At its core, the non-stick surface of a Polytetrafluoroethylene (PTFE) flange gasket dramatically simplifies installation and maintenance by preventing it from bonding to the flange faces. Unlike other materials that can adhere over time due to heat and pressure, a PTFE gasket can be removed cleanly and quickly, drastically reducing the labor and risk associated with gasket replacement.

The primary value of PTFE's non-stick property is not just convenience, but direct cost savings. It translates to significantly reduced maintenance hours and, crucially, minimizes the risk of damaging expensive flange surfaces during removal.

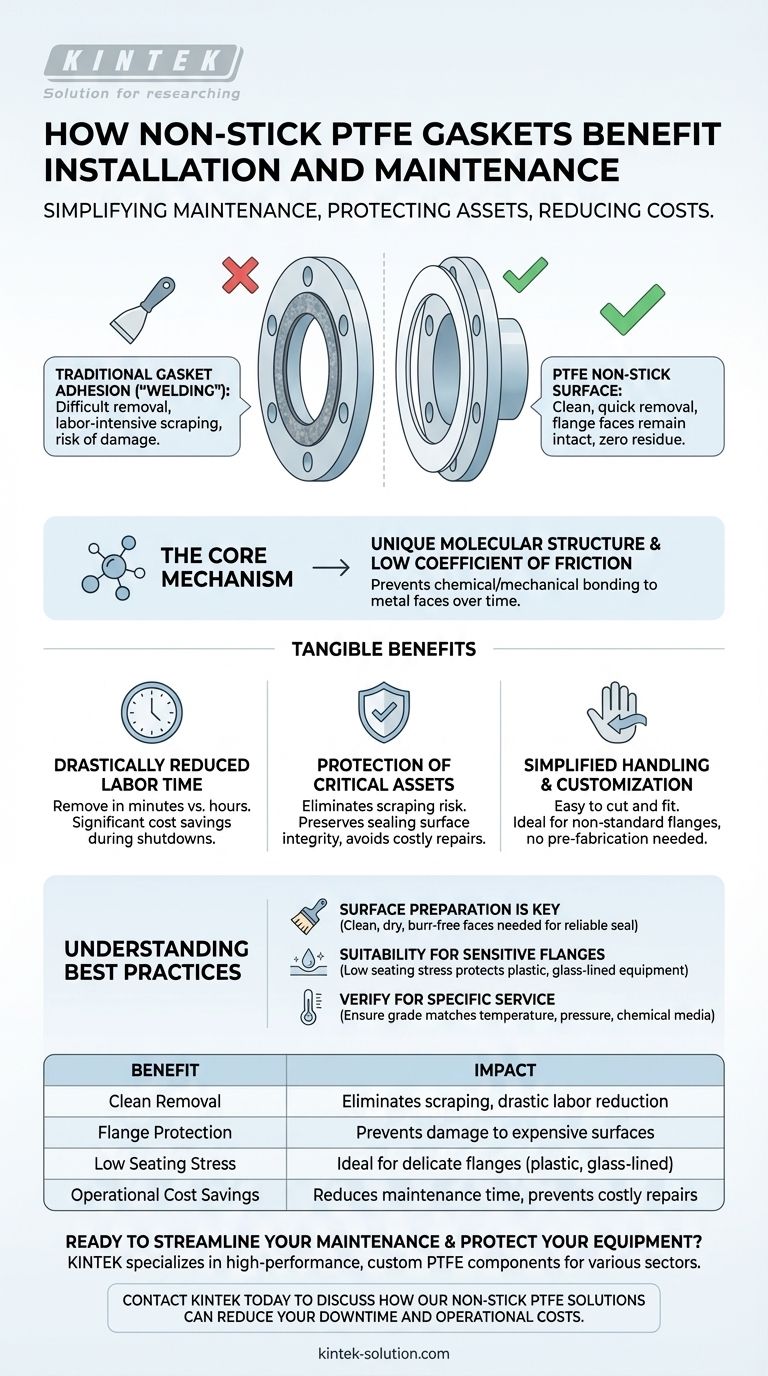

The Core Mechanism: Preventing Gasket Adhesion

The "non-stick" quality of PTFE is a result of its unique molecular structure, which creates a very low coefficient of friction. This property is fundamental to its performance in industrial sealing.

What "Non-Stick" Means for a Flange

Over time, gaskets made from other materials can chemically or mechanically bond to the metal flange faces they are compressed between. This process, often called gasket adhesion or "welding," makes removal extremely difficult.

This adhesion forces maintenance technicians to use scrapers, chisels, or abrasive tools to remove the old gasket material piece by piece.

The PTFE Advantage in Disassembly

A PTFE gasket’s non-stick surface resists this bonding process. When a joint is disassembled, the gasket lifts away cleanly from both mating surfaces.

This leaves the flange faces clean and ready for the new gasket, eliminating the time-consuming and labor-intensive scraping process. This simple feature is a game-changer for maintenance efficiency.

Tangible Benefits for Installation and Maintenance

The prevention of adhesion creates a cascade of benefits that directly impact operational uptime, cost, and safety.

Drastically Reduced Labor Time

The single greatest benefit is the reduction in time required for gasket replacement. Removing a bonded gasket can take hours, whereas a PTFE gasket can often be removed in minutes.

This reduction in labor time per flange translates into significant cost savings, especially during large-scale plant shutdowns or turnarounds where hundreds of gaskets may be replaced.

Protection of Critical Assets

Aggressively scraping a flange face to remove a bonded gasket creates a high risk of scratching, gouging, or otherwise damaging the sealing surface.

A damaged flange face will not seal properly, leading to dangerous leaks or requiring costly and time-consuming in-place machining or component replacement. PTFE's clean removal preserves the integrity of these critical assets.

Simplified Handling and Customization

PTFE and its expanded form (ePTFE) are easy to handle and cut. Gaskets can be quickly customized to the exact size needed, simplifying the initial installation process.

This adaptability is especially useful for sealing irregular or non-standard flanges, ensuring a proper fit without the need for pre-fabricated specialty gaskets.

Understanding the Trade-offs and Best Practices

While highly advantageous, using PTFE gaskets effectively requires understanding their operational context and proper installation procedures.

The Importance of Surface Preparation

A non-stick surface is not a substitute for proper flange preparation. To achieve a reliable seal, the flange faces must be clean, dry, and free of burrs, deep scratches, or any old gasket residue.

Proper preparation ensures the gasket can conform perfectly to the surfaces and be compressed evenly, which is essential for seal integrity.

Suitability for Sensitive Flanges

The low seating stress required for PTFE gaskets makes them an excellent choice for more delicate flange materials, such as plastic, rubber, or enamel-lined equipment.

These materials are easily damaged by the high compression forces needed for harder gasket types. PTFE provides a reliable seal without risking damage to the flange.

Verify for Your Specific Service

PTFE provides a reliable seal across significant pressure variations, which enhances plant safety. However, like any material, it has specific temperature and pressure limitations.

Always verify that the specific grade of PTFE gasket you select is rated for the temperature, pressure, and chemical media of your application to ensure long-term, safe performance.

Making the Right Choice for Your Goal

Selecting a PTFE gasket is a strategic decision to improve maintenance efficiency and protect equipment.

- If your primary focus is minimizing maintenance downtime: PTFE is an unparalleled choice, as its easy removal directly cuts down on labor hours per flange.

- If your primary focus is protecting sensitive or delicate flanges: PTFE's low required seating stress provides an effective seal without damaging plastic, glass-lined, or other fragile surfaces.

- If your primary focus is long-term operational cost: The combination of long service life, reduced labor costs, and prevention of flange damage makes PTFE a highly economical solution over the equipment's lifecycle.

Ultimately, choosing a gasket with a non-stick surface is an investment in faster, safer, and more cost-effective maintenance operations.

Summary Table:

| Benefit | Impact |

|---|---|

| Clean Removal | Eliminates scraping, drastically reduces labor hours. |

| Flange Protection | Prevents damage to expensive sealing surfaces. |

| Low Seating Stress | Ideal for delicate flanges (plastic, glass-lined). |

| Operational Cost Savings | Reduces maintenance time and prevents costly repairs. |

Ready to streamline your maintenance and protect your equipment?

KINTEK specializes in manufacturing high-performance, custom PTFE components—including seals, gaskets, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors. Our precision production ensures a perfect fit and reliable performance, from prototypes to high-volume orders.

Contact KINTEK today to discuss how our non-stick PTFE solutions can reduce your downtime and operational costs.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

People Also Ask

- What finishing techniques are effective for machined Teflon parts? Achieve Functional Performance and Dimensional Stability

- What fabrication services are available for PTFE? Shearing, Stamping, Laser Cutting, Molding & Machining

- What design considerations are important for custom PTFE parts? Design for Performance & Reliability

- What are the main applications of PTFE type Teflon? Unlock Its Versatility for Your Industry

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications