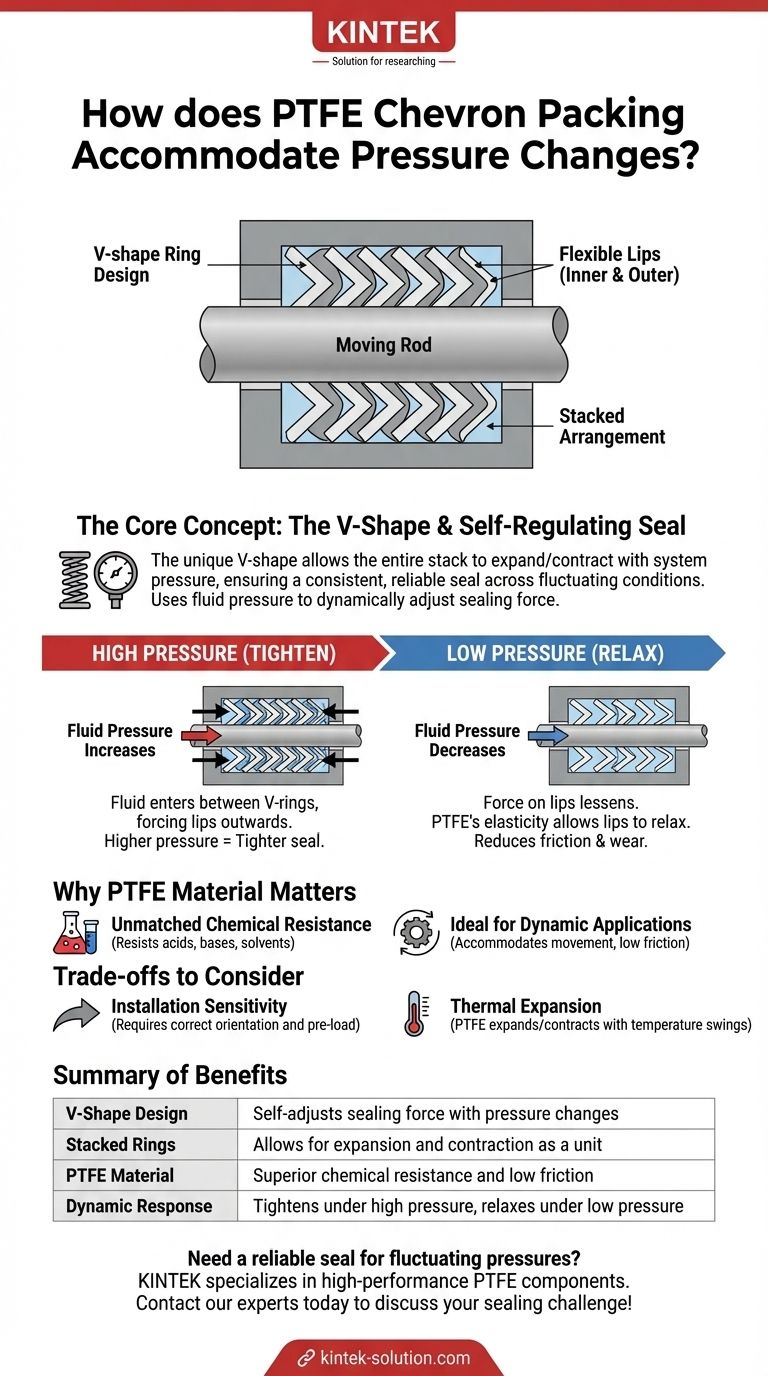

The key is the V-shape. PTFE chevron packing, also known as V-ring packing, consists of a stack of flexible, chevron-shaped rings. This unique configuration allows the entire stack to automatically expand or contract in direct response to system pressure changes, ensuring a consistent and reliable seal across a wide range of operating conditions.

The design of PTFE chevron packing creates a self-regulating seal. Instead of relying on a constant mechanical squeeze, it uses the system's own fluid pressure to dynamically adjust the sealing force, tightening under high pressure and relaxing under low pressure.

The Mechanics of a Self-Adjusting Seal

To understand why this design is so effective in dynamic applications, we need to look at how the components interact under pressure. The system is more than just a simple barrier; it's a responsive mechanism.

The Stacