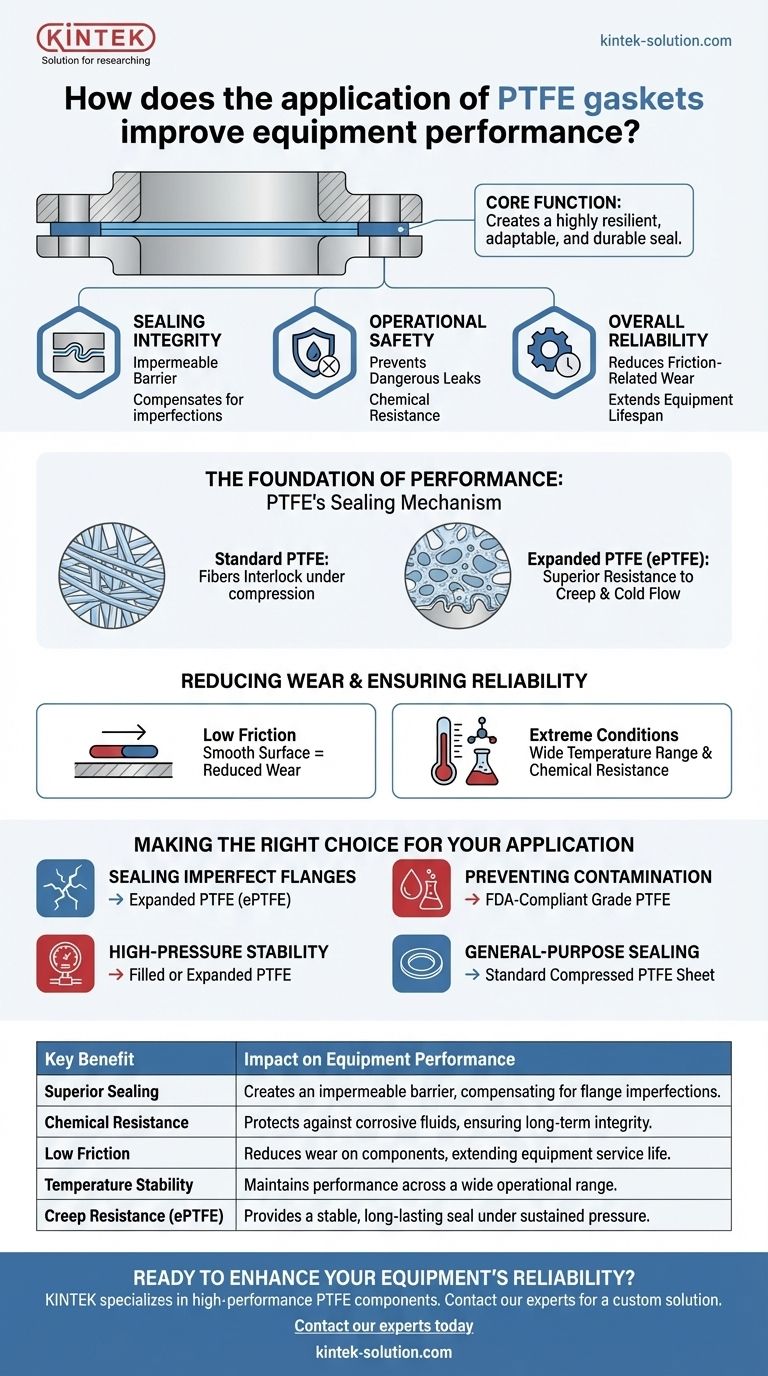

At its core, applying Polytetrafluoroethylene (PTFE) gaskets improves equipment performance by creating a highly resilient, adaptable, and durable seal. This directly enhances the sealing integrity, operational safety, and overall reliability of machinery by protecting it from leaks, chemical attack, and friction-related wear.

The true value of a PTFE gasket lies in its unique material properties. Its ability to conform to surface imperfections, resist extreme conditions, and reduce friction allows it to solve common points of failure where other sealing materials fall short.

The Foundation of Performance: Unpacking PTFE's Sealing Mechanism

To understand how PTFE improves equipment, we must first look at how it functions at the microscopic level. Its effectiveness is not accidental; it is a direct result of its unique physical structure.

How PTFE Creates an Impermeable Barrier

The material's fine, bi-directional fiber structure is highly elastic when uncompressed. Once placed under load, these fibers interlock tightly.

This creates a solid, balanced, and impermeable structure. Crucially, this allows the gasket to compensate for minor surface imperfections on flange faces, ensuring a complete seal where more rigid materials might fail.

The Advantage of Expanded PTFE (ePTFE)

Expanded PTFE (ePTFE) represents an evolution of this technology. It offers superior resistance to creep and cold flow—the tendency of a material to deform under sustained pressure.

ePTFE adapts even better to irregular flange surfaces and compensates for flange deformation during operation. This results in a more stable, long-lasting seal, especially in demanding applications.

Extending Equipment Lifespan and Safety

A better seal is only part of the equation. PTFE's other properties contribute directly to the longevity and safe operation of the equipment it's installed in.

Reducing Wear Through Low Friction

PTFE has an exceptionally low coefficient of friction. This creates a smooth surface that significantly reduces wear and tear on the sealing parts it contacts.

By minimizing this mechanical stress, the gasket not only lasts longer itself but also helps extend the service life of expensive equipment components like flange faces.

Ensuring Reliability Under Pressure

PTFE flange gaskets are engineered to maintain their structural integrity even under significant pressure variations.

This stability provides a reliable seal that prevents dangerous leaks of chemicals or high-pressure fluids, directly enhancing the safety of the industrial environment.

Withstanding Extreme Conditions

Beyond pressure, PTFE gaskets offer a wide operational temperature range and excellent chemical resistance. They also provide electrical insulation and have non-stick properties, preventing material buildup on the seal.

Understanding the Trade-offs and Variations

While highly effective, not all PTFE gaskets are the same. Understanding the differences is critical to selecting the right material for a specific application.

The Challenge of Creep and Cold Flow

Standard, unfilled PTFE can be susceptible to creep or cold flow, especially under high mechanical loads or elevated temperatures. This can cause the seal to loosen over time.

This is the primary trade-off of the base material and the reason that modified versions were developed.

The Role of Fillers and Expansion

To counteract creep, manufacturers produce filled PTFE (with materials like glass or carbon) or use expanded PTFE (ePTFE).

These variations enhance the gasket's mechanical strength, temperature resistance, and dimensional stability, making them suitable for more demanding service conditions.

Choosing the Right Form and Fit

PTFE is available in various forms, including compressed sheets and custom-fabricated gaskets tailored to specific pipe sizes and equipment.

This versatility allows you to select a material that precisely matches your operational needs, balancing performance requirements with cost considerations. It can be used effectively on everything from pipeline flanges and tanks to brittle materials like glass, porcelain, and graphite.

Making the Right Choice for Your Application

Selecting the correct PTFE gasket requires matching the material's properties to your primary operational goal.

- If your primary focus is sealing imperfect, damaged, or brittle flanges: Expanded PTFE (ePTFE) is the superior choice due to its exceptional conformability.

- If your primary focus is preventing product contamination in food or pharma: Ensure you select a non-toxic, FDA-compliant grade of PTFE.

- If your primary focus is stability in high-pressure or high-temperature systems: A filled or expanded PTFE gasket will provide the necessary resistance to creep and cold flow.

- If your primary focus is general-purpose sealing with moderate demands: A standard, compressed PTFE sheet gasket can provide a reliable and cost-effective solution.

By understanding its core properties and variations, you can leverage PTFE to achieve a new standard of operational reliability in your equipment.

Summary Table:

| Key Benefit | Impact on Equipment Performance |

|---|---|

| Superior Sealing | Creates an impermeable barrier, compensating for flange imperfections. |

| Chemical Resistance | Protects against corrosive fluids, ensuring long-term integrity. |

| Low Friction | Reduces wear on components, extending equipment service life. |

| Temperature Stability | Maintains performance across a wide operational range. |

| Creep Resistance (ePTFE) | Provides a stable, long-lasting seal under sustained pressure. |

Ready to enhance your equipment's reliability with precision PTFE gaskets?

At KINTEK, we specialize in manufacturing high-performance PTFE components, including seals, gaskets, and liners, for the semiconductor, medical, laboratory, and industrial sectors. Our expertise in custom fabrication—from prototypes to high-volume orders—ensures you get a sealing solution tailored to your specific operational demands, whether you need superior chemical resistance, temperature stability, or conformability for brittle flanges.

Contact our experts today to discuss your application and receive a custom solution that boosts your equipment's performance and longevity.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability