The primary benefit of PTFE's anti-adhesion is its ability to ensure both process purity and mechanical integrity. This well-known "non-stick" quality prevents impurities from clinging to the gasket surface, ensuring unobstructed flow. At the same time, its low-friction nature allows connected mechanical parts, like valves, to operate smoothly with significantly less wear and tear.

The true value of a PTFE gasket is not just one feature, but the combination of its non-stick surface, chemical inertness, and thermal stability. These properties work in concert to minimize maintenance, prevent leaks, and extend the operational life of your equipment.

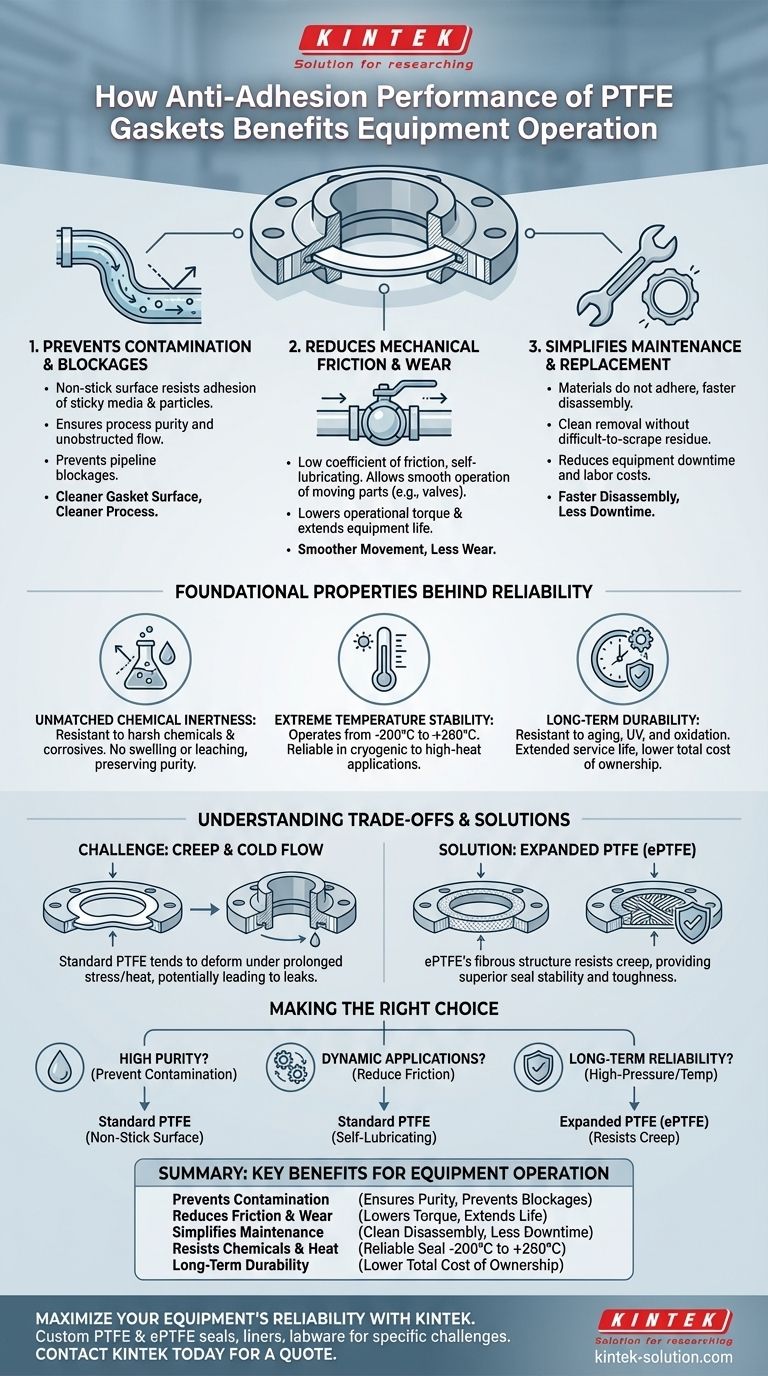

How Anti-Adhesion Directly Improves Operation

The non-stick characteristic of Polytetrafluoroethylene (PTFE) is more than a convenience; it is a core engineering advantage that directly translates to better equipment performance and reliability.

Preventing Contamination and Blockages

The surface of a PTFE gasket resists adhesion from nearly all substances, including sticky process media and solid particles.

This ensures that the gasket itself does not become a source of contamination. It also guarantees a smooth, unobstructed path for fluids, preventing potential blockages in pipelines.

Reducing Mechanical Friction and Wear

PTFE has an extremely low coefficient of friction, making it a self-lubricating material.

In dynamic applications, such as a ball valve, this property allows the components to move smoothly against the gasket. This reduces the torque needed for operation and dramatically minimizes wear over time, extending the life of the valve.

Simplifying Maintenance and Gasket Replacement

Because materials do not adhere to the gasket, the disassembly and cleaning process is significantly faster.

Old gaskets can be removed cleanly without leaving behind difficult-to-scrape residue. This reduces equipment downtime and labor costs during routine maintenance cycles.

The Foundational Properties Behind PTFE's Reliability

The anti-adhesion performance of PTFE is supported by a set of fundamental material properties that make it a uniquely reliable sealing solution in demanding industrial environments.

Unmatched Chemical Inertness

PTFE is virtually indestructible by most harsh chemicals, acids, and corrosive agents.

This means the gasket will not degrade, swell, or leach unwanted substances into the process media, ensuring a secure seal and preserving product purity.

Extreme Temperature Stability

PTFE gaskets maintain their integrity and sealing capability across an exceptionally wide temperature range, from -200°C to +260°C (-328°F to +500°F).

This allows them to perform reliably in applications involving cryogenic fluids or high-temperature processes without becoming brittle or soft.

Long-Term Durability

Unlike many other materials, PTFE is highly resistant to aging, UV radiation, and oxidation.

This inherent stability results in a very long service life, even under continuous use. For asset owners, this translates directly to lower maintenance frequency and a reduced total cost of ownership.

Understanding the Trade-offs and Solutions

No material is perfect for every application. To use PTFE effectively, it is critical to understand its primary limitation and the modern solutions developed to address it.

The Challenge of Creep and Cold Flow

The main drawback of standard PTFE is its tendency to "creep" or cold flow. This is a slow deformation of the material when subjected to prolonged compressive stress, especially at elevated temperatures.

Over time, this can reduce the sealing pressure on a flange, potentially leading to leaks.

The Solution: Expanded PTFE (ePTFE)

To solve this problem, manufacturers developed expanded PTFE (ePTFE). This material has a multi-directional fibrous structure.

This structure gives ePTFE exceptional toughness and fundamentally resists the creep and cold flow issues common in standard PTFE. It provides the chemical and thermal benefits of PTFE with vastly improved seal stability.

Making the Right Choice for Your Goal

Selecting the correct gasket material is essential for maximizing safety and operational efficiency. Your specific goal will determine the best choice.

- If your primary focus is preventing contamination in high-purity systems: The non-stick surface of standard PTFE is ideal for keeping process media clean.

- If your primary focus is reducing friction in dynamic applications (like valves): PTFE's self-lubricating nature is unmatched for minimizing wear and operational torque.

- If your primary focus is long-term, leak-free reliability in high-pressure or high-temperature static seals: Expanded PTFE (ePTFE) is the superior choice to mitigate the risk of creep.

By understanding these properties and trade-offs, you can confidently select the right gasket to enhance your equipment's safety, reliability, and efficiency.

Summary Table:

| Key Benefit | Impact on Equipment Operation |

|---|---|

| Prevents Contamination | Ensures process purity and prevents blockages in pipelines. |

| Reduces Friction & Wear | Lowers operational torque and extends the life of valves and moving parts. |

| Simplifies Maintenance | Allows for clean, fast disassembly, reducing downtime and labor costs. |

| Resists Chemicals & Heat | Maintains a reliable seal from -200°C to +260°C, even with harsh media. |

| Long-Term Durability | Provides a lower total cost of ownership through extended service life. |

Maximize your equipment's reliability and efficiency with precision PTFE components from KINTEK.

Whether your priority is absolute purity for semiconductor or medical processes, reduced wear for industrial valves, or long-term leak-free performance, we have the solution. Our expertise in custom fabricating standard and expanded PTFE (ePTFE) seals, liners, and labware ensures you get the perfect part for your specific challenge, from prototype to high-volume production.

Contact KINTEK today to discuss your application and request a quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications