In wire and cable design, PTFE's non-stick property is one of its most critical engineering advantages. This characteristic, technically known as a low coefficient of friction, allows individual wires and internal components within a cable to slide past one another with minimal resistance. This directly enables the creation of more compact, flexible, and durable cable assemblies that are easier to install.

The true benefit of PTFE's "non-stick" surface is not just that components don't adhere to each other; it's that this low-friction environment fundamentally changes what is possible in cable design, unlocking higher density, superior flexibility, and greater long-term reliability.

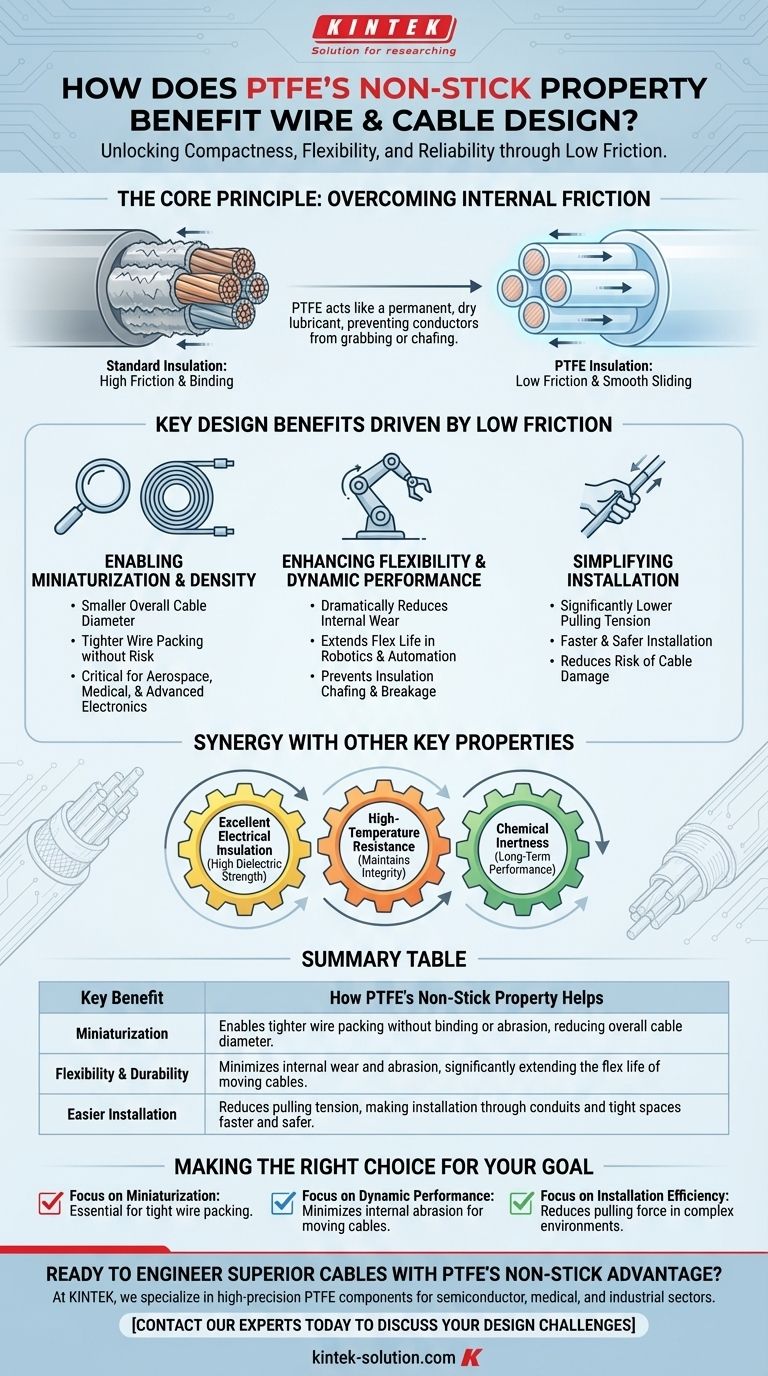

The Core Principle: Overcoming Internal Friction

At the heart of any multi-conductor cable is a challenge: managing the interaction between its components. As a cable bends or is pulled, the internal wires must move relative to each other.

What "Non-Stick" Means in Engineering Terms

The term "non-stick" refers to PTFE's exceptionally low coefficient of friction. This means that surfaces coated in or made from PTFE require very little force to slide past one another.

In a cable, this property prevents conductors from binding, grabbing, or chafing against each other, ensuring smooth movement.

How Low Friction Works Inside a Cable

Imagine the individual wires inside a cable bundle. Without a low-friction insulator, these wires can create significant drag against each other, especially in tight bends or during installation.

PTFE's non-stick surface acts like a permanent, dry lubricant on every single conductor. This allows the wires to adjust their position effortlessly, reducing internal stress on the entire assembly.

Key Design Benefits Driven by Low Friction

This single property translates into several distinct, practical advantages for engineers and installers.

Enabling Miniaturization and Density

Because PTFE-insulated wires slide easily, they can be packed together much more tightly without the risk of binding or abrasion.

This allows for a smaller overall cable diameter for the same conductor count, a critical factor in applications where space is at a premium, such as in aerospace, medical devices, and advanced electronics.

Enhancing Flexibility and Dynamic Performance

In applications requiring repeated movement, such as robotics or automation, internal friction is a primary cause of failure. The friction between conductors leads to insulation wear, chafing, and eventual breakage.

PTFE's non-stick nature dramatically reduces this internal wear, extending the flex life and overall durability of the cable.

Simplifying Installation

Pulling cable through long runs of conduit or tight, complex pathways creates immense friction. A high-friction cable jacket or internal structure can make installation difficult or even impossible without damaging the cable.

Cables with PTFE components have significantly lower pulling tension, making installation faster, easier, and safer for the integrity of the conductors.

Understanding the Trade-offs

While its low-friction property is powerful, PTFE is not the default choice for every application. Its benefits must be weighed against practical considerations.

Synergy with Other Key Properties

The non-stick characteristic does not work in isolation. Its value is amplified by PTFE's other exceptional properties, which allow engineers to fully leverage the low-friction design.

- Excellent Electrical Insulation: PTFE's high dielectric strength prevents electrical shorting even when wires are packed into a dense, compact bundle.

- High-Temperature Resistance: Dense cable assemblies can generate significant heat. PTFE's ability to withstand high temperatures ensures it maintains its structural and electrical integrity.

- Chemical Inertness: PTFE's non-reactive nature ensures that its low-friction surface will not degrade when exposed to oils, fuels, or other harsh chemicals, guaranteeing long-term performance.

Material Cost and Processing

PTFE is a premium polymer, and its material cost is higher than that of common insulators like PVC or Polyethylene.

Furthermore, processing PTFE into finished wire and cable requires specialized equipment and techniques, which can add to the final product's cost. The decision to use PTFE is therefore an investment in performance and reliability.

Making the Right Choice for Your Goal

Selecting an insulation material requires aligning its properties with your primary engineering objective.

- If your primary focus is miniaturization and high-density routing: PTFE's low friction is essential, as it allows for the tightest possible wire packing without compromising integrity.

- If your primary focus is dynamic performance and high-flex life: PTFE's non-stick nature minimizes internal abrasion, which is the leading cause of failure in moving cables.

- If your primary focus is installation efficiency in complex environments: Low-friction PTFE cables significantly reduce the pulling force required, saving time and preventing costly damage.

Ultimately, understanding how PTFE's non-stick property reduces internal friction empowers you to design and specify cables that are not only smaller and more flexible but also fundamentally more robust.

Summary Table:

| Key Benefit | How PTFE's Non-Stick Property Helps |

|---|---|

| Miniaturization | Enables tighter wire packing without binding or abrasion, reducing overall cable diameter. |

| Flexibility & Durability | Minimizes internal wear and abrasion, significantly extending the flex life of moving cables. |

| Easier Installation | Reduces pulling tension, making installation through conduits and tight spaces faster and safer. |

Ready to engineer superior cables with PTFE's non-stick advantage?

At KINTEK, we specialize in manufacturing high-precision PTFE components, including custom wire insulation and cable liners, for the semiconductor, medical, laboratory, and industrial sectors. Our expertise in custom fabrication—from prototypes to high-volume orders—ensures your designs achieve maximum density, flexibility, and reliability.

Contact our experts today to discuss how our PTFE solutions can solve your most challenging wire and cable design problems.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What are the main applications of PTFE type Teflon? Unlock Its Versatility for Your Industry

- What finishing techniques are effective for machined Teflon parts? Achieve Functional Performance and Dimensional Stability

- What factors should be considered when choosing between Nylon and PTFE? Select the Right Material for Your Application

- What industrial benefits do PTFE-machined parts offer? Achieve Peak Performance in Demanding Applications

- What fabrication services are available for PTFE? Shearing, Stamping, Laser Cutting, Molding & Machining