In short, Teflon is not an active sunscreen ingredient, but a supporting one that enhances the overall formulation. It improves the effectiveness of a sunscreen by acting as a film-former, creating a more stable, water-resistant, and uniform protective barrier on the skin. This allows the actual UV-blocking ingredients to do their job more effectively and for a longer duration.

The core function of Teflon, or Polytetrafluoroethylene (PTFE), in sunscreen is not to block UV rays itself. Instead, its chemical stability and resistance are used to reinforce the sunscreen's structure, making the final product more durable against water, sweat, and general wear.

The True Role of Teflon in Formulations

To understand Teflon's contribution, it's critical to see it as a performance-enhancing additive rather than a primary protective agent. Its benefits are indirect but significant.

It Is Not a UV Filter

First, let's be clear: Teflon (PTFE) does not absorb or reflect UV radiation. Unlike active ingredients like Zinc Oxide, Titanium Dioxide, or Avobenzone, it provides no direct sun protection on its own. Its value lies entirely in how it improves the behavior of the formula once applied to the skin.

Enhancing the Protective Film

A sunscreen's effectiveness depends on its ability to form a consistent, even film across the skin's surface. PTFE helps stabilize this film. Its inherent resistance to chemicals and degradation means it helps create a more robust matrix for the active UV filters to be suspended in.

Think of it as adding a flexible, water-resistant framework to the sunscreen layer, preventing it from breaking down or becoming uneven too quickly.

Improving Water and Wear Resistance

One of Teflon's most well-known properties is its durability and ability to repel water and oil. This is directly leveraged in sunscreen formulations.

By including PTFE, formulators can significantly boost a product's resistance to sweat and water. This makes the sunscreen last longer during physical activity or swimming, which is when reliable protection is most critical.

Key Properties and Considerations

While effective, the use of fluorinated polymers like PTFE is a specific formulation choice with its own context.

The Ingredient Name You'll See

On an ingredient list, you will not see the brand name "Teflon." Instead, you will find it listed by its chemical name: Polytetrafluoroethylene (PTFE). This is the inert, stable polymer used in the final product.

Durability is the Goal

The references to Teflon's use in industrial settings—lining pipes, coating wires, and resisting harsh chemicals—all highlight its core feature: extreme stability. This is the exact property formulators want to impart to the sunscreen film on your skin. It helps the product withstand environmental exposure beyond just UV light.

Environmental and Health Perspectives

The use of fluoropolymers in consumer products is a subject of public discussion. Much of the concern has historically been linked to chemicals used in the manufacturing process of PTFE (like PFOA), not the final, stable polymer itself. The PTFE used in cosmetics is considered inert and is not the same as these precursor chemicals.

Making the Right Choice for Your Goal

Understanding Teflon's role helps you interpret ingredient lists and choose a product that best suits your needs.

- If your primary focus is long-lasting, water-resistant protection: A sunscreen containing a film-former like PTFE can provide a more durable barrier, making it an excellent choice for sports, swimming, or humid conditions.

- If your primary focus is ingredient simplicity or avoiding specific compounds: You may prefer simpler mineral-based formulations or those that achieve water resistance through other means, such as natural waxes or silicones.

Ultimately, Teflon acts as a performance-enhancing support ingredient, designed to make the active sun-blocking agents in your product work more reliably.

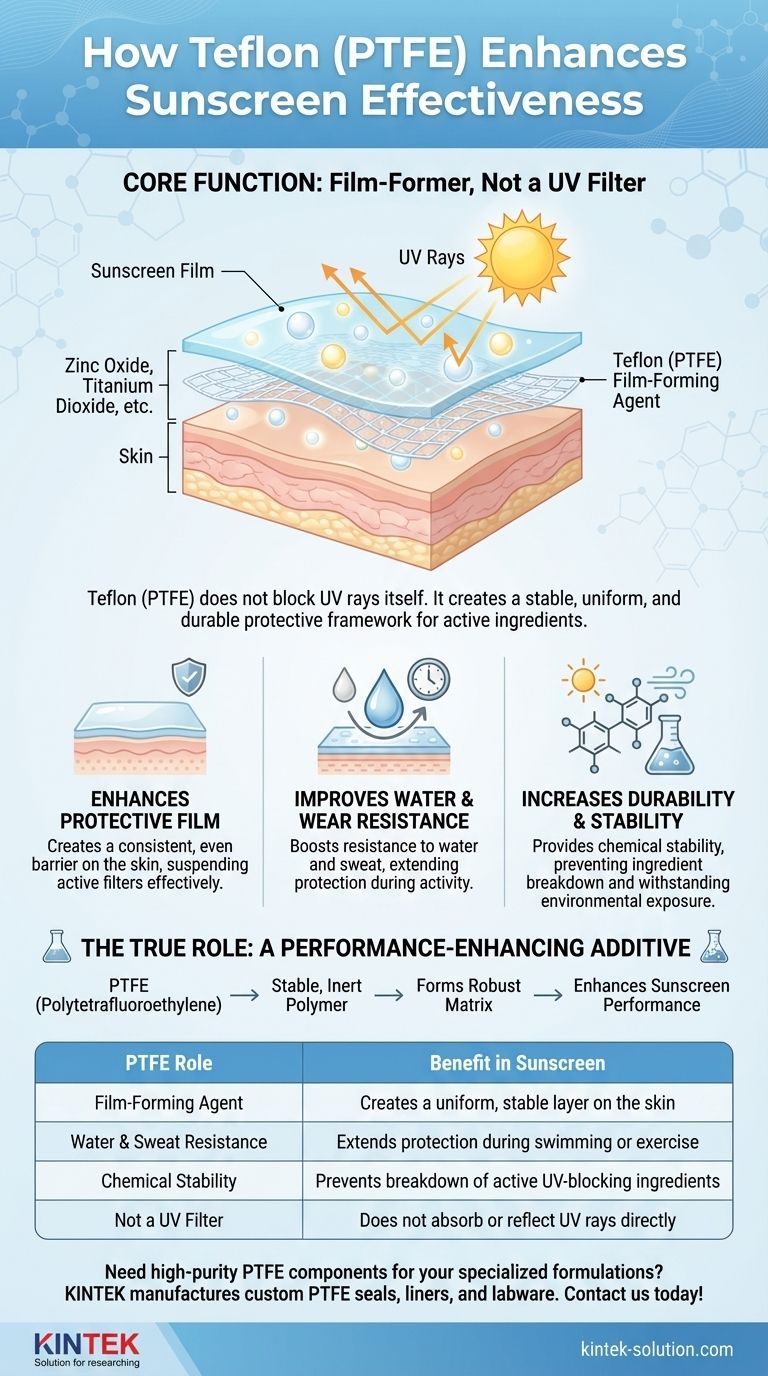

Summary Table:

| Teflon (PTFE) Role | Benefit in Sunscreen |

|---|---|

| Film-Forming Agent | Creates a uniform, stable layer on the skin |

| Water & Sweat Resistance | Extends protection during swimming or exercise |

| Chemical Stability | Prevents breakdown of active UV-blocking ingredients |

| Not a UV Filter | Does not absorb or reflect UV rays directly |

Need high-purity PTFE components for your specialized formulations? KINTEK manufactures custom PTFE seals, liners, and labware for the medical, laboratory, and industrial sectors. Our precision production ensures the chemical stability and performance your products demand. Contact us today to discuss your project from prototype to high-volume orders!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Bottles for Diverse Industrial Applications

People Also Ask

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments