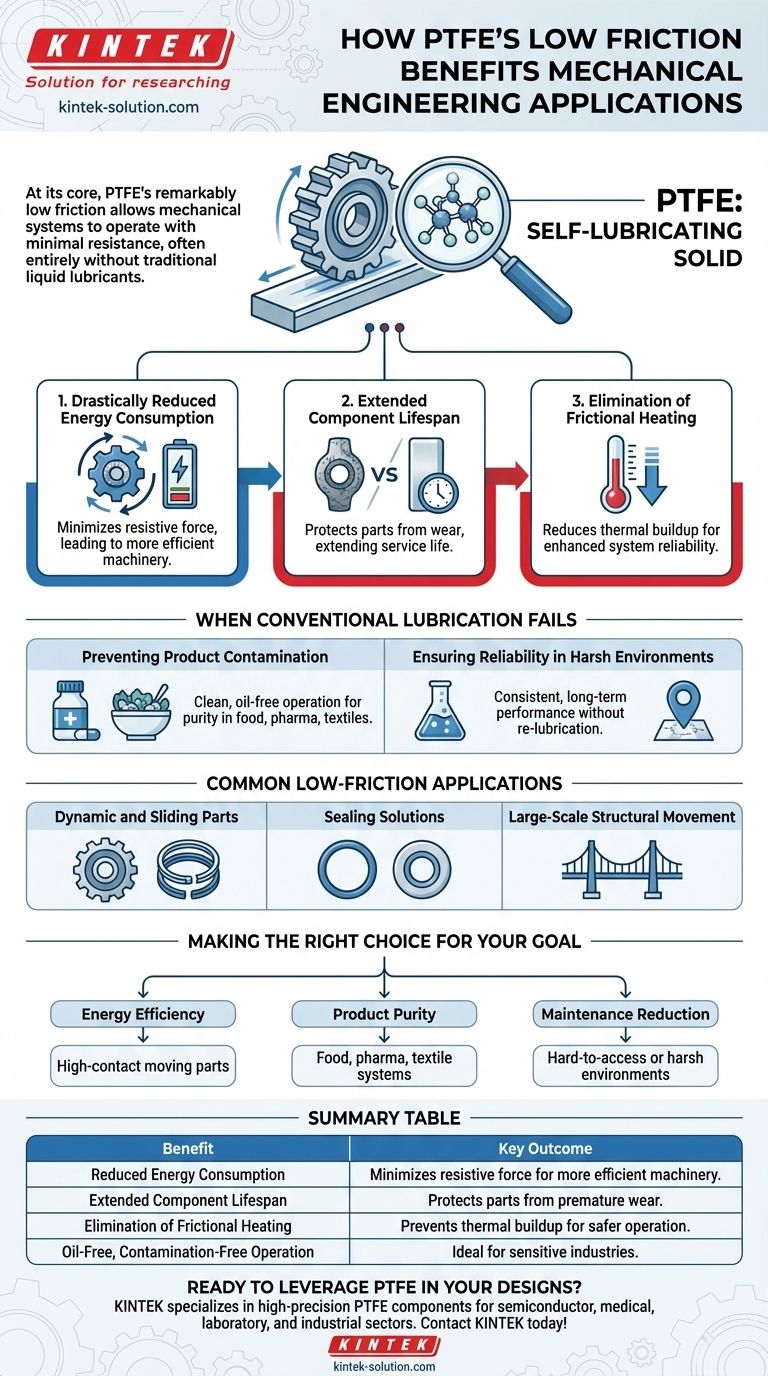

At its core, PTFE's remarkably low friction allows mechanical systems to operate with minimal resistance, often entirely without traditional liquid lubricants. This property directly translates into reduced energy consumption, significantly less wear on components, and a longer operational lifespan for machinery across numerous industries.

The primary benefit of PTFE's low friction is its ability to function as a self-lubricating solid. This quality solves the fundamental engineering challenge of reducing friction in environments where conventional lubricants like oil or grease are impractical, undesirable, or simply impossible to use.

The Pillars of PTFE's Low-Friction Advantage

The benefits of PTFE's low coefficient of friction—the lowest of any known solid material—can be understood through three primary outcomes for mechanical systems.

1. Drastically Reduced Energy Consumption

In any dynamic system, energy is consumed to overcome friction between moving parts.

PTFE's inherent slipperiness minimizes this resistive force. This means less energy is wasted, leading to more efficient machinery, whether in automotive, manufacturing, or aerospace applications.

2. Extended Component Lifespan

Friction is a direct cause of wear and tear. Over time, it degrades the surfaces of moving components, leading to failure.

By minimizing friction, PTFE protects parts like bearings, gears, and piston rings from premature wear. This extends the service life of both the individual component and the entire assembly.

3. Elimination of Frictional Heating

The movement of parts against each other generates heat, which can compromise material integrity and performance, especially in sealing applications.

PTFE's low friction reduces this potential for thermal buildup. This ensures that seals maintain their intended properties and components operate within safe temperature ranges, enhancing overall system reliability.

When Conventional Lubrication Fails

The most critical applications for PTFE are those where traditional lubrication is not an option. Its self-lubricating nature provides a clean, built-in solution that fundamentally changes design possibilities.

Preventing Product Contamination

In industries like pharmaceuticals, food processing, and textiles, any contamination from oils or greases can ruin a product batch.

PTFE components, such as bearings and slide plates, operate cleanly without external lubricants, ensuring product purity.

Ensuring Reliability in Harsh Environments

Some mechanical systems operate where lubricants would dissolve in solvents or where parts are too inaccessible for regular maintenance.

PTFE provides a "fit and forget" solution, offering consistent, long-term performance without the need for re-lubrication.

Enabling Oil-Free Designs

The ability to design oil-free mechanical parts is a significant advantage. This is crucial for machine tool rails, guide rings, and other parts that require smooth, repeatable motion without the mess and complexity of lubrication systems.

Common Low-Friction Applications

PTFE's unique properties make it a versatile material for a wide range of mechanical components that rely on sliding action.

Dynamic and Sliding Parts

The most common use is for parts that slide against each other. This includes slide bearings, gears, piston rings, and machine tool guides, where low friction is paramount for performance.

Sealing Solutions

In dynamic seals, PTFE O-rings and washers reduce rotational friction, which lowers wear and improves the efficiency and longevity of the seal.

Large-Scale Structural Movement

In civil engineering, PTFE is used in sliding blocks and support plates for bridges, tunnels, and large pipelines. This allows massive structures to expand, contract, or move slightly without creating destructive stress.

Making the Right Choice for Your Goal

The decision to use PTFE should be driven by the specific problem you are trying to solve.

- If your primary focus is energy efficiency: Use PTFE in high-contact moving parts like bearings and gears to minimize the power lost to friction.

- If your primary focus is product purity: Implement PTFE components in systems for food, pharmaceutical, or textile manufacturing where lubricant contamination is unacceptable.

- If your primary focus is maintenance reduction: Choose PTFE components for hard-to-access mechanical systems or those operating in harsh chemical environments that degrade traditional lubricants.

By understanding its self-lubricating nature, you can leverage PTFE to design more efficient, reliable, and longer-lasting mechanical systems.

Summary Table:

| Benefit | Key Outcome |

|---|---|

| Reduced Energy Consumption | Minimizes resistive force for more efficient machinery. |

| Extended Component Lifespan | Protects parts like bearings and gears from premature wear. |

| Elimination of Frictional Heating | Prevents thermal buildup for safer, more reliable operation. |

| Oil-Free, Contamination-Free Operation | Ideal for food, pharmaceutical, and chemical industries. |

Ready to leverage PTFE's low friction in your designs? KINTEK specializes in manufacturing high-precision PTFE components—including seals, liners, and custom labware—for the semiconductor, medical, laboratory, and industrial sectors. Whether you need prototypes or high-volume orders, our expertise ensures your mechanical systems achieve peak efficiency and reliability. Contact KINTEK today to discuss your project requirements!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers