At its core, Teflon's benefit as an electrical insulator is its ability to reliably prevent the flow of electricity where it isn't wanted. This property makes it indispensable for components like wiring, connectors, and insulating sleeves, ensuring both safety and signal integrity in critical electronic and electrical systems.

The true value of Teflon is not just its ability to insulate, but its unique capacity to maintain elite electrical performance under extreme conditions—high heat, corrosive chemicals, and physical stress—where lesser materials would quickly fail.

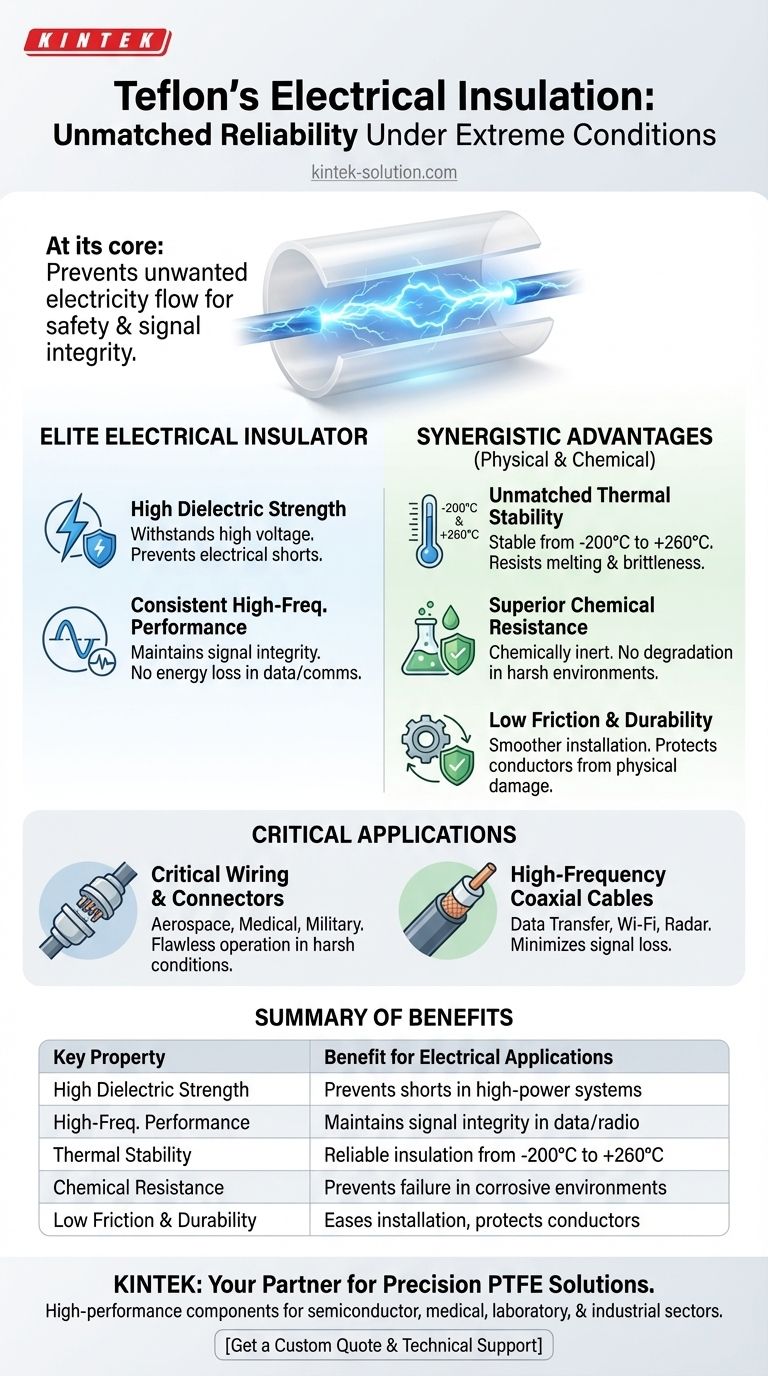

What Makes Teflon an Elite Electrical Insulator?

The term "insulator" is simple, but the qualities that make an insulator effective, especially in demanding applications, are more specific. Teflon (PTFE) excels due to a combination of inherent electrical and physical properties.

High Dielectric Strength

Dielectric strength is a measure of an insulating material's ability to withstand high voltage without breaking down and allowing current to pass through.

Teflon possesses a very high dielectric strength. This means it can be used to insulate high-voltage wiring without risk of an electrical short, making it essential for high-power applications.

Consistent Performance Across Frequencies

Many insulators lose their effectiveness as the frequency of the electrical signal increases.

Teflon maintains its excellent insulating properties even at very high frequencies, such as those used in radio and data communications. This ensures signal integrity and prevents energy loss in critical communication cables.

The Synergistic Advantage: Why Other Properties Matter

Teflon's electrical performance alone is impressive, but its dominance in certain fields comes from how this property is complemented by its other unique characteristics. An insulator is only as good as its ability to survive its operating environment.

Unmatched Thermal Stability

Most common insulators like rubber or PVC will melt, degrade, or become brittle at extreme temperatures.

Teflon remains a stable and effective insulator across an exceptionally wide temperature range, from -200°C to +260°C. This allows it to be used in aerospace, industrial manufacturing, and engine components where other materials would fail.

Superior Chemical Resistance

In industrial or medical settings, wiring and connectors are often exposed to oils, solvents, and corrosive chemicals.

Teflon is chemically inert to nearly all substances. This ensures the insulation will not dissolve or degrade, preventing dangerous electrical failures in chemically harsh environments.

Low Friction and Durability

The physical process of installing wires can cause damage from pulling them through tight conduits or around sharp corners.

Teflon's famously low friction and high wear resistance make installation smoother and protect the underlying conductor from physical damage, ensuring long-term reliability.

Understanding the Application Context

These combined properties make Teflon the material of choice when failure is not an option. Its benefits are most pronounced in applications that push the limits of performance.

Critical Wiring and Connectors

In applications like aerospace, medical devices, and military equipment, a single connection failure can have catastrophic consequences. Teflon provides the necessary reliability to ensure systems operate flawlessly under intense heat, vibration, and potential chemical exposure.

High-Frequency Coaxial Cables

For high-speed data transfer, Wi-Fi, and radar systems, preserving the purity of the signal is paramount. Teflon is used as the dielectric insulator inside these cables to minimize signal loss and ensure information is transmitted accurately.

Making the Right Choice for Your Application

Choosing an insulating material requires matching its properties to the demands of the environment.

- If your primary focus is reliability in extreme temperatures or chemical environments: Teflon's combined thermal and chemical stability makes it the definitive choice over standard plastics.

- If your primary focus is preserving signal integrity in high-frequency systems: Teflon's consistent dielectric properties ensure minimal signal loss for data, radio, and microwave applications.

- If your application involves complex installation or potential for physical abrasion: Teflon's low friction and durability protect the wiring and simplify the manufacturing process.

Ultimately, specifying Teflon is a decision to invest in unparalleled reliability where operational integrity is non-negotiable.

Summary Table:

| Key Property | Benefit for Electrical Applications |

|---|---|

| High Dielectric Strength | Withstands high voltage, preventing shorts in high-power systems. |

| Stable High-Frequency Performance | Maintains signal integrity in data, radio, and microwave communications. |

| Extreme Thermal Stability (-200°C to +260°C) | Provides reliable insulation where other materials would melt or degrade. |

| Superior Chemical Resistance | Prevents insulation failure in harsh, corrosive environments. |

| Low Friction & Durability | Eases installation and protects conductors from physical damage. |

Need High-Performance PTFE Components for Your Critical Applications?

When failure is not an option, you need a partner who understands the critical role of precision insulation. KINTEK specializes in manufacturing high-quality, custom PTFE components—including seals, liners, labware, and complex insulating parts—for the semiconductor, medical, laboratory, and industrial sectors.

We ensure your components deliver the unparalleled electrical performance and reliability your projects demand. From prototypes to high-volume production, our expertise in PTFE fabrication guarantees a perfect fit for your most challenging environments.

Contact us today to discuss your specific requirements and let our solutions power your success.

Get a Custom Quote & Technical Support

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications