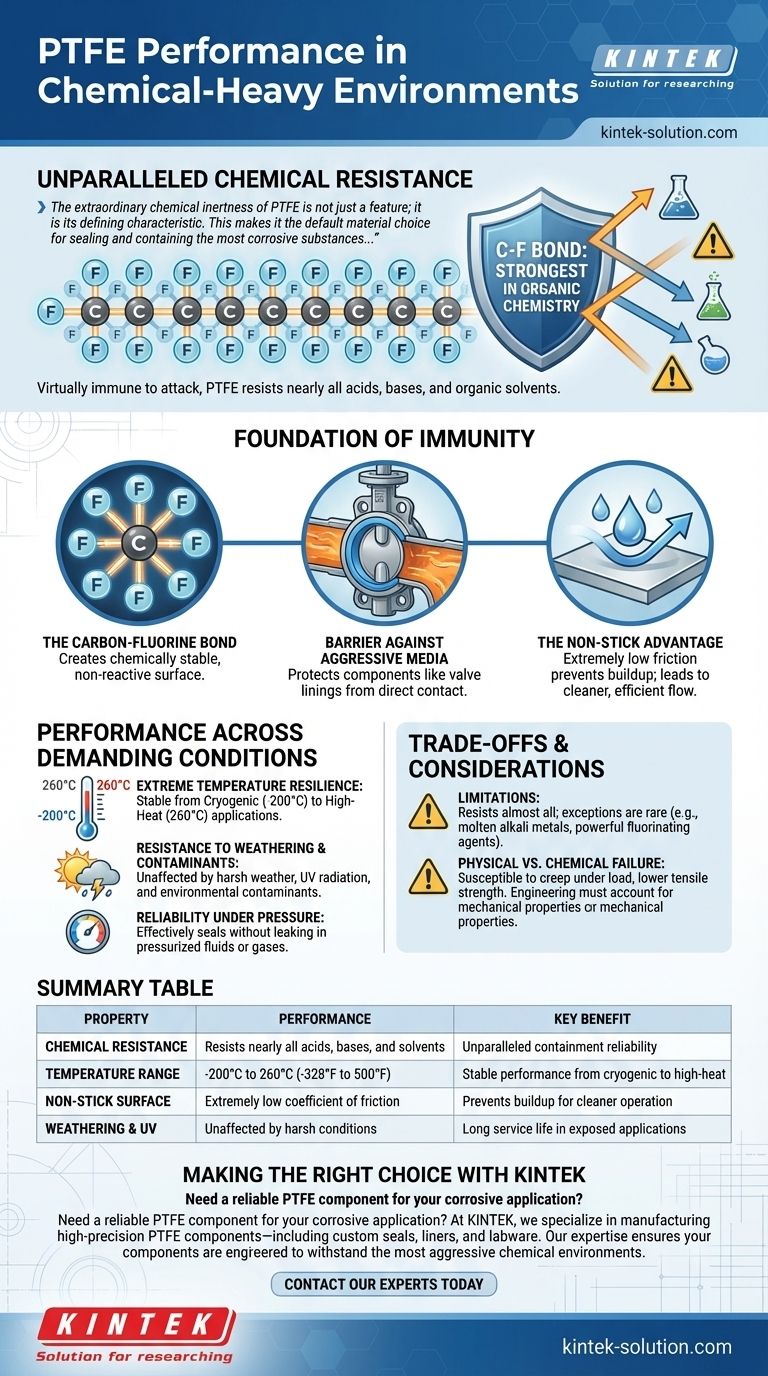

In short, PTFE's performance is nearly unparalleled. Polytetrafluoroethylene (PTFE) is virtually immune to chemical attack, making it one of the most reliable materials for use in corrosive, chemical-heavy environments. Its unique molecular structure allows it to resist nearly all acids, bases, and organic solvents without degrading.

The extraordinary chemical inertness of PTFE is not just a feature; it is its defining characteristic. This makes it the default material choice for sealing and containing the most corrosive substances where failure is not an option.

The Foundation of PTFE's Chemical Immunity

To understand PTFE's performance, we must first look at its molecular structure. Its resilience is not an accident but a direct result of its chemistry.

The Carbon-Fluorine Bond

At its core, PTFE consists of a long chain of carbon atoms completely shielded by fluorine atoms. The carbon-fluorine (C-F) bond is one of the strongest single bonds in organic chemistry.

This powerful bond creates a chemically stable and non-reactive surface. It effectively forms a protective shell around the carbon backbone, preventing aggressive chemicals from finding a point of attack.

A Barrier Against Aggressive Media

This chemical inertness makes PTFE an ideal barrier material. When used as a lining in components like butterfly valves, it protects metal parts from direct contact with corrosive fluids.

This protection allows systems to handle aggressive substances that would quickly damage or destroy less robust materials.

The Non-Stick Advantage

A direct consequence of its chemical non-reactivity is PTFE's extremely low coefficient of friction. Its surface is exceptionally smooth and non-stick.

In chemical processing, this prevents materials from adhering to valve and pipe surfaces, leading to cleaner, more efficient operation and flow.

Performance Across Demanding Conditions

Chemical resistance is only part of the equation in industrial environments. PTFE's ability to maintain its integrity under a wide range of physical stressors is what makes it truly valuable.

Extreme Temperature Resilience

PTFE exhibits remarkable thermal stability. It maintains its shape and chemical resistance across an operational range of -200°C to 260°C (-328°F to 500°F).

This makes it suitable for both cryogenic applications and high-temperature systems involving steam or high-powered engines.

Resistance to Weathering and Contaminants

The material is unaffected by harsh weather conditions, UV radiation, or environmental contaminants. This ensures a long shelf life and reliable performance in exposed applications without degradation.

Reliability Under Pressure

When used in seals and gaskets, PTFE effectively seals mating surfaces without leaking, even when exposed to pressurized fluids or gases. Its durability ensures a long-term, reliable seal, minimizing the need for frequent replacement.

Understanding the Trade-offs and Considerations

While PTFE's chemical resistance is exceptional, no material is without its practical limitations. True expertise requires understanding the full context.

What "Virtually Immune" Means

PTFE resists almost every known chemical. The exceptions are extremely rare and highly specific, such as molten alkali metals and certain powerful fluorinating agents. For the vast majority of industrial applications, it is considered completely inert.

Physical vs. Chemical Failure

In most applications, the limiting factor for PTFE is not its chemical resistance but its physical properties. It can be susceptible to creep (cold flow) under sustained load and has lower tensile strength compared to metals.

Therefore, engineering design must account for these mechanical properties to prevent physical failure, even though the material remains chemically intact.

Making the Right Choice for Your Application

Selecting a material requires matching its strengths to your primary operational goal.

- If your primary focus is absolute chemical containment: PTFE's near-total inertness makes it the most reliable choice for gaskets, seals, and linings that will be exposed to aggressive media.

- If your primary focus is performance across extreme temperatures: Its exceptionally wide operational temperature range ensures stability and chemical resistance in both cryogenic and high-heat processes.

- If your primary focus is long-term reliability and low maintenance: PTFE's resistance to degradation from chemicals, pressure, and weathering minimizes replacement frequency and ensures operational consistency.

Ultimately, selecting PTFE is a decision to prioritize chemical resilience and long-term operational integrity.

Summary Table:

| Property | Performance | Key Benefit |

|---|---|---|

| Chemical Resistance | Resists nearly all acids, bases, and solvents | Unparalleled containment reliability |

| Temperature Range | -200°C to 260°C (-328°F to 500°F) | Stable performance from cryogenic to high-heat |

| Non-Stick Surface | Extremely low coefficient of friction | Prevents buildup for cleaner operation |

| Weathering & UV | Unaffected by harsh conditions | Long service life in exposed applications |

Need a reliable PTFE component for your corrosive application?

At KINTEK, we specialize in manufacturing high-precision PTFE components—including custom seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors. Our expertise ensures your components are engineered to withstand the most aggressive chemical environments while maintaining integrity.

Contact our experts today to discuss your custom fabrication needs, from prototypes to high-volume orders.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

People Also Ask

- What are the base characteristics of PTFE? Unlocking Extreme Performance in Friction, Temperature, and Chemical Resistance

- How does PTFE perform in wet or oil-containing environments? Unmatched Hydrophobic & Oleophobic Reliability

- What is expanded PTFE and what are its key properties? A Guide to the Microporous Wonder Material

- What quality control measures are used in PTFE production? Ensure Material Integrity for Your Application

- How does PTFE contribute to semiconductor manufacturing? Ensure Purity and Prevent Contamination

- What are the common types of filled PTFE and their properties? Enhance Performance for Demanding Applications

- What are the advantages of using Teflon coating in cooking utensils? Discover Effortless Cooking & Cleaning

- What are the key chemical properties of PTFE that make it useful for cookware? Unlock Superior Non-Stick Performance