The primary benefit of Teflon's chemical resistance is its ability to create a near-impermeable barrier in highly corrosive industrial environments. Made from PTFE (polytetrafluoroethylene), these plastic sheets do not degrade when exposed to aggressive acids, bases, and solvents. This unique property protects critical equipment, extends its operational lifespan, and drastically reduces costly downtime and maintenance.

The core value of Teflon in industry is not merely its ability to survive harsh chemicals, but its capacity to provide unwavering operational reliability. Its chemical inertness ensures that processes can run continuously without the risk of material failure or product contamination.

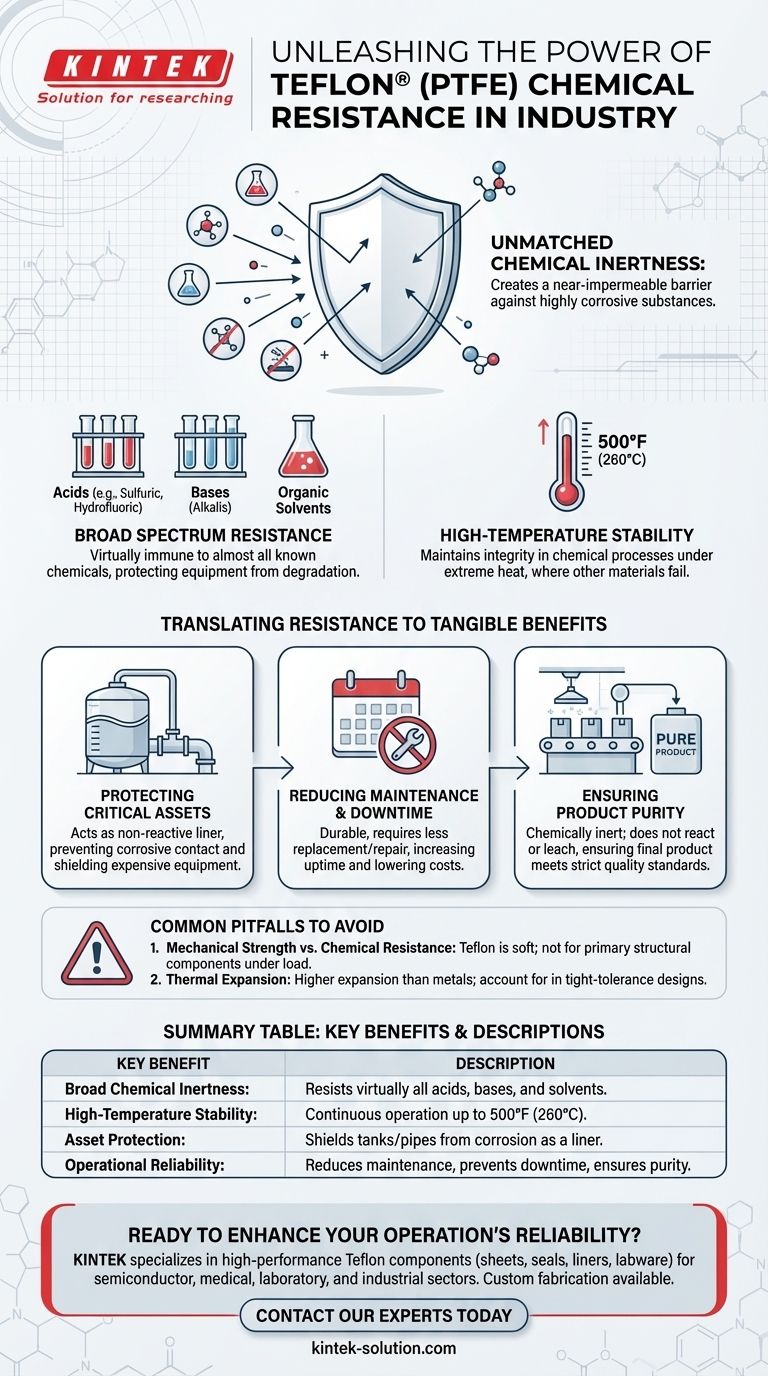

The Foundation: Unmatched Chemical Inertness

Teflon's effectiveness stems from its unique molecular structure, which renders it almost universally inert. This makes it a foundational material for any industry handling aggressive substances.

