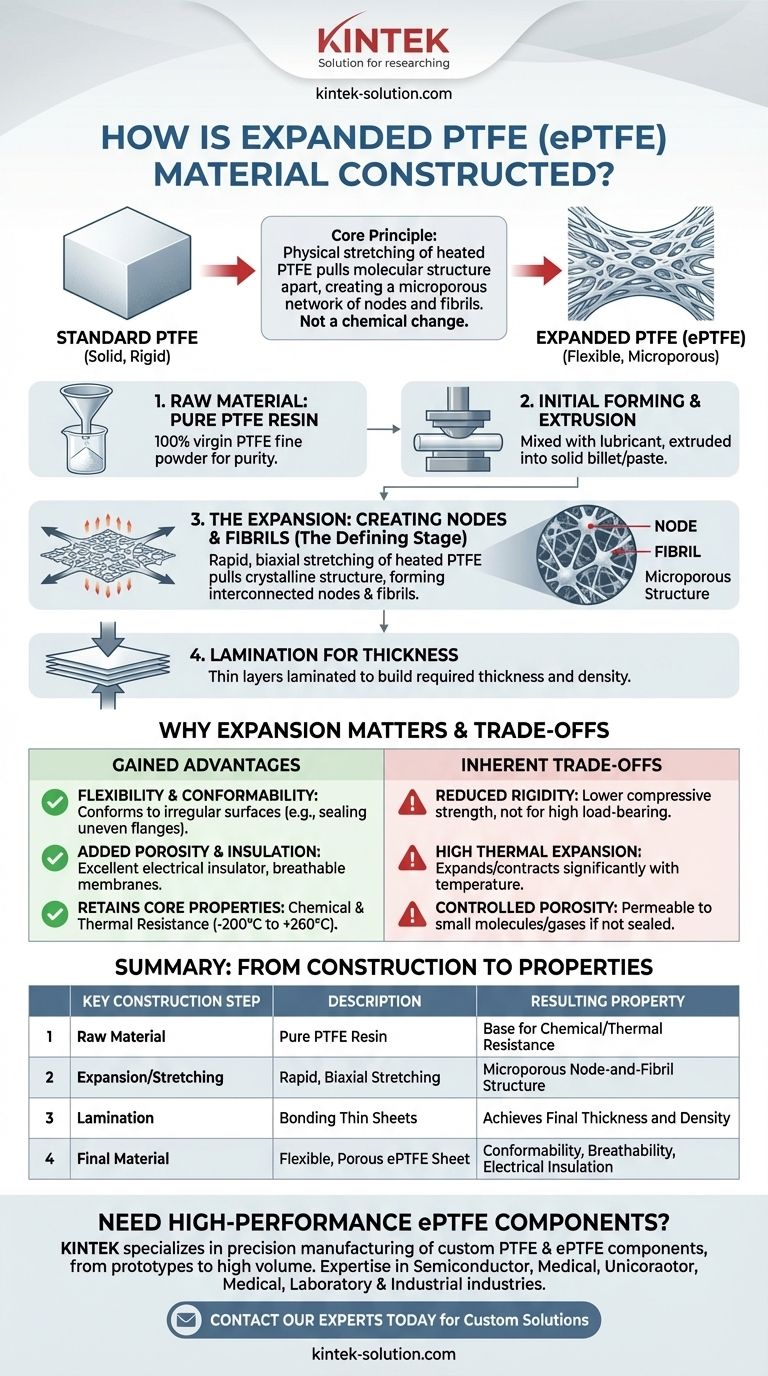

At its core, Expanded PTFE (ePTFE) is constructed by physically stretching standard Polytetrafluoroethylene (PTFE) under specific conditions. This expansion process transforms the solid material by pulling its molecular structure apart, creating a unique, microporous network of strong fibers and interconnected pores. This is not a chemical change but a mechanical one that unlocks a new set of physical properties while retaining PTFE's renowned chemical and thermal resistance.

The crucial takeaway is that the manufacturing process—specifically, the rapid, controlled stretching of PTFE—is what gives ePTFE its defining characteristics. This expansion converts a rigid polymer into a flexible, porous, and remarkably strong material suitable for applications where standard PTFE would fail.

From Raw Material to Microporous Structure

Understanding the journey from a simple resin to a high-performance material reveals why ePTFE is so versatile. The process is a masterpiece of polymer engineering, focused on creating a specific physical structure.

The Starting Point: Pure PTFE Resin

The process begins with 100% virgin PTFE. This raw material, often a special fine powder, is selected for its purity and molecular characteristics, which are critical for a successful expansion.

Initial Forming and Extrusion

The PTFE powder is mixed with a lubricant and extruded to form a basic shape, like a billet or paste. This step consolidates the raw material into a solid, workable form that is ready for the critical expansion phase.

The Expansion Step: Creating Nodes and Fibrils

This is the defining stage. The extruded PTFE is heated and then stretched rapidly and biaxially (in two directions). This high-speed stretching pulls the crystalline structure of the PTFE apart, forming a highly fibrous web of interconnected nodes and thin fibrils.

The result is a material that is mostly empty space, or porosity, but with an incredibly strong underlying structure. This microporous composition is what gives ePTFE its unique properties.

Lamination for Required Thickness

For certain applications like gasketing, the process doesn't end with a single sheet. Thin layers of this newly created ePTFE sheeting are laminated together to build up the final product to the required thickness and density.

Why the Expansion Process Matters

The physical transformation of PTFE into ePTFE is what unlocks its most valuable features. It inherits the best qualities of its parent material while gaining new mechanical advantages.

Retaining Core PTFE Properties

Even after the dramatic stretching process, ePTFE retains all the remarkable chemical and thermal properties of standard PTFE. This includes its extreme chemical resistance and its ability to withstand a wide temperature range (typically -200°C to +260°C).

Gaining Flexibility and Conformability

Unlike rigid, machined PTFE, the microporous structure of ePTFE is exceptionally flexible and elastic. This allows it to conform to irregular shapes, making it an ideal material for sealing uneven flanges without the need for custom-cut gaskets.

Adding Porosity and Insulation

The network of pores created during expansion makes the material an excellent electrical insulator, as the trapped air enhances its dielectric properties. This same porosity, when controlled, can also be engineered to allow vapor to pass through while blocking liquids.

Understanding the Trade-offs

While the expansion process creates many advantages, it's important to recognize the inherent trade-offs that come with altering the material's fundamental structure.

Reduced Rigidity

The porous, fibrous nature of ePTFE means it has a relatively lower rigidity and compressive strength compared to a solid, machined PTFE part. It is designed to be soft and conformable, not for high load-bearing applications.

High Thermal Expansion

Like its parent material, ePTFE has a high coefficient of thermal expansion. This means it will expand and contract significantly with temperature changes, a factor that must be accounted for in precision engineering designs.

Controlled by Porosity

The performance of an ePTFE component is directly tied to the size and distribution of its pores. This characteristic is an advantage when used for filtration or venting but can be a limitation if absolute impermeability to very small molecules or gases is required.

Making the Right Choice for Your Application

Selecting the right material depends entirely on the demands of your specific challenge. The construction of ePTFE directly dictates where it will excel.

- If your primary focus is sealing irregular surfaces: ePTFE's flexibility and conformability, derived directly from the expansion process, make it the superior choice.

- If your primary focus is electrical insulation or breathable membranes: The microporous structure created during stretching provides the exact properties needed for these applications.

- If your primary focus is high rigidity or load-bearing strength: A solid, machined component made from standard PTFE will likely be a more suitable and durable option.

By understanding that ePTFE is PTFE that has been mechanically expanded, you can confidently leverage its unique combination of chemical resilience and structural flexibility.

Summary Table:

| Key Construction Step | Description | Resulting Property |

|---|---|---|

| Raw Material | Pure, virgin PTFE fine powder resin. | Base for chemical/thermal resistance. |

| Expansion/Stretching | Rapid, biaxial stretching of heated PTFE. | Creates microporous node-and-fibril structure. |

| Lamination | Bonding thin ePTFE sheets together. | Achieves required final thickness and density. |

| Final Material | Flexible, porous ePTFE sheet or component. | Conformability, breathability, and electrical insulation. |

Need High-Performance ePTFE Components for Your Project?

At KINTEK, we specialize in the precision manufacturing of PTFE and Expanded PTFE (ePTFE) components. Our expertise in custom fabrication—from prototypes to high-volume production—ensures you get the exact material properties your application demands.

We serve specialized industries where material performance is critical:

- Semiconductor: For ultra-pure, chemical-resistant seals and liners.

- Medical: For biocompatible, breathable membranes and gaskets.

- Laboratory & Industrial: For flexible, durable seals and insulation.

Let us help you leverage the unique benefits of ePTFE.

Contact our experts today to discuss your specific requirements and get a custom solution quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

People Also Ask

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability