At a molecular level, Teflon's primary differentiator is its unique fluorine-based chemistry. This structure of incredibly strong carbon-fluorine bonds grants it a combination of properties rarely found together in common plastics: extreme chemical inertness, high-temperature tolerance, and an incredibly low coefficient of friction. While most plastics excel in one or two areas, Teflon provides a unique trifecta of resilience for extreme environments.

The fundamental difference isn't that Teflon is simply "better," but that it occupies a specialized niche. Its fluorine-carbon bonds create an inert, non-stick, and heat-resistant material ideal for demanding applications where conventional plastics like polyethylene or PVC would quickly degrade and fail.

The Source of Teflon's Unique Properties

Teflon isn't just one material; it's a family of fluoropolymers, with PTFE (polytetrafluoroethylene) being the most well-known. Its distinct characteristics all stem from its unique atomic structure.

The Carbon-Fluorine Bond

The foundation of Teflon's performance is the bond between carbon and fluorine atoms. This is one of the strongest single bonds in organic chemistry.

These bonds create a protective, non-reactive "sheath" around the polymer's carbon backbone, effectively shielding it from outside forces.

Extreme Chemical Inertness

This molecular sheath makes Teflon non-reactive to nearly all chemicals, acids, and bases.

This is a stark contrast to plastics like ABS or polycarbonate, which can be damaged or dissolved by common industrial solvents.

Exceptional Thermal Stability

The strength of the carbon-fluorine bond also translates directly to high heat resistance.

Teflon can maintain its integrity at continuous service temperatures where many common plastics would melt or decompose. For example, certain grades can handle over 250°C (500°F).

Key Performance Differentiators in Practice

While the chemistry is the cause, the practical performance differences are what matter in application design. Teflon stands apart from other plastics in several critical ways.

Unmatched Non-Stick Surface

This is Teflon's most famous property. The fluorine atoms create a very low surface energy, meaning other substances have nothing to adhere to.

This quality is nearly impossible to replicate in other families of plastics and is essential for everything from cookware to industrial molds.

Extremely Low Coefficient of Friction

Often described as one of the "slipperiest" materials known, Teflon has an incredibly low coefficient of friction.

This makes it a premier choice for self-lubricating bearings, seals, and gland packing where reducing mechanical wear is critical.

Superior Electrical Insulation

Teflon is an excellent electrical insulator with a very high dielectric strength. It resists the flow of electricity exceptionally well.

This makes it indispensable for high-frequency electronics, cable insulation, and components where electrical leakage cannot be tolerated.

Weather and UV Resistance

Certain types of Teflon, such as FEP, exhibit outstanding resistance to weathering, UV radiation, and atmospheric pollutants.

This is a significant advantage over many plastics that become brittle and degrade with prolonged sun exposure.

Understanding the Trade-offs and Limitations

No material is perfect. Choosing Teflon means accepting a specific set of trade-offs compared to other engineering plastics.

Relative Softness and Low Mechanical Strength

Teflon is a relatively soft material. On the Shore D hardness scale, it scores significantly lower than engineering plastics like Nylon or PEEK.

It has lower tensile strength and is more susceptible to "creep" (deformation under load) and abrasion. It is not a good choice for high-load structural components.

Higher Material Cost

As a high-performance specialty polymer, Teflon is significantly more expensive than commodity plastics like polypropylene or PVC.

Its use is typically justified only when its unique properties are a strict requirement for the application's success.

Fabrication Challenges

Teflon's high melting point and chemical inertness make it more difficult to process.

Welding, bonding, or machining Teflon requires specialized techniques and equipment compared to more common thermoplastics.

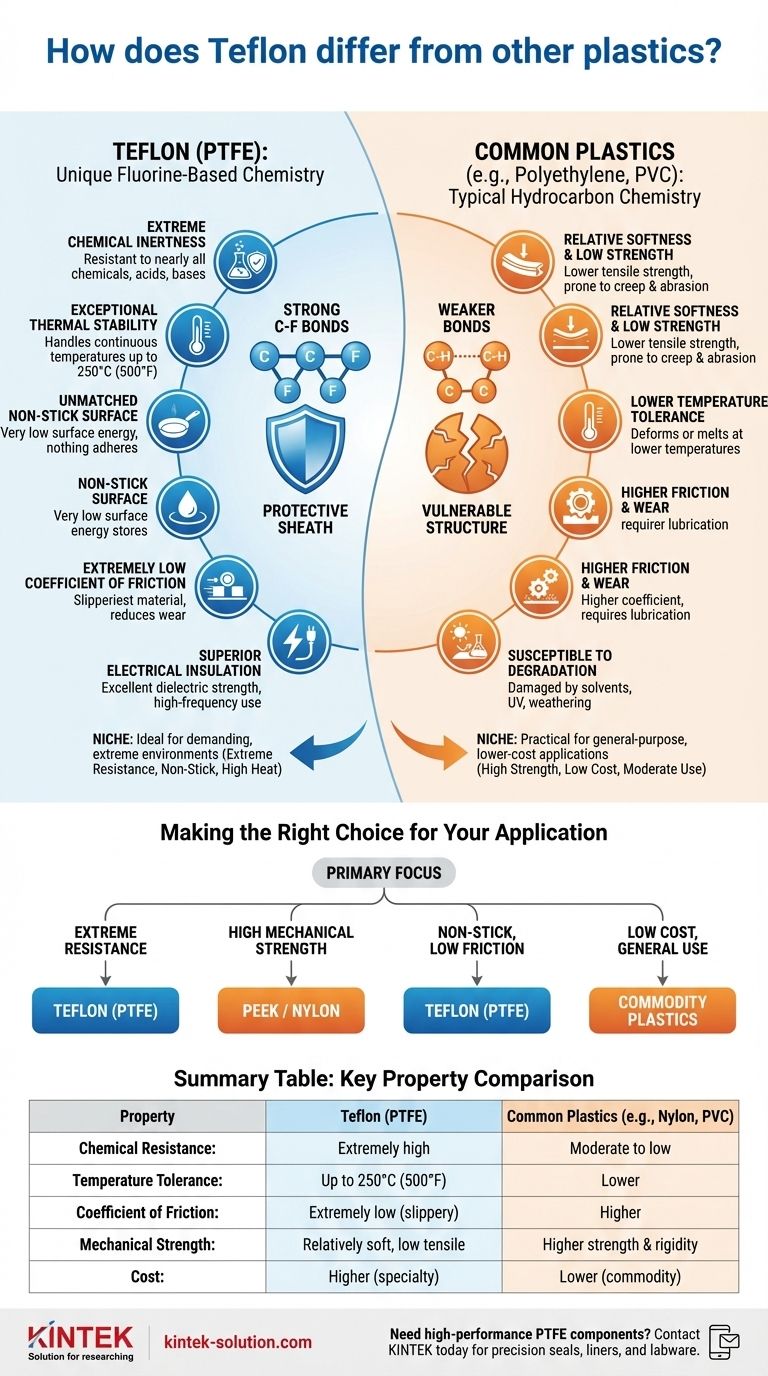

Making the Right Choice for Your Application

Your choice between Teflon and another plastic must be driven by the specific demands of your operating environment.

- If your primary focus is extreme chemical or heat resistance: Teflon is the default choice, as common plastics will likely fail.

- If your primary focus is high mechanical strength and rigidity: High-performance engineering plastics like PEEK or Nylon are often superior.

- If your primary focus is a non-stick, low-friction surface: Teflon's properties are nearly impossible to replicate with other plastics.

- If your primary focus is low cost for general-purpose use: Commodity plastics like polyethylene or polypropylene are far more practical.

Understanding these core differences allows you to move beyond a simple comparison and select the material truly engineered to solve your specific problem.

Summary Table:

| Property | Teflon (PTFE) | Common Plastics (e.g., Nylon, PVC) |

|---|---|---|

| Chemical Resistance | Extremely high; inert to most chemicals | Moderate to low; can be damaged by solvents |

| Temperature Tolerance | Up to 250°C (500°F) continuous | Lower; often deforms or melts at high temperatures |

| Coefficient of Friction | Extremely low (slippery) | Higher |

| Mechanical Strength | Relatively soft, low tensile strength | Higher strength and rigidity |

| Cost | Higher (specialty polymer) | Lower (commodity plastic) |

Need high-performance PTFE components that leverage Teflon's unique properties?

At KINTEK, we specialize in manufacturing precision PTFE components—including seals, liners, and custom labware—for demanding applications in the semiconductor, medical, laboratory, and industrial sectors. Whether you require prototypes or high-volume orders, our expertise in custom fabrication ensures your components meet the exacting standards required for extreme chemical, thermal, and non-stick applications.

Let us help you solve your most challenging material problems. Contact KINTEK today to discuss your project needs!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

- Custom PTFE Bottles for Diverse Industrial Applications

People Also Ask

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech