non-Stick Coatings

PTFE, commonly known by the trade name Teflon, is applied as a coating to consumer pots and pans. This creates a durable, heat-resistant, and easy-to-clean surface that prevents food from adhering during cooking.

This same principle is applied to industrial baking sheets, molds, and other food preparation appliances, streamlining production and reducing waste.

Equipment and Container Linings

The interiors of many food and beverage containers are coated with PTFE. This lining acts as a protective barrier, preventing corrosion from acidic ingredients or oxidizing agents that could otherwise leach materials into the product.

In processing and bottling equipment, a PTFE coating prevents the buildup of deposits. This not only maintains operational efficiency but also simplifies the cleaning and sanitation cycles required to meet hygiene standards.

Ensuring Purity in Mechanical Components

Beyond simple coatings, PTFE is engineered into essential mechanical parts where preventing contamination is a non-negotiable requirement.

Gaskets and Seals

PTFE gaskets and seals are critical components in pumps, valves, mixers, and heat exchangers. Their job is to prevent leaks without reacting with or contaminating the product passing through the system.

Because food-grade PTFE is compliant with FDA standards, it is a trusted choice for creating tight seals in dairy, beverage, and other sanitary processing lines. Its non-stick surface also prevents food particles from getting trapped, which is essential for hygienic processing.

Non-Contaminating Bearings

In equipment like industrial mixers, PTFE is used to create non-metal bearings. These components provide long life and low friction without requiring traditional grease or oil lubricants.

This eliminates a major potential source of contamination, ensuring that only the intended ingredients are present in the final product.

Pipe Liners and Packings

PTFE is used to line pipes and create packing seals in food processing systems. This ensures that the liquids flowing through the equipment are not contaminated by the piping material itself. This is especially important when handling sensitive or reactive fluids.

Understanding the Trade-offs

While PTFE is exceptionally useful, it's important to understand its specific limitations to apply it correctly.

Mechanical Strength

PTFE is a relatively soft material. While durable in its intended applications, it is not ideal for high-load or high-abrasion environments where the strength of metal is required. Its primary benefits are chemical, not mechanical.

Temperature Limits

Although known for high-temperature resistance, PTFE does have an upper limit. Exceeding its maximum service temperature can cause it to degrade, so engineering specifications must be carefully followed in industrial settings.

Historical Purity Concerns

Early manufacturing processes for PTFE used a processing aid called PFOA, which raised health concerns. However, the industry has since transitioned to new technologies, and modern, food-grade PTFE is produced without PFOA and is considered safe for food contact applications.

Making the Right Choice for Your Goal

Selecting PTFE is about leveraging its specific strengths to solve a clear problem, whether in a consumer product or an industrial facility.

- If your primary focus is consumer convenience and performance: PTFE provides the benchmark for non-stick cookware coatings, valued for heat resistance and ease of cleaning.

- If your primary focus is industrial efficiency: Use PTFE for equipment linings to prevent deposit buildup, reduce friction, and simplify mandatory cleaning cycles.

- If your primary focus is absolute product purity: Select FDA-compliant PTFE for seals, gaskets, and bearings to eliminate the risk of contamination from chemical reactions or lubricants.

Ultimately, PTFE's unique combination of properties makes it an indispensable material for maintaining both the quality and safety of modern food production.

Summary Table:

| Application Area | Key PTFE Components | Primary Benefit |

|---|---|---|

| Food Contact Surfaces | Non-stick coatings, equipment linings | Prevents sticking, simplifies cleaning, prevents corrosion |

| Mechanical Components | Gaskets, seals, bearings, pipe liners | Ensures product purity, eliminates lubricant contamination |

| Industry Standards | FDA-compliant food-grade PTFE | Meets stringent safety and hygiene regulations |

Need high-purity, FDA-compliant PTFE components for your food and beverage operation?

KINTEK specializes in manufacturing custom PTFE seals, liners, labware, and other critical components for the semiconductor, medical, laboratory, and industrial sectors. Our expertise in precision production ensures your equipment maintains the highest standards of purity and efficiency, from prototype to high-volume orders.

Contact our experts today to discuss how our PTFE solutions can enhance your product safety and operational performance.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

People Also Ask

- What are some common applications of machined PTFE? Leverage its Unique Properties for Demanding Applications

- What is PTFE commonly known as and what are its unique properties? Unlock Unmatched Chemical & Thermal Resistance

- What are the material advantages of machining Teflon? Unlock Unmatched Chemical & Thermal Resistance

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What are the key benefits of PTFE in custom fabrication? Unlock Performance in Extreme Conditions