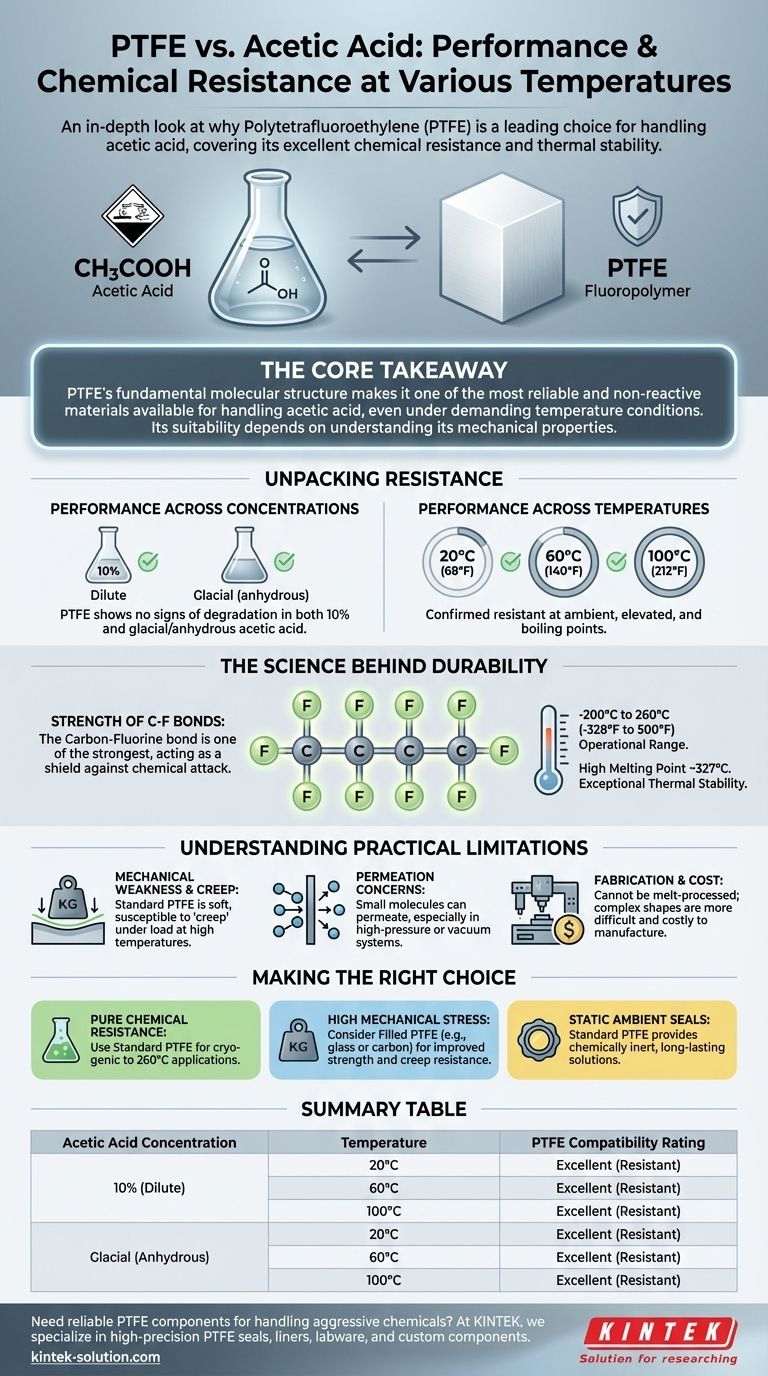

To put it simply, PTFE (Polytetrafluoroethylene) demonstrates excellent chemical resistance to acetic acid across a wide range of common operational temperatures and concentrations. Based on compatibility data, it is rated as resistant to both 10% and glacial (anhydrous) acetic acid at temperatures of 20°C (68°F), 60°C (140°F), and 100°C (212°F). This robust performance stems from the material's inherent chemical inertness and exceptional thermal stability.

The core takeaway is that PTFE's fundamental molecular structure makes it one of the most reliable and non-reactive materials available for handling acetic acid, even under demanding temperature conditions. Its suitability, however, depends on understanding its mechanical properties, not just its chemical resistance.

Unpacking PTFE's Resistance to Acetic Acid

The reliability of PTFE in acetic acid service is not a marginal pass but a definitive one. This performance holds true regardless of the acid's concentration, from dilute solutions to its pure, glacial form.

Performance Across Concentrations

PTFE shows no signs of degradation when exposed to either dilute (10%) acetic acid or glacial/anhydrous acetic acid. This indicates that the presence of water in the solution does not alter its fundamental compatibility.

Performance Across Temperatures

The material is confirmed to be resistant at key temperature benchmarks: 20°C, 60°C, and 100°C. This covers a significant range for many laboratory and industrial processes, from ambient conditions to the boiling point of water.

The Science Behind PTFE's Durability

PTFE's resilience is not accidental; it is a direct result of its unique molecular structure and the incredible strength of its chemical bonds. This is why it outperforms many other polymers in aggressive environments.

The Strength of Carbon-Fluorine Bonds

The backbone of PTFE is a chain of carbon atoms completely sheathed by fluorine atoms. The carbon-fluorine (C-F) bond is one of the strongest single bonds in organic chemistry, making the molecule exceptionally stable and non-reactive.

This powerful bond acts as a shield, preventing chemicals like acetic acid from attacking and breaking down the polymer chain.

Exceptional Thermal Stability

PTFE is renowned for its performance at extreme temperatures. Its practical operational range is vast, typically cited from -200°C (-328°F) up to 260°C (500°F).

The material’s high melting point of approximately 327°C (621°F) ensures it remains solid and stable well beyond the temperatures tested with acetic acid. This makes it a safe choice for applications involving heat cycling.

Understanding the Practical Limitations

While its chemical and thermal resistance is world-class, PTFE is not without trade-offs. Its mechanical properties are a critical consideration for any engineering application.

Mechanical Weakness and Creep

Standard, unfilled PTFE is a relatively soft material. Under sustained load, especially at elevated temperatures, it is susceptible to "creep" or cold flow, where the material slowly deforms over time.

This is a critical factor when designing components like seals, gaskets, or valve seats that are under constant mechanical stress.

Permeation Concerns

While PTFE does not react with chemicals, it is not completely impervious. Very small molecules can sometimes slowly permeate or pass through the polymer matrix, especially in gas or high-pressure applications.

For most acetic acid liquid applications, this is not a concern. However, in high-purity or vacuum systems, it is a factor to evaluate.

Fabrication and Cost

PTFE cannot be processed using conventional melt-processing techniques like injection molding, which can make manufacturing complex shapes more difficult and costly compared to other polymers.

Making the Right Choice for Your Application

Selecting the right material requires balancing chemical resistance with the mechanical and environmental demands of your system.

- If your primary focus is pure chemical and thermal resistance: PTFE is an industry-standard choice for handling acetic acid, offering unparalleled reliability from cryogenic temperatures up to 260°C.

- If your application involves high mechanical stress or pressure: Consider using a filled grade of PTFE (e.g., glass- or carbon-filled) to significantly improve its strength and resistance to creep.

- If you are designing a static seal for ambient conditions: Standard PTFE provides a chemically inert and long-lasting solution that will not degrade from exposure to acetic acid or weathering.

By understanding both its exceptional chemical inertness and its physical limitations, you can confidently specify PTFE for the right applications.

Summary Table:

| Acetic Acid Concentration | Temperature | PTFE Compatibility Rating |

|---|---|---|

| 10% (Dilute) | 20°C (68°F) | Excellent (Resistant) |

| 10% (Dilute) | 60°C (140°F) | Excellent (Resistant) |

| 10% (Dilute) | 100°C (212°F) | Excellent (Resistant) |

| Glacial (Anhydrous) | 20°C (68°F) | Excellent (Resistant) |

| Glacial (Anhydrous) | 60°C (140°F) | Excellent (Resistant) |

| Glacial (Anhydrous) | 100°C (212°F) | Excellent (Resistant) |

Need reliable PTFE components for handling aggressive chemicals like acetic acid?

At KINTEK, we specialize in manufacturing high-precision PTFE seals, liners, labware, and custom components for the semiconductor, medical, laboratory, and industrial sectors. Our expertise ensures your equipment operates safely and efficiently, even under demanding thermal and chemical conditions.

We offer custom fabrication from prototypes to high-volume orders, tailoring solutions to your specific mechanical and chemical requirements.

Contact us today to discuss your application and get a quote for durable, chemically inert PTFE components!

Visual Guide

Related Products

- Custom PTFE Bottles for Diverse Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

People Also Ask

- What are the main advantages of PTFE as a material for laboratory bottles? Superior Chemical & Thermal Resistance

- What are the key applications of the PTFE bottle? Ensure Chemical Safety and Sample Purity

- What is the molecular structure of PTFE? The Key to Its Unmatched Chemical & Thermal Resistance

- What are the temperature limits for the PTFE bottle? Ensure Safety from -200°C to 260°C

- What is PTFE and what class of plastics does it belong to? A Guide to High-Performance Fluoropolymers