In gasket applications, the non-stick property of PTFE (Polytetrafluoroethylene) delivers two primary benefits: it ensures superior hygiene by preventing material buildup and it enhances mechanical integrity by reducing friction and wear between sealing surfaces. This dual advantage makes it a critical material in both sanitary and demanding industrial environments.

PTFE's non-stick nature is more than a convenience; it is a fundamental characteristic that translates directly into lower maintenance costs, enhanced system purity, and improved operational reliability for gasketed joints.

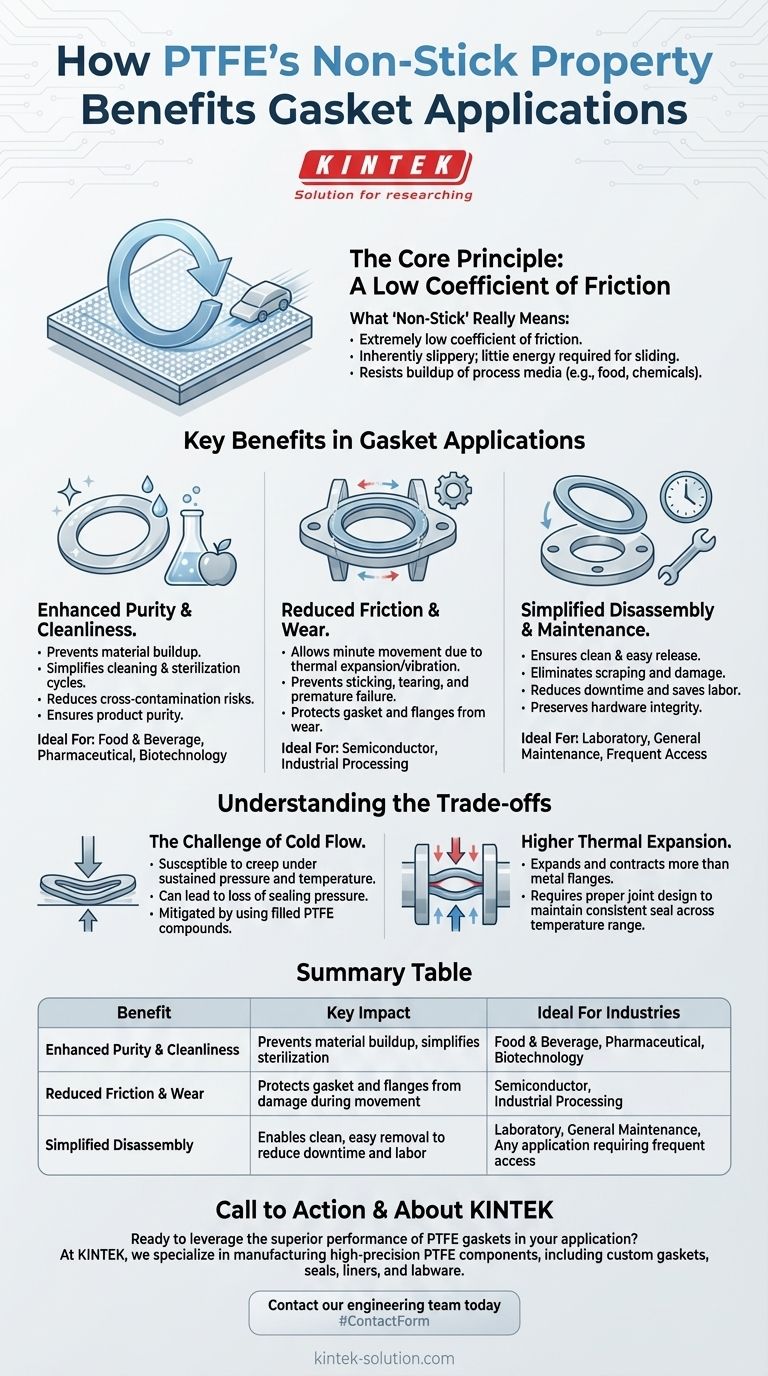

The Core Principle: A Low Coefficient of Friction

What "Non-Stick" Really Means

The term "non-stick" is the practical description of a material's extremely low coefficient of friction. PTFE has one of the lowest friction coefficients of any known solid material.

This inherent slipperiness means that very little energy is required for another object to slide across its surface.

The Practical Impact on Sealing

Because other substances cannot easily adhere to it, a PTFE gasket resists the buildup of process media. This applies to everything from sticky food products to industrial chemicals.

This property ensures the gasket's surface remains clean and that the seal's performance is not compromised by contamination or blockages.

Key Benefits in Gasket Applications

Benefit 1: Enhanced Purity and Cleanliness

In industries like food processing, pharmaceuticals, and biotechnology, hygiene is non-negotiable. PTFE gaskets excel here.

Their non-stick surface prevents process media from clinging to the gasket, which drastically simplifies cleaning and sterilization cycles. This reduces the risk of cross-contamination between batches and ensures product purity.

Benefit 2: Reduced Friction and Wear

In mechanical applications, gaskets are often compressed between two flange faces that may experience slight movement due to thermal expansion, pressure changes, or vibration.

A traditional gasket might stick to these faces, leading to tearing, degradation, and premature failure. PTFE's low-friction surface allows for this minute movement without causing damage to the gasket or the flange, extending the service life of the entire joint.

Benefit 3: Simplified Disassembly and Maintenance

One of the most common maintenance frustrations is a gasket that has become bonded to the flange surfaces. This requires time-consuming scraping that can damage the flange and introduce debris into the system.

PTFE's non-stick property ensures clean and easy release during disassembly. The gasket can be removed cleanly, saving significant labor, reducing downtime, and preserving the integrity of expensive hardware.

Understanding the Trade-offs

The Challenge of Cold Flow

While powerful, PTFE is not without its limitations. Its most notable trade-off in gasket applications is its susceptibility to creep, or "cold flow."

Under sustained pressure and temperature, pure PTFE can slowly deform, which may lead to a loss of bolt torque and sealing pressure over time. This is often mitigated by using filled PTFE compounds, which add materials like glass or carbon to improve creep resistance.

Higher Thermal Expansion

PTFE expands and contracts with temperature changes more than the metal flanges it typically seals. This difference in thermal expansion must be accounted for in the joint design to maintain a consistent seal across a wide operating temperature range.

Making the Right Choice for Your System

Selecting the right gasket material requires aligning its properties with your primary operational goal.

- If your primary focus is hygiene and cleanability: PTFE's non-stick surface is invaluable for preventing product buildup and simplifying critical sanitation protocols.

- If your primary focus is equipment longevity: The low-friction nature of PTFE protects both the gasket and the mating flange surfaces from wear, especially in systems with vibration or thermal cycling.

- If your primary focus is minimizing maintenance downtime: A PTFE gasket guarantees clean and easy removal, dramatically speeding up repair and replacement cycles.

Ultimately, leveraging PTFE's non-stick property is about designing a cleaner, more durable, and more efficient sealing system.

Summary Table:

| Benefit | Key Impact | Ideal For Industries |

|---|---|---|

| Enhanced Purity & Cleanliness | Prevents material buildup, simplifies sterilization | Food & Beverage, Pharmaceutical, Biotechnology |

| Reduced Friction & Wear | Protects gasket and flanges from damage during movement | Semiconductor, Industrial Processing |

| Simplified Disassembly | Enables clean, easy removal to reduce downtime and labor | Laboratory, General Maintenance, Any application requiring frequent access |

| Trade-off: Cold Flow | Can deform under sustained pressure; often mitigated with filled compounds | - |

| Trade-off: Thermal Expansion | Expands/contracts more than metal flanges; requires proper joint design | - |

Ready to leverage the superior performance of PTFE gaskets in your application?

At KINTEK, we specialize in manufacturing high-precision PTFE components, including custom gaskets, seals, liners, and labware. Whether you need a prototype for testing or high-volume production for semiconductor, medical, laboratory, or industrial use, our expertise ensures a solution that maximizes cleanliness, durability, and operational efficiency.

Contact our engineering team today to discuss your specific requirements and receive a custom quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

People Also Ask

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments