The durability of PTFE vials directly contributes to significant cost savings by dramatically reducing their replacement frequency. Because PTFE (Polytetrafluoroethylene) is an exceptionally robust material resistant to chemical attack, extreme temperatures, and physical degradation, a single vial can be used for years, minimizing the recurring expense of purchasing new labware.

While the initial investment in PTFE vials may be higher than for other materials, their exceptional durability provides a lower total cost of ownership by virtually eliminating replacement costs, preventing expensive sample loss, and ensuring the integrity of your experiments.

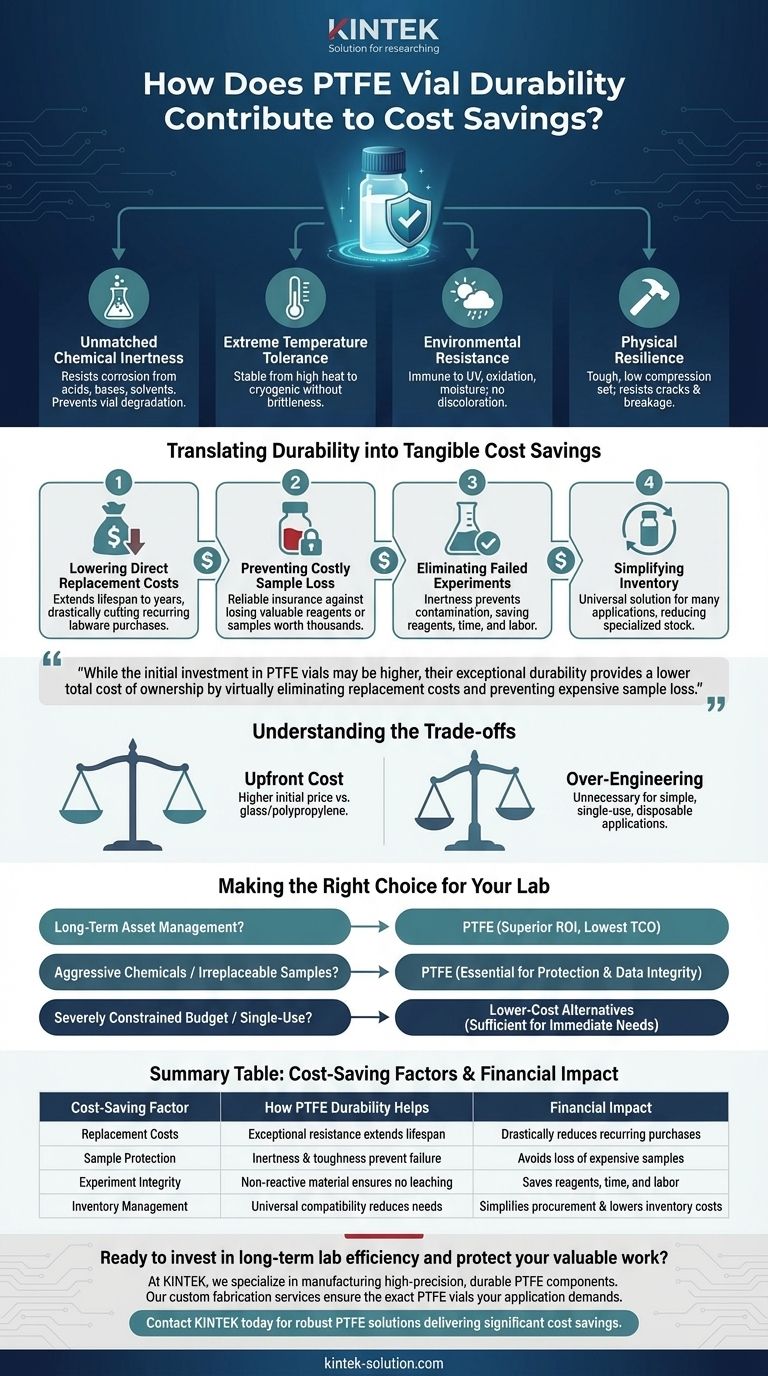

Deconstructing "Durability": What Makes PTFE Vials Robust?

To understand the cost benefits, we must first define what "durability" means in a demanding laboratory environment. It is not a single feature but a combination of powerful material properties.

Unmatched Chemical Inertness

PTFE is famously non-reactive and resists corrosion from nearly all acids, bases, and organic solvents. This prevents the vial itself from degrading, which is a common failure point for less robust materials when exposed to aggressive reagents.

Extreme Temperature Tolerance

With a very high melting point and stability across a vast temperature range, PTFE vials can be used for high-temperature reactions or cryogenic storage without becoming brittle or losing their structural integrity.

Resistance to Environmental Factors

PTFE is immune to damage from UV light, oxidation, and moisture. Unlike many plastics, it will not discolor, weaken, or become brittle over time, even with prolonged exposure to harsh environmental conditions.

Physical Resilience

The material has a low compression set and inherent toughness, meaning it resists physical damage from handling. This resilience prevents cracks and breakage that would render other vials unusable.

Translating Durability into Tangible Cost Savings

Each aspect of PTFE's durability translates directly into measurable financial benefits that go far beyond simple replacement costs.

Lowering Direct Replacement Costs

This is the most obvious benefit. A lab that replaces glass or standard plastic vials quarterly or annually might use the same set of PTFE vials for several years. This dramatically cuts down the line item for consumable labware in any budget.

Preventing Costly Sample Loss

A failed vial means a lost sample. The cost of a rare reagent, a patient sample, or a synthesized compound that took weeks to create can easily run into thousands of dollars. The reliability of a PTFE vial acts as an insurance policy against this catastrophic—and expensive—type of failure.

Eliminating Failed Experiments from Contamination

When a less-durable vial degrades, it can leach impurities into the sample, contaminating it and invalidating experimental results. This wastes not only the sample but also valuable reagents, instrument time, and researcher labor. PTFE's inertness ensures purity and prevents these costly setbacks.

Simplifying Inventory and Procurement

Because PTFE vials are suitable for such a wide range of chemicals and temperatures, they can serve as a universal solution for many lab applications. This simplifies inventory management and procurement, reducing the need to stock multiple types of specialized vials.

Understanding the Trade-offs

While highly beneficial, PTFE is not the default choice for every situation. Acknowledging its limitations is key to making an informed decision.

The Upfront Cost Consideration

The primary drawback of PTFE is its higher initial purchase price compared to materials like polypropylene or glass. The cost-benefit analysis hinges on long-term use and the value of the samples being stored.

When Over-Engineering Isn't Necessary

For simple, aqueous solutions in a single-use or disposable application, the extreme durability of PTFE is unnecessary. In these cases, a less expensive, disposable vial is the more economical choice. The true value of PTFE is realized in applications that are long-term, repetitive, or chemically aggressive.

Making the Right Choice for Your Lab

Your decision should be guided by your lab's specific operational and budgetary goals.

- If your primary focus is long-term asset management: PTFE's longevity offers a superior return on investment and the lowest total cost of ownership.

- If you work with aggressive chemicals or irreplaceable samples: PTFE's chemical inertness and physical resilience are essential for protecting your work and ensuring data integrity.

- If your budget is severely constrained for non-critical, single-use applications: Lower-cost alternatives may be sufficient for your immediate needs.

Ultimately, choosing a PTFE vial is an investment in the long-term efficiency, reliability, and financial stability of your laboratory operations.

Summary Table:

| Cost-Saving Factor | How PTFE Durability Helps | Financial Impact |

|---|---|---|

| Replacement Costs | Exceptional chemical & temperature resistance extends lifespan to years. | Drastically reduces recurring labware purchases. |

| Sample Protection | Inertness and physical toughness prevent vial failure and contamination. | Avoids loss of expensive, irreplaceable samples. |

| Experiment Integrity | Non-reactive material ensures no leaching, preventing invalid results. | Saves on wasted reagents, instrument time, and labor. |

| Inventory Management | Universal chemical compatibility reduces need for specialized vials. | Simplifies procurement and lowers inventory costs. |

Ready to invest in long-term lab efficiency and protect your valuable work?

At KINTEK, we specialize in manufacturing high-precision, durable PTFE components—including seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors. Our custom fabrication services, from prototypes to high-volume orders, ensure you get the exact PTFE vials your application demands.

Contact KINTEK today to discuss how our robust PTFE solutions can deliver significant cost savings and unparalleled reliability for your specific needs.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- PTFE Chemical Solvent Sampling Spoon

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Bottles for Diverse Industrial Applications

People Also Ask

- How does PTFE compare to other low-friction plastics like UHMW-PE and Nylon? A Guide to Material Selection

- How is PTFE used in industrial processes? Maximize Safety and Efficiency

- Why is dimensional stability a concern when machining PTFE? Ensure Accurate, Stable PTFE Components

- What are some applications of CNC machined PTFE parts? Critical Components for Medical, Electrical & Food Industries

- What is the hardness range of PTFE on the Shore D scale? Leveraging Its Softness for Superior Performance