Resistance to a Broad Spectrum of Chemicals

PTFE is virtually immune to almost all known chemicals. This includes highly corrosive substances that would quickly degrade metals, alloys, and other plastics.

It reliably withstands constant exposure to strong acids (like sulfuric and hydrofluoric acid), aggressive bases (alkalis), and a wide array of organic solvents.

Stability at High Temperatures

This chemical resistance is not compromised by heat. Teflon sheets maintain their integrity and protective properties at continuous service temperatures up to 500°F (260°C).

This makes it exceptionally valuable for chemical processes that occur under high-temperature conditions where other materials would fail.

How Resistance Translates to Tangible Benefits

The theoretical property of chemical resistance delivers concrete, measurable advantages in demanding industrial settings, from chemical processing plants to semiconductor fabrication facilities.

Protecting Critical Assets

Teflon sheets are frequently used as liners for tanks, vessels, and pipelines. By preventing corrosive chemicals from making contact with the underlying structure, they protect expensive capital equipment from degradation.

This application is critical in systems handling substances like sulfuric acid or hydrofluoric acid, where a material breach would be catastrophic.

Reducing Maintenance and Downtime

Equipment lined or sealed with PTFE requires far less frequent replacement and repair. Its durability translates directly to increased uptime and lower maintenance budgets.

Because it does not degrade, it prevents leaks and failures that would otherwise shut down an entire production line.

Ensuring Product Purity

In industries like pharmaceuticals, food processing, and semiconductors, even microscopic contamination can ruin a batch. Since Teflon is chemically inert, it does not react with or leach into the substances it contacts.

This ensures that the final product remains pure and meets strict quality standards.

Common Pitfalls to Avoid

While its chemical properties are exceptional, understanding its limitations is key to successful application. Misusing Teflon can lead to premature failure in applications where it is not the right fit.

Confusing Chemical Resistance with Mechanical Strength

Teflon is a relatively soft material. Its incredible chemical stability does not mean it has high tensile or compressive strength compared to metals or engineering plastics.

It can be prone to deformation ("creep") under sustained load and is not suitable for use as a primary structural component.

Overlooking Thermal Expansion

While PTFE has a low thermal expansion coefficient for a polymer, it is still higher than that of most metals. In applications with tight tolerances that undergo significant temperature swings, this expansion must be accounted for in the design.

Ignoring this can lead to stress and failure in precision assemblies.

Making the Right Choice for Your Application

To leverage Teflon's properties effectively, align its strengths with your primary operational goal.

- If your primary focus is asset protection in corrosive environments: Teflon sheets are an unparalleled choice for liners in tanks and pipelines that handle aggressive chemicals.

- If your primary focus is reliability in chemical sealing: PTFE's inertness and temperature stability make it a top-tier material for gaskets, seals, and gland fillers.

- If your primary focus is preventing product contamination: The non-reactive nature of Teflon is essential for wetted parts in pharmaceutical, food, and semiconductor manufacturing equipment.

By understanding its profound chemical inertness, you can engineer systems that are more resilient, reliable, and cost-effective.

Summary Table:

| Key Benefit | Description |

|---|---|

| Broad Chemical Inertness | Resists virtually all acids, bases, and solvents, including sulfuric and hydrofluoric acid. |

| High-Temperature Stability | Maintains integrity and protective properties at continuous temperatures up to 500°F (260°C). |

| Asset Protection | Acts as a non-reactive liner for tanks and pipes, shielding expensive equipment from corrosion. |

| Operational Reliability | Reduces maintenance, prevents costly downtime, and ensures product purity by eliminating contamination. |

Ready to enhance your operation's reliability with precision-engineered PTFE components?

KINTEK specializes in manufacturing high-performance Teflon plastic sheets, seals, liners, and custom labware. Our components are designed to provide unwavering chemical resistance, protecting your critical assets in the semiconductor, medical, laboratory, and industrial sectors. We offer custom fabrication from prototypes to high-volume orders, ensuring a perfect fit for your specific application.

Contact our experts today to discuss your requirements and discover how our PTFE solutions can safeguard your processes, reduce downtime, and ensure product purity.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability