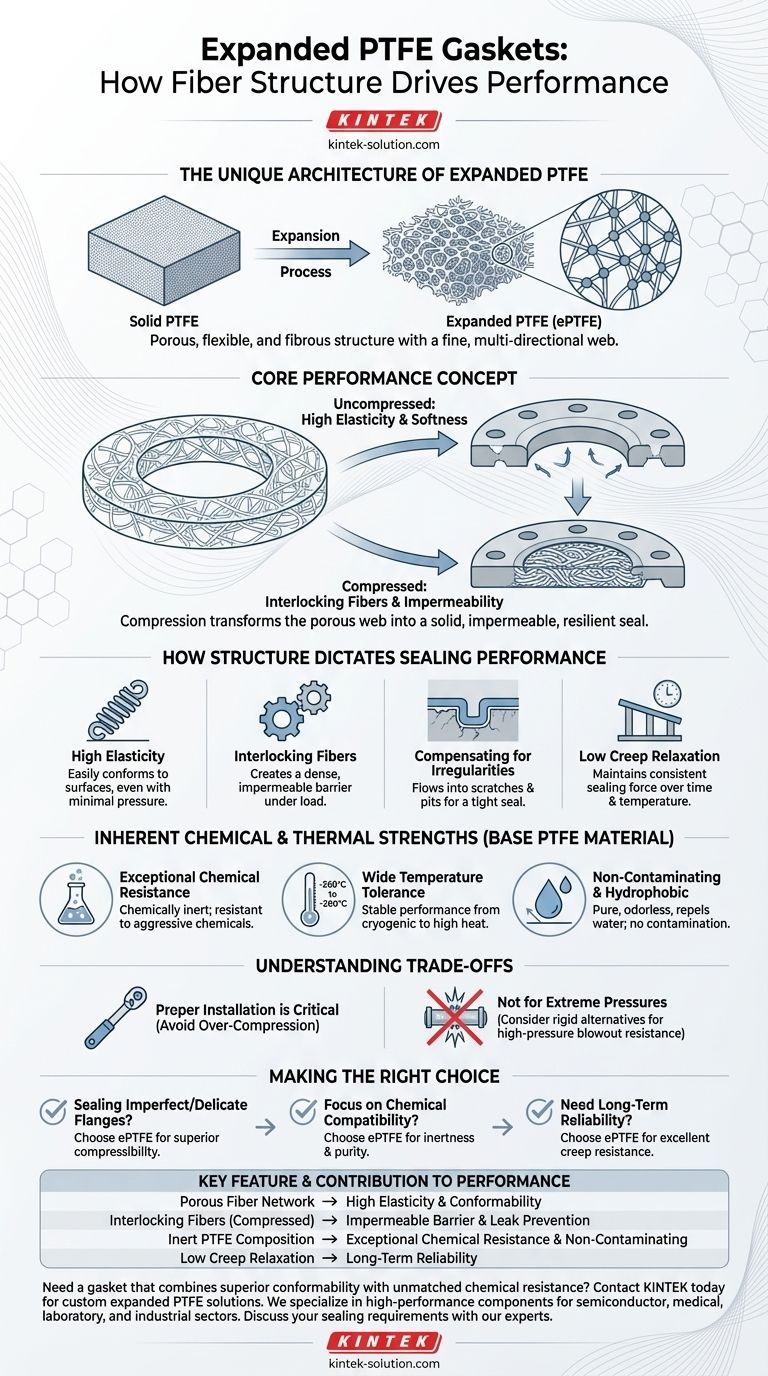

At its core, the performance of an expanded PTFE (ePTFE) gasket is dictated by its unique, porous fiber structure. This bi-directional network of fibers is highly elastic when uncompressed, allowing it to conform easily to surfaces. When compressed, these fibers interlock to create a solid, impermeable, and incredibly resilient seal that can compensate for flange imperfections.

The essential takeaway is that the expansion process transforms solid PTFE into a microscopic web. This structure combines the softness and conformability of a foam-like material with the strength and impermeability of a solid gasket once it is put under load.

The Unique Architecture of Expanded PTFE

To understand its performance, you must first understand its physical form. Unlike standard PTFE, which is a solid material, expanded PTFE has a fundamentally different architecture created through a specialized manufacturing process.

From Solid to Porous

Expanded PTFE begins as a standard PTFE polymer but is processed to create a porous, flexible, and fibrous structure. This transformation is what separates it from its solid, less-conformable pure PTFE counterparts.

A Bi-Directional Fiber Network

The result of this process is a fine, multi-directional web of fibers. This internal network is the source of the material's unique combination of softness and strength.

How Structure Dictates Sealing Performance

The physical structure of ePTFE directly translates to its superior sealing capabilities, especially in demanding or imperfect conditions. It behaves differently in its uncompressed and compressed states.

High Elasticity (Uncompressed State)

The porous, fibrous network makes the gasket exceptionally soft and elastic before installation. This allows it to be fitted easily without damage and to begin conforming to a flange surface with minimal pressure.

Interlocking Fibers (Compressed State)

When bolt load is applied, the magic happens. The space within the porous structure collapses, and the individual fibers interlock tightly. This creates a solid, dense, and impermeable barrier that prevents leaks.

Compensating for Irregularities

This high compressibility is a critical advantage. The gasket flows into minor scratches, pits, and waviness on flange faces, creating a tight seal where more rigid materials would fail.

Low Creep Relaxation

Once compressed, the interlocked fiber structure is incredibly stable. It resists the tendency to "creep" or flow out of the flange over time and under temperature changes, maintaining a consistent and reliable seal throughout its service life.

Inherent Chemical and Thermal Strengths

While the fiber structure dictates its mechanical performance, the base material—PTFE—provides its formidable environmental resistance.

Exceptional Chemical Resistance

Expanded PTFE is made of a fluoropolymer consisting only of carbon and fluorine. This makes it chemically inert and resistant to nearly all aggressive industrial chemicals, ensuring it will not corrode or degrade.

Wide Temperature Tolerance

The material is stable and performs reliably across an extremely wide temperature range, from cryogenic conditions up to +260°C (+500°F).

Non-Contaminating and Hydrophobic

Because it is pure and chemically inert, it is non-wetting, non-contaminating, and odorless. Its composition also makes it innately hydrophobic, meaning it repels water and water-based substances.

Understanding the Trade-offs

While ePTFE is highly versatile, no material is perfect for every scenario. Understanding its limitations is key to using it correctly.

Proper Installation is Critical

The softness that makes ePTFE so conformable also means it can be damaged by excessive compression. Following correct torque specifications is crucial to avoid crushing the fiber structure and compromising the seal.

Not for Extreme Pressures

While excellent for a vast range of applications, its softness makes it less suitable for extremely high-pressure systems where a rigid metallic or semi-metallic gasket might be required to resist blowout.

Making the Right Choice for Your Application

Selecting the correct gasket requires matching the material's strengths to your primary operational goal.

- If your primary focus is sealing imperfect or delicate flanges: The superior compressibility of ePTFE allows it to create a tight seal on irregular surfaces with minimal bolt load.

- If your primary focus is chemical compatibility and purity: The 100% pure, inert PTFE composition makes it a premier choice for aggressive media or systems where contamination is unacceptable.

- If your primary focus is long-term reliability: The excellent creep resistance ensures the gasket maintains its sealing force over extended periods and through thermal cycles.

Ultimately, the engineered fiber structure of expanded PTFE delivers a unique combination of forgiveness and durability, solving sealing challenges that other materials cannot.

Summary Table:

| Key Feature | Contribution to Performance |

|---|---|

| Porous Fiber Network | Provides high elasticity for easy installation and excellent conformability to imperfect surfaces. |

| Interlocking Fibers (Compressed) | Creates a solid, impermeable barrier under load, preventing leaks. |

| Inert PTFE Composition | Delivers exceptional chemical resistance and is non-contaminating. |

| Low Creep Relaxation | Maintains sealing force over time and through thermal cycles for long-term reliability. |

Need a gasket that combines superior conformability with unmatched chemical resistance?

At KINTEK, we specialize in manufacturing high-performance PTFE components, including custom expanded PTFE gaskets. Our expertise in precision fabrication ensures you get a reliable seal that compensates for flange imperfections and withstands aggressive media.

Whether you're in the semiconductor, medical, laboratory, or industrial sector, we can provide solutions from prototypes to high-volume orders.

Contact KINTEK today to discuss your specific sealing requirements and let our experts help you achieve a leak-free operation.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are the unique properties of PTFE? The 3 Pillars Driving Demand for High-Performance Parts

- What finishing techniques are effective for machined Teflon parts? Achieve Functional Performance and Dimensional Stability

- What chemical processing applications involve PTFE-machined parts? Essential Components for Corrosive & High-Purity Systems

- What fabrication services are available for PTFE? Shearing, Stamping, Laser Cutting, Molding & Machining

- What industrial benefits do PTFE-machined parts offer? Achieve Peak Performance in Demanding Applications