At its core, the flexible lip design in a Teflon rotary shaft seal enhances performance by allowing it to maintain continuous, dynamic contact with the shaft. This adaptability ensures a consistent, tight seal that prevents fluid or gas leakage, even when faced with the mechanical imperfections and operational stresses inherent in rotating equipment.

The true value of a flexible Teflon seal isn't just its ability to block leaks, but its capacity to compensate for real-world operational challenges like shaft misalignment and runout, transforming a potential point of failure into a source of robust reliability.

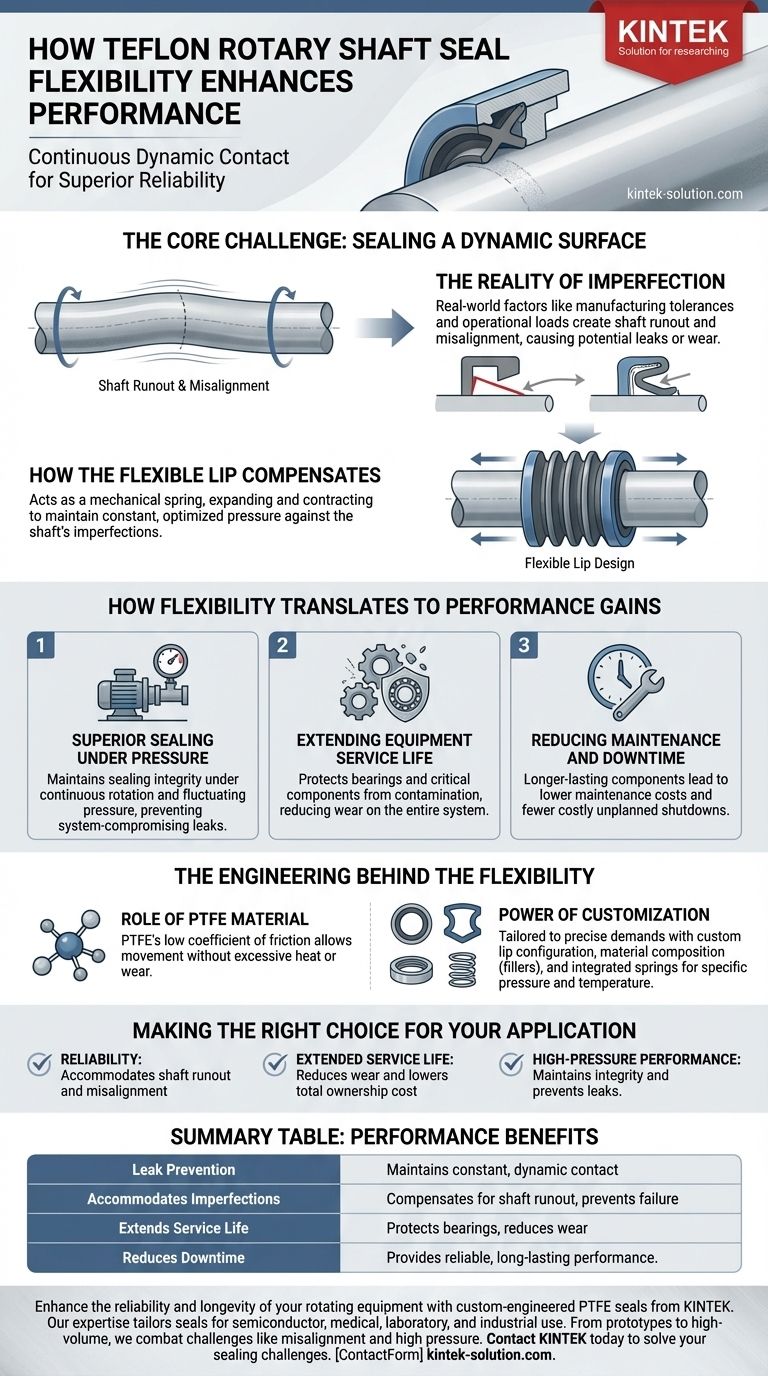

The Core Challenge: Sealing a Dynamic Surface

The Reality of Imperfection

In an ideal world, a rotating shaft would spin perfectly on its axis without any deviation. In reality, factors like manufacturing tolerances, wear, and operational loads create shaft runout (a wobble or eccentric rotation) and misalignment.

A rigid seal cannot compensate for this movement. It would either lose contact with the shaft, causing a leak, or create excessive friction and wear, leading to premature failure of both the seal and the equipment.

How the Flexible Lip Compensates

The flexible lip design, often described as a bellow, acts as a mechanical spring. It is engineered to move with the shaft's imperfections.

This design allows the seal to instantly expand or contract in response to any variation between the seal and the shaft surface. This ensures the sealing edge maintains constant, optimized pressure against the shaft at all times.

How Flexibility Translates to Performance Gains

Superior Sealing Under Pressure

In applications like pumps and compressors, the seal must perform under continuous rotation and fluctuating pressure.

The flexible lip maintains its integrity, ensuring a strong sealing force is always present. This prevents leakage that would otherwise compromise system efficiency and safety.

Extending Equipment Service Life

By preventing leaks, the flexible lip design protects bearings and other critical components from contamination by process fluids or external debris.

This superior protection reduces wear and tear on the entire system, significantly extending the service life of the equipment and the seal itself.

Reducing Maintenance and Downtime

Longer-lasting components and more reliable performance directly translate into lower maintenance costs.

Because these seals are less likely to fail unexpectedly, they reduce costly unplanned downtime, leading to more efficient and predictable operations.

The Engineering Behind the Flexibility

The Role of PTFE Material

The flexibility of the design works in concert with the unique properties of PTFE (Teflon). Its extremely low coefficient of friction means the lip can move and adapt without generating excessive heat or wear.

This combination of a smart mechanical design and an advanced material is what delivers the high performance.

The Power of Customization

This flexibility is not a one-size-fits-all feature. Manufacturers can tailor the seal to precise operational demands.

Key variables like lip configuration, material composition (using fillers for strength), and the integration of springs can be customized to meet specific requirements for pressure, temperature, and chemical exposure.

Making the Right Choice for Your Application

Choosing the right seal is about matching its design benefits to your primary operational goal.

- If your primary focus is reliability in imperfect conditions: The flexible lip's ability to accommodate shaft runout and misalignment is its most critical feature.

- If your primary focus is extending service life: The consistent, low-friction seal reduces wear on components, directly contributing to a lower total cost of ownership.

- If your primary focus is high-pressure performance: The design ensures the seal maintains its integrity and prevents leaks even under significant, continuous pressure.

Ultimately, investing in a seal with a properly engineered flexible lip design significantly improves the durability and efficiency of your rotating equipment.

Summary Table:

| Performance Benefit | How the Flexible Lip Design Achieves It |

|---|---|

| Leak Prevention | Maintains constant, dynamic contact with the shaft, even under pressure. |

| Accommodates Imperfections | Compensates for shaft runout and misalignment, preventing failure. |

| Extends Service Life | Protects bearings from contamination and reduces system wear. |

| Reduces Downtime | Provides reliable, long-lasting performance for predictable operations. |

Enhance the reliability and longevity of your rotating equipment with custom-engineered PTFE seals from KINTEK.

Our expertise in precision manufacturing allows us to tailor the flexibility, material composition, and lip configuration of our Teflon rotary shaft seals to your exact application demands—whether for semiconductor, medical, laboratory, or industrial use. From prototypes to high-volume orders, we deliver seals that combat real-world challenges like shaft misalignment and high pressure, directly reducing your maintenance costs and unplanned downtime.

Contact KINTEK today to discuss your specific requirements and discover how our custom PTFE components can solve your sealing challenges.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Rods for Advanced Industrial Applications

People Also Ask

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments