PTFE paste extrusion is a multi-step manufacturing process that transforms fine Polytetrafluoroethylene (PTFE) powder into high-strength, continuous products like tubing and wire insulation. It achieves this by mixing the powder with a lubricant to form a paste, extruding this paste under pressure at low temperatures, and then using a two-stage heat treatment to remove the lubricant and fuse the material into a solid, durable final form.

The core challenge with PTFE is its extremely high melt viscosity, which prevents it from being processed like conventional plastics. Paste extrusion overcomes this by using a lubricant as a processing aid, allowing the material to be shaped at low temperatures while creating a strong, fibrous internal structure that delivers superior performance.

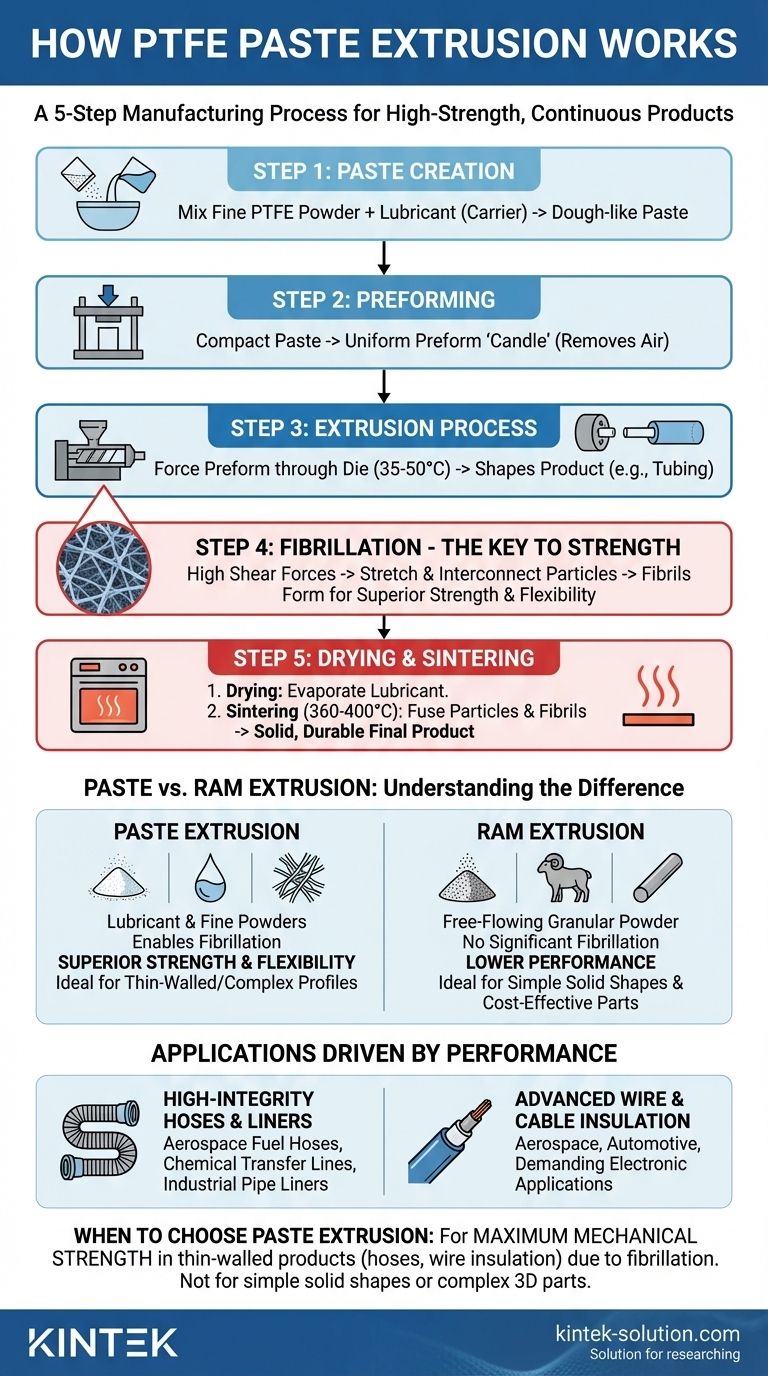

The Core Mechanism: From Powder to Product

Understanding the paste extrusion process is best done by breaking it down into its distinct, sequential stages. Each step serves a critical function in developing the final material properties.

Step 1: Creating the Paste

The process begins by mixing a very fine PTFE powder with a volatile lubricant, typically a mineral spirit or naphtha-based solvent. This creates a cohesive, dough-like paste. The lubricant’s sole purpose is to act as a carrier and processing aid, enabling the powder particles to flow under pressure.

Step 2: Forming the Preform

This paste is then compacted under pressure into a dense, cylindrical shape known as a preform or "candle." This step removes trapped air and creates a uniform billet of material that is ready for the extruder.

Step 3: The Extrusion Process

The preform is loaded into an extruder and forced through a shaped die at high pressure. Unlike melt extrusion for other plastics, this occurs at a relatively low temperature, typically between 35-50°C (95-122°F). The die dictates the final shape of the extrudate, such as a thin-walled tube or a coating over a wire.

Step 4: Fibrillation - The Key to Strength

This is the most critical stage for the material's final properties. As the lubricated particles are forced through the die, the high shear forces cause them to stretch and interconnect, forming a strong, microscopic network of fibers called fibrils. This fibrillation is what gives paste-extruded PTFE its exceptional tensile strength and flexibility.

Step 5: Drying and Sintering

After extrusion, the product undergoes a two-part thermal process. First, it is gently heated in a drying oven to evaporate the volatile lubricant.

Next, the dried product is heated to a much higher temperature of 360-400°C (680-752°F) in a process called sintering. This temperature is above PTFE's melting point, causing the individual particles and fibrils to fuse together into a solid, non-porous, and uniform material.

Understanding the Trade-offs: Paste vs. Ram Extrusion

It is crucial to distinguish PTFE paste extrusion from another method, PTFE ram extrusion, as they serve different purposes and produce different results.

Paste Extrusion's Profile

Paste extrusion relies on the lubricant and fine powders to enable the fibrillation process. This makes it ideal for producing high-strength, thin-walled, or complex continuous profiles where mechanical performance is paramount.

Ram Extrusion's Profile

Ram extrusion uses a free-flowing (granular) PTFE powder without a lubricant. A ram cyclically compacts small amounts of powder and pushes the profile through a long, heated die that sinters the material simultaneously. It is simpler but does not induce significant fibrillation.

The Performance Difference

The fibrillation achieved in paste extrusion results in products with superior mechanical properties, such as higher tensile strength and flexibility. Ram-extruded parts, like basic rods and thick-walled tubes, typically have lower performance and are not suitable for demanding applications like high-pressure aerospace hoses.

Applications Driven by Performance

The unique properties imparted by the paste extrusion process make it the go-to method for manufacturing critical components across several industries.

High-Integrity Hoses and Liners

The combination of chemical inertness and mechanical strength makes this process ideal for producing aerospace fuel hoses, chemical transfer lines, and industrial pipe liners. These applications demand absolute reliability when handling corrosive or high-purity fluids.

Advanced Wire and Cable Insulation

PTFE is an excellent electrical insulator with a high melting point. Paste extrusion is used to apply a thin, uniform, and durable coating over wires used in aerospace, automotive, and demanding electronic applications where heat and chemical resistance are essential.

Making the Right Choice for Your Goal

Selecting the correct manufacturing process is entirely dependent on the requirements of your final product.

- If your primary focus is maximum mechanical strength for thin-walled products (like hoses or wire insulation): Paste extrusion is the definitive choice because the fibrillation process creates unmatched strength and flexibility.

- If your primary focus is producing simple, solid shapes (like thick rods or basic tubes) where cost is a factor and peak performance is not required: Ram extrusion is a more direct and often more economical alternative.

- If your primary focus is creating a complex, three-dimensional part (like a valve seat or a seal): Neither extrusion method is suitable; you should investigate compression molding of PTFE instead.

Ultimately, understanding that PTFE paste extrusion is a lubricant-assisted, strength-enhancing process is the key to leveraging it for the most demanding material applications.

Summary Table:

| Process Step | Key Action | Outcome |

|---|---|---|

| Paste Creation | Mix fine PTFE powder with lubricant | Forms a dough-like paste for processing |

| Preforming | Compact paste into a cylinder | Creates a uniform billet, removes air |

| Extrusion | Force preform through a die at low temperature | Shapes the product and initiates fibrillation |

| Fibrillation | Particles stretch and interconnect under shear | Creates a fibrous network for superior strength |

| Drying & Sintering | Remove lubricant, then fuse particles at high heat | Produces a solid, non-porous final product |

Need high-performance PTFE components?

The PTFE paste extrusion process detailed above is ideal for creating parts that demand exceptional strength, chemical resistance, and reliability. At KINTEK, we specialize in manufacturing precision PTFE components—including seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors.

We offer custom fabrication from prototypes to high-volume orders, ensuring your specific application requirements are met with precision. Let us put our expertise in advanced polymer processing to work for you.

Contact KINTEK today to discuss your project needs and get a quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- PTFE Chemical Solvent Sampling Spoon

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications