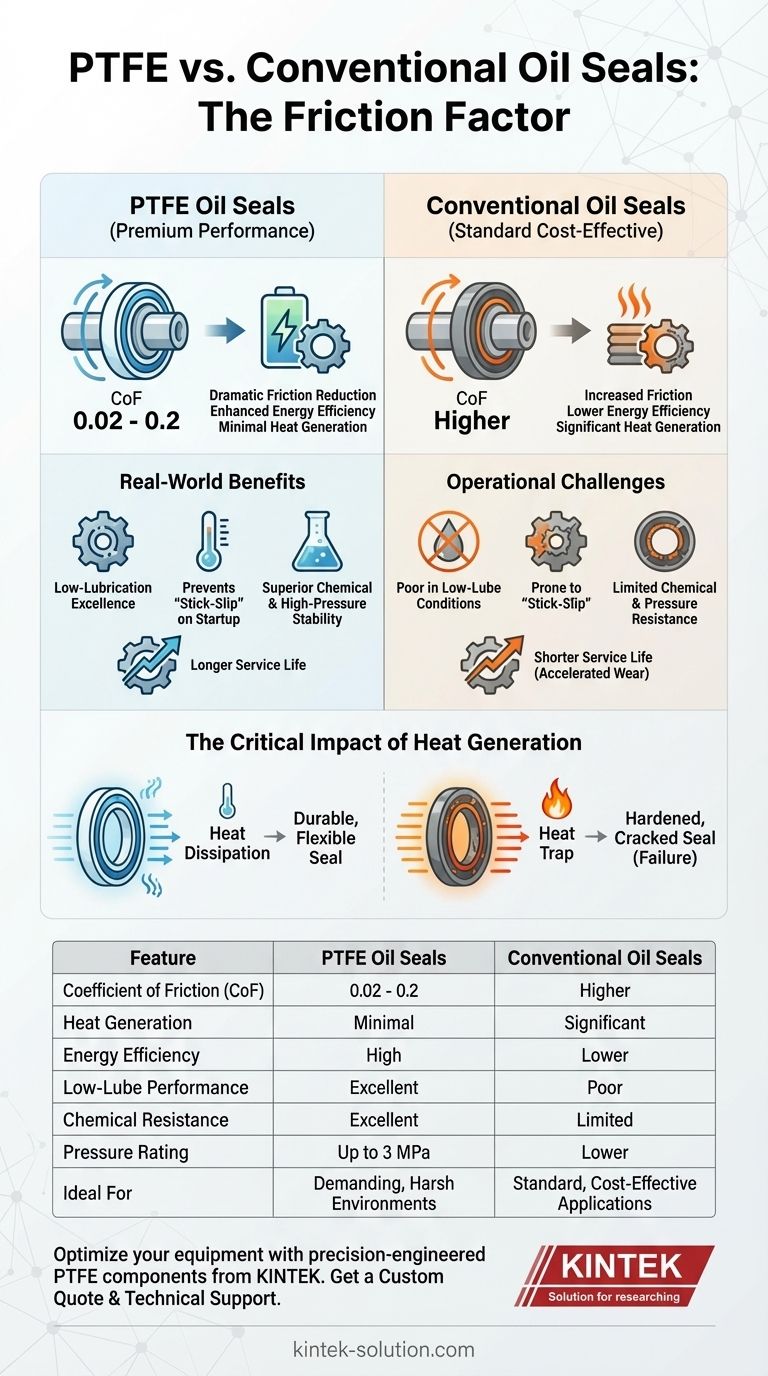

In a direct comparison, PTFE oil seals exhibit dramatically lower friction than conventional rubber oil seals. With a coefficient of friction around 0.02, PTFE seals significantly reduce energy loss and heat generation. This contrasts sharply with conventional seals, whose higher friction can lead to performance degradation and accelerated wear, especially under demanding conditions.

The essential difference is not just the friction value itself, but its operational consequence. PTFE's ultra-low friction translates directly into higher equipment efficiency and a longer service life in harsh environments, while conventional seals remain a reliable, cost-effective choice for standard-duty applications.

The Source of the Frictional Difference

The performance gap between PTFE and conventional seals begins at the molecular level. The material properties inherent to each type dictate how they behave under the stress of a rotating shaft.

The Ultra-Low Friction of PTFE

Polytetrafluoroethylene (PTFE) is one of the lowest-friction solid materials known in engineering. Its coefficient of friction typically ranges from 0.02 to 0.2, depending on the specific formulation and surface conditions.

This inherent slipperiness means less energy is required to turn the shaft, directly improving the mechanical efficiency of the equipment.

The Higher Friction of Conventional Seals

Conventional seals, typically made from nitrile or other elastomers, have a naturally higher coefficient of friction. While effective, they generate more resistance against the shaft.

This increased resistance is a direct source of energy loss and, more critically, heat.

The Critical Impact of Heat Generation

The primary drawback of higher friction is heat generation. This heat becomes trapped at the sealing lip, accelerating the aging process of the rubber material.

Over time, this can cause the seal to harden, crack, and ultimately fail, leading to leaks. PTFE's low friction minimizes this destructive heat cycle.

How Low Friction Impacts Real-World Performance

The theoretical advantage of low friction has several practical benefits that solve common engineering challenges, particularly in high-performance or sensitive equipment.

Enhancing Energy Efficiency

Reduced friction directly correlates to lower energy consumption. For continuously operating machinery, this reduction in parasitic drag can lead to noticeable savings in operating costs over the equipment's lifespan.

Excelling in Low-Lubrication Scenarios

PTFE's anti-friction properties make it exceptionally well-suited for applications with no oil or low-oil conditions. It can maintain its integrity and sealing function where a conventional seal would quickly overheat and fail.

Preventing "Stick-Slip" on Startup

A key advantage of PTFE is its ability to maintain low friction even after a prolonged shutdown. It resists the "stick-slip" phenomenon, where a seal initially sticks to the shaft on restart, causing a jump in required torque and potential seal damage.

Understanding the Trade-offs

While PTFE offers superior friction performance, the choice of a seal is never based on a single metric. A holistic view is necessary for a sound technical decision.

Performance vs. Cost

The primary advantage of conventional oil seals is their cost-effectiveness. For many common, well-lubricated applications without extreme temperatures or pressures, a standard rubber seal provides reliable performance at a much lower price point.

PTFE seals are a premium component, and their cost is justified in applications where their unique properties are required to ensure reliability and long service life.

Beyond Friction: Broader Material Advantages

The decision to use PTFE often involves its other superior characteristics. PTFE offers excellent chemical stability, resisting erosion from acids, bases, and solvents that would degrade a conventional seal.

Furthermore, PTFE seals can typically withstand significantly higher pressures (up to 3 MPa) than their conventional counterparts, making them essential for high-pressure hydraulic and pneumatic systems.

Making the Right Choice for Your Application

Selecting the correct seal requires matching the material's capabilities to the operational demands of the equipment.

- If your primary focus is maximizing efficiency and reliability in demanding conditions: The low friction, wear resistance, and superior durability of PTFE seals are the definitive choice.

- If your primary focus is cost-effectiveness for standard, well-lubricated machinery: Conventional rubber seals provide proven, reliable performance for a vast range of general applications.

- If your application involves harsh chemicals, high pressure, or temperature extremes: The robust material properties of PTFE, including its low friction, make it the necessary solution for operational safety and longevity.

Ultimately, understanding the profound link between friction, heat, and service life empowers you to select a seal that optimizes both equipment performance and long-term reliability.

Summary Table:

| Feature | PTFE Oil Seals | Conventional Oil Seals |

|---|---|---|

| Coefficient of Friction | 0.02 - 0.2 | Higher |

| Heat Generation | Minimal | Significant |

| Energy Efficiency | High | Lower |

| Performance in Low-Lube | Excellent | Poor |

| Chemical Resistance | Excellent | Limited |

| Pressure Rating | Up to 3 MPa | Lower |

| Ideal For | Demanding, harsh environments | Standard, cost-effective applications |

Optimize your equipment's performance and reliability with precision-engineered PTFE components from KINTEK.

Our advanced PTFE seals, liners, and labware are designed to deliver superior low-friction performance, exceptional chemical resistance, and long-lasting durability in the most demanding environments—from semiconductor and medical equipment to industrial and laboratory settings.

We specialize in custom fabrication, guiding your project from initial prototypes to high-volume production with meticulous attention to detail.

Contact us today to discuss how our PTFE solutions can solve your specific sealing challenges and enhance your operational efficiency.

Get a Custom Quote & Technical Support

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

People Also Ask

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications