In short, the low spring rate of PTFE allows bellows to absorb vibration, shock, and misalignment with minimal force. This makes them exceptionally good at protecting connected equipment, especially fragile components like glass or graphite, from mechanical stress that could otherwise cause damage.

The core challenge in many piping systems is not just connecting two points, but decoupling them from each other's mechanical stresses. PTFE's low spring rate is the key feature that allows a bellows to act as a nearly perfect isolator, absorbing movement and vibration instead of transmitting it.

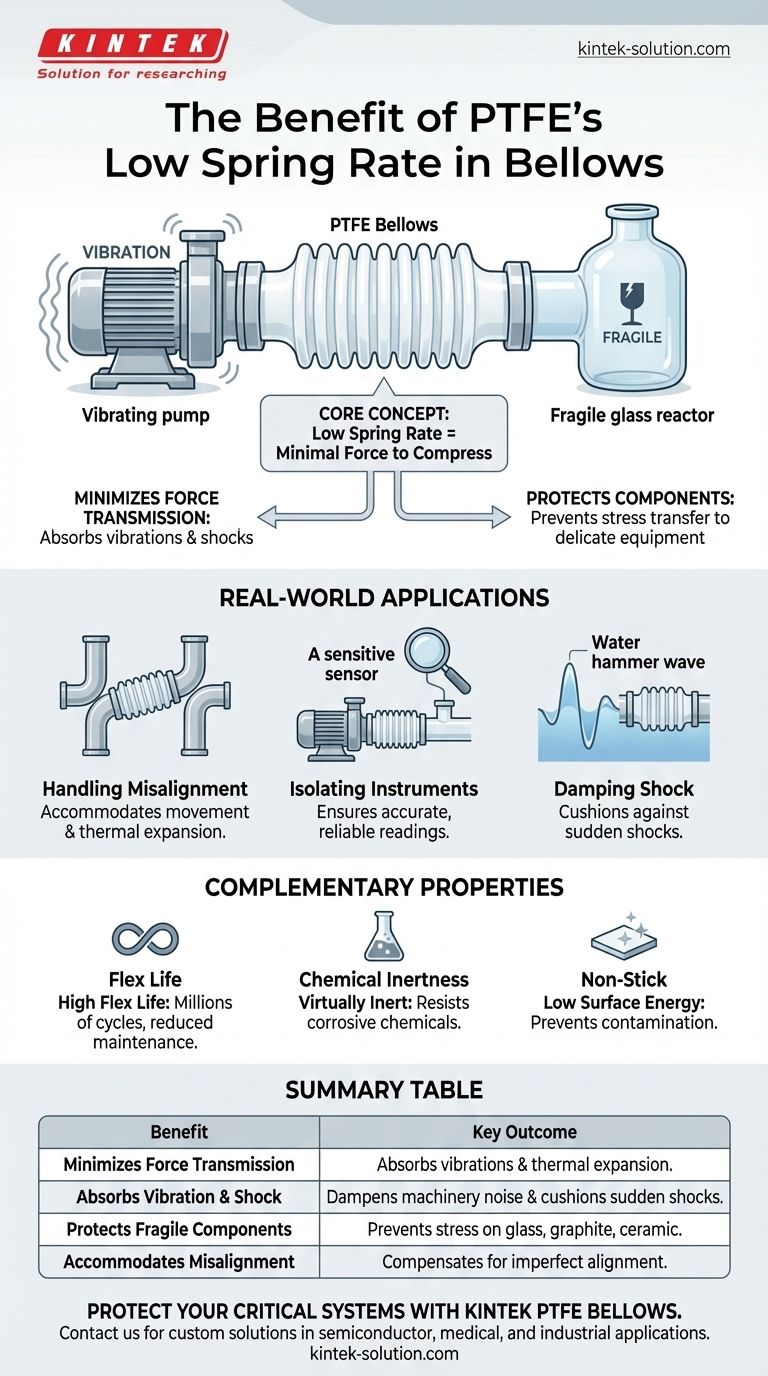

The Core Function of a Low Spring Rate

A material's "spring rate" defines how much force is needed to compress or extend it by a certain distance. A low spring rate means very little force is required. This property is fundamental to the protective function of PTFE bellows.

Minimizing Force Transmission

A bellows with a high spring rate would act like a rigid pipe, transferring nearly all forces from one end to the other.

PTFE's low spring rate means it compresses and extends easily, ensuring that forces like pump vibrations or thermal expansion are absorbed by the bellows itself, not transmitted down the line.

Absorbing Vibration and Shock

This easy compressibility makes PTFE bellows excellent dampers. They effectively absorb the constant, low-level vibrations from motors and pumps.

They also cushion the system against sudden shocks, such as water hammer, preventing that energy from reaching sensitive instruments or brittle pipe connections.

Protecting Fragile Components

This is one of the most critical applications. Systems often need to connect robust steel piping to delicate components made of glass, graphite, or certain ceramics.

A PTFE bellows acts as a flexible joint, preventing the stress of pipe misalignment, vibration, or expansion from shattering the fragile equipment.

How This Translates to Real-World Applications

The theoretical benefit of a low spring rate becomes a powerful problem-solver in complex industrial, laboratory, and manufacturing environments.

Handling Misalignment and Thermal Expansion

Pipes and equipment are rarely perfectly aligned. Furthermore, they expand and contract as process temperatures change.

A low-spring-rate bellows easily accommodates this constant movement, preventing the buildup of dangerous stress on nozzles, flanges, and supports.

Isolating Sensitive Instruments

Precision measurement instruments can be thrown off by even minor vibrations.

Placing a PTFE bellows between a pump and a sensor suite effectively isolates the instruments, ensuring their readings remain accurate and reliable.

Understanding the Full Picture: Complementary Properties

While the low spring rate is key for mechanical protection, it works in concert with other inherent properties of PTFE to create a uniquely effective solution. Understanding these factors is crucial for proper material selection.

The Role of Flex Life and Durability

A bellows is designed to move constantly. PTFE's extremely low coefficient of friction—its "slipperiness"—allows it to withstand millions of compression cycles without wear or fatigue.

This exceptional flex life reduces the risk of leaks and minimizes maintenance, directly impacting system safety and long-term operational cost.

The Importance of Chemical Inertness

Bellows are often used to convey highly corrosive or ultrapure substances. PTFE is virtually inert to almost all industrial chemicals.

This ensures the bellows will not be degraded by the material it is carrying, which is a critical safety factor when dealing with hazardous chemicals.

The Benefit of Non-Stick Surfaces

PTFE has a low surface energy, giving it its famous non-stick quality.

In sanitary or high-purity applications (like food, pharma, or semiconductors), this prevents material from sticking to the bellows walls, reducing the risk of contamination and blockages.

Making the Right Choice for Your System

Selecting a bellows requires matching the material's properties to your primary objective.

- If your primary focus is protecting fragile equipment (e.g., glass reactors, graphite heat exchangers): The low spring rate is the single most critical factor, as it directly prevents stress transfer.

- If your primary focus is vibration isolation for sensitive instruments: A low spring rate is essential for damping mechanical noise from pumps, motors, or other machinery.

- If your primary focus is handling aggressive chemicals or high-purity media: PTFE's chemical inertness and non-stick surface are paramount, with its low spring rate providing the necessary mechanical flexibility.

Ultimately, the low spring rate transforms a PTFE bellows from a simple connector into a critical component for system protection, stability, and longevity.

Summary Table:

| Benefit of Low Spring Rate | Key Outcome |

|---|---|

| Minimizes Force Transmission | Absorbs pump vibrations and thermal expansion, preventing stress transfer. |

| Absorbs Vibration & Shock | Dampens constant machinery vibrations and cushions against sudden shocks like water hammer. |

| Protects Fragile Components | Prevents stress from shattering delicate glass, graphite, or ceramic equipment connections. |

| Accommodates Misalignment | Compensates for imperfect pipe alignment and thermal movement without building stress. |

Protect your critical systems with precision-engineered PTFE bellows from KINTEK.

Our PTFE components, including custom bellows, are designed to solve your toughest challenges in semiconductor, medical, laboratory, and industrial applications. We combine the superior mechanical isolation of PTFE with our expertise in custom fabrication—from prototypes to high-volume orders—to ensure your sensitive equipment operates reliably and your processes remain uncontaminated.

Contact KINTEK today to discuss how our PTFE solutions can enhance the safety, efficiency, and longevity of your system.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

People Also Ask

- What challenges arise when machining PTFE (Teflon)? Overcome Softness, Heat, and Instability

- What industrial benefits do PTFE-machined parts offer? Achieve Peak Performance in Demanding Applications

- What are the unique properties of PTFE? The 3 Pillars Driving Demand for High-Performance Parts

- What chemical processing applications involve PTFE-machined parts? Essential Components for Corrosive & High-Purity Systems

- What fabrication services are available for PTFE? Shearing, Stamping, Laser Cutting, Molding & Machining