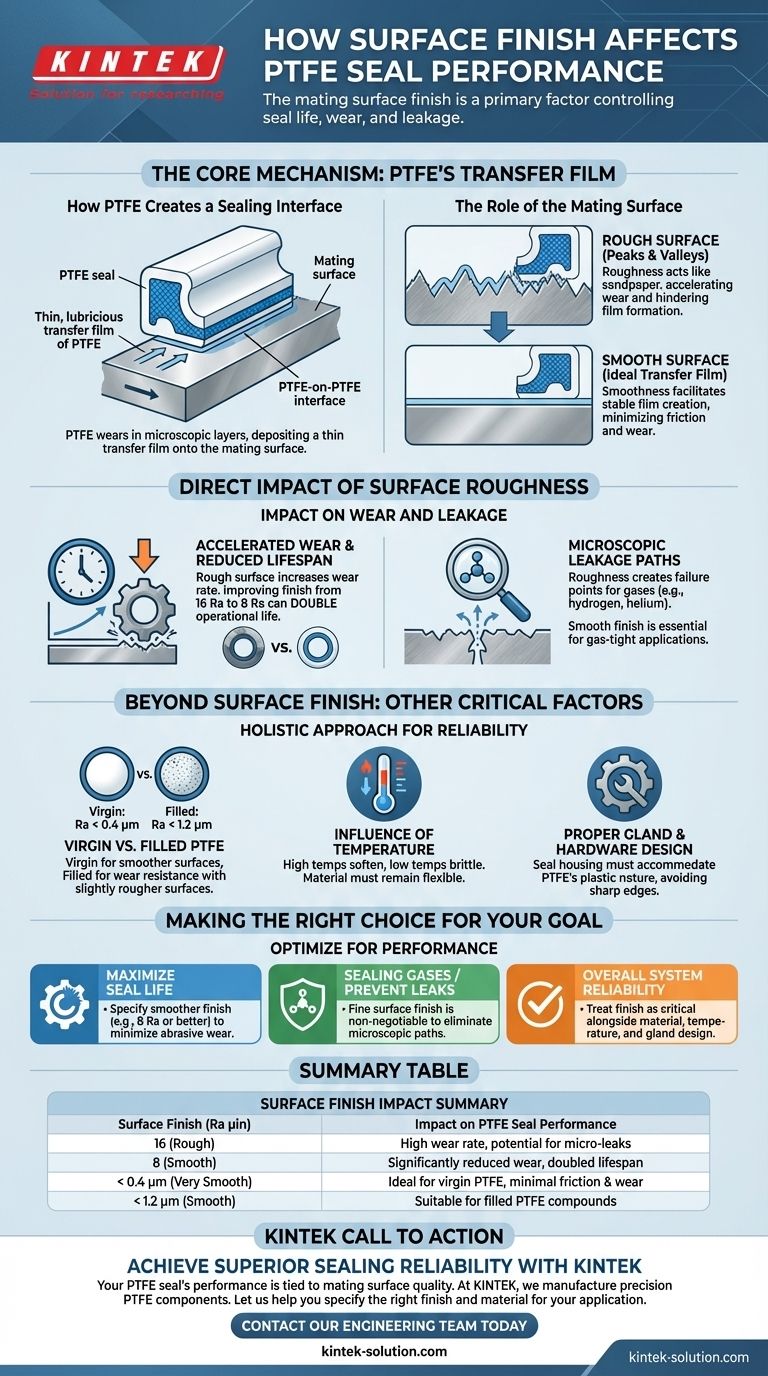

For any PTFE seal, the finish of the mating surface is not a minor detail—it is a primary factor controlling performance. A rough surface acts as an abrasive, dramatically accelerating wear and creating microscopic pathways for leaks. Improving the metal surface finish is one of the most effective ways to increase the lifespan and reliability of the entire sealing system.

The core principle is that PTFE seals work by depositing a thin, lubricious transfer film onto the mating surface. A smoother, properly prepared surface facilitates the creation of a stable film, which minimizes friction and wear, while a rough surface aggressively wears down the seal and compromises its integrity.

The Core Mechanism: PTFE's Transfer Film

Polytetrafluoroethylene (PTFE) has a unique interaction with the surfaces it seals against. Understanding this mechanism is key to specifying the correct surface finish.

How PTFE Creates a Sealing Interface

PTFE does not function like a typical elastomer. Instead, it wears in controlled, microscopic layers.

As the seal operates, it deposits a very thin coating of its own material onto the dynamic mating surface. This transfer film creates an ideal, low-friction interface of PTFE running on PTFE.

The Role of the Mating Surface

The initial state of the metal surface dictates how effectively this transfer film can form.

A rough surface has microscopic peaks and valleys. The initial operation of the seal involves the PTFE being worn away to fill these valleys, a process that consumes the seal material and shortens its life.

The Direct Impact of Surface Roughness

The texture of the hardware has two direct and critical consequences for the seal: how long it lasts and how well it prevents leaks.

Accelerated Wear and Reduced Lifespan

A rough surface acts like fine-grit sandpaper, continuously abrading the seal. This significantly increases the wear rate.

The effect is dramatic. For example, simply improving a metal finish from a rough 16 Ra (μin) to a smoother 8 Ra (μin) can double the operational life of a PTFE seal.

Microscopic Leakage Paths

Surface roughness creates a network of tiny channels at the sealing interface. While these may not be an issue for viscous liquids, they are critical failure points for sealing gases.

Small gas molecules, like hydrogen or helium, can easily travel through these microscopic leakage paths, making a smooth finish essential for gas-tight applications.

Beyond Surface Finish: Other Critical Factors

While surface finish is paramount, it works in concert with other design and material considerations. A holistic approach is necessary for true sealing reliability.

Virgin vs. Filled PTFE Compounds

The type of PTFE material also plays a role. Virgin PTFE is softer and can accommodate a very smooth surface finish, often specified as Ra < 0.4 μm (16 μin).

Adding fillers like glass or carbon improves wear resistance and mechanical properties but results in a harder material. These filled PTFE compounds are typically paired with slightly rougher surfaces, around Ra < 1.2 μm (47 μin).

The Influence of Temperature

Temperature has a profound impact on PTFE's mechanical properties. High temperatures can cause the material to soften, reducing its effectiveness.

Conversely, very low temperatures can cause it to harden and become brittle, risking cracks. The material must remain flexible enough to handle thermal expansion and contraction of the hardware.

Proper Gland and Hardware Design

The physical design of the seal housing is also critical. PTFE is a plastic, not a highly elastic rubber.

Gland designs must accommodate this nature. Forcing a seal into a complex, sharp-edged cavity can cause damage during installation, leading to immediate failure regardless of the surface finish.

Making the Right Choice for Your Goal

Optimizing your surface finish specification is a direct investment in the performance and longevity of your equipment.

- If your primary focus is maximizing seal life: Specify a smoother mating surface finish (e.g., 8 Ra μin or better) to minimize abrasive wear from the very beginning.

- If your primary focus is sealing gases or preventing micro-leaks: A fine surface finish is non-negotiable to eliminate the microscopic leakage paths inherent in rougher textures.

- If your primary focus is overall system reliability: Treat surface finish as a critical parameter alongside material selection (PTFE compound), operating temperature, and proper gland design.

Ultimately, controlling the surface finish is one of the most powerful levers you have for achieving predictable, long-term sealing performance.

Summary Table:

| Surface Finish (Ra μin) | Impact on PTFE Seal Performance |

|---|---|

| 16 (Rough) | High wear rate, potential for micro-leaks |

| 8 (Smooth) | Significantly reduced wear, doubled lifespan |

| < 0.4 μm (Very Smooth) | Ideal for virgin PTFE, minimal friction and wear |

| < 1.2 μm (Smooth) | Suitable for filled PTFE compounds |

Achieve superior sealing reliability with KINTEK.

Your PTFE seal's performance is directly tied to the quality of the mating surface. At KINTEK, we manufacture precision PTFE components—including seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors. We understand that a smooth, properly prepared surface is critical for forming a stable transfer film, minimizing wear, and preventing leaks.

Whether you need custom prototypes or high-volume orders, our expertise ensures your seals perform reliably under demanding conditions. Let us help you specify the right surface finish and PTFE material for your application.

Contact our engineering team today for a consultation and see how our precision manufacturing can extend the life and enhance the performance of your sealing systems.

Visual Guide

Related Products

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What are the key properties of PTFE that make it suitable for sealing applications? | High-Performance Seals for Extreme Conditions

- Why are PTFE seals preferred over traditional rubber seals? Superior Performance in Extreme Conditions

- What are the five outstanding characteristics of PTFE seals? Engineered for Extreme Performance

- What are the main chemical resistance properties of PTFE-coated O-rings? Uncover the True Role of the Coating

- What makes PTFE stand out among materials used in sealing technology? Unmatched Chemical & Thermal Resistance