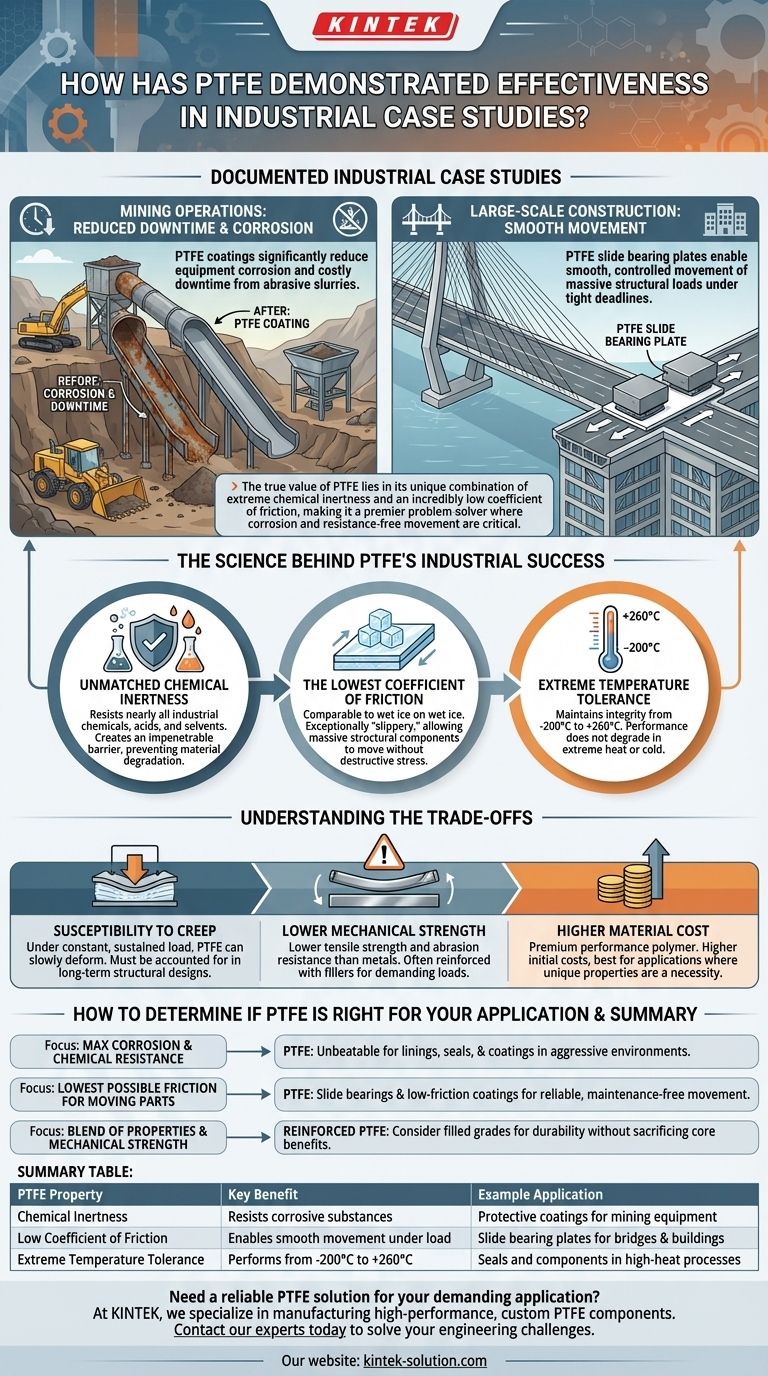

In documented industrial case studies, Polytetrafluoroethylene (PTFE) has proven highly effective in solving critical challenges in harsh environments. For instance, in mining operations, PTFE coatings have significantly reduced equipment corrosion and costly downtime, while in large-scale construction, PTFE slide bearing plates have enabled the smooth, controlled movement of massive structural loads under tight project deadlines.

The true value of PTFE in industrial settings lies in its unique combination of extreme chemical inertness and an incredibly low coefficient of friction, making it a premier problem-solver where corrosion and resistance-free movement are critical.

The Science Behind PTFE's Industrial Success

To understand why PTFE is so frequently specified in demanding applications, we must look at its fundamental material properties. These characteristics are not just theoretical; they directly translate to tangible performance benefits.

Unmatched Chemical Inertness

PTFE is one of the most non-reactive substances known. It resists nearly all industrial chemicals, acids, and solvents.

This property is the reason it excels as a protective coating in sectors like mining, where equipment is constantly exposed to corrosive slurries and chemicals. It creates an impenetrable barrier, preventing material degradation.

The Lowest Coefficient of Friction

PTFE has one of the lowest coefficients of friction of any solid material, comparable to wet ice on wet ice. This means it is exceptionally "slippery."

This is the key principle behind its use in slide bearing plates. It allows massive structural components, like bridge decks or large buildings, to move smoothly during thermal expansion and contraction without generating destructive stress.

Extreme Temperature Tolerance

Beyond its other properties, PTFE maintains its integrity across a vast temperature range, typically from -200°C to +260°C (-328°F to +500°F).

This thermal stability ensures its performance does not degrade in environments with extreme heat or cold, a common variable in many industrial processes.

Practical Applications in Demanding Sectors

The theoretical benefits of PTFE are best understood through its real-world impact. The case studies from mining and construction highlight how its properties solve distinct, high-stakes problems.

Reducing Downtime in Mining

In the mining industry, equipment failure is a primary cause of lost productivity. Abrasive and corrosive materials rapidly wear down metal components.

By applying PTFE coatings to chutes, hoppers, and processing equipment, operators protect the underlying metal. This extends the service life of the machinery, drastically cutting down on maintenance schedules and unexpected, costly downtime.

Ensuring Stability in Construction

Large modern structures are not static; they must be designed to move. Temperature fluctuations, wind, and seismic activity cause expansion, contraction, and shifting.

PTFE slide bearing plates are placed at critical structural junctions to accommodate this movement. Their low-friction surface allows heavy segments to slide past one another with minimal resistance, preserving the building's or bridge's structural integrity over decades.

Understanding the Trade-offs

While highly effective, PTFE is not a universal solution. An objective assessment requires acknowledging its limitations.

Susceptibility to Creep

Under a constant, sustained load, PTFE can slowly deform over time. This phenomenon, known as "creep," must be accounted for in long-term structural designs.

Lower Mechanical Strength

Compared to metals, PTFE has relatively low tensile strength and abrasion resistance. For this reason, it is often reinforced with fillers like glass fiber or carbon to enhance its mechanical properties for more demanding load-bearing roles.

Higher Material Cost

PTFE is a premium performance polymer. Its initial material and processing costs are higher than many conventional plastics and materials, making it best suited for applications where its unique properties are a necessity, not a preference.

How to Determine if PTFE is Right for Your Application

Choosing the correct material depends entirely on the primary challenge you need to solve.

- If your primary focus is maximum corrosion and chemical resistance: PTFE is an almost unbeatable choice for linings, seals, and coatings exposed to aggressive substances.

- If your primary focus is the lowest possible friction for moving parts: PTFE slide bearings or low-friction coatings offer reliable, maintenance-free movement under heavy loads.

- If your primary focus is a blend of properties including mechanical strength: Consider a reinforced or filled grade of PTFE to achieve the necessary durability without sacrificing its core benefits.

Ultimately, understanding PTFE's core strengths allows you to apply it with precision to solve some of industry's most demanding engineering challenges.

Summary Table:

| PTFE Property | Key Benefit | Example Application |

|---|---|---|

| Chemical Inertness | Resists corrosive substances | Protective coatings for mining equipment |

| Low Coefficient of Friction | Enables smooth movement under load | Slide bearing plates for bridges & buildings |

| Extreme Temperature Tolerance | Performs from -200°C to +260°C | Seals and components in high-heat processes |

Need a reliable PTFE solution for your demanding application?

At KINTEK, we specialize in manufacturing high-performance, custom PTFE components—including seals, liners, labware, and more—for the semiconductor, medical, laboratory, and industrial sectors. Whether you require prototypes or high-volume production, our precision manufacturing ensures your components meet the highest standards for chemical resistance, low friction, and durability.

Contact our experts today to discuss how our PTFE expertise can solve your specific engineering challenges and enhance your operational efficiency.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

People Also Ask

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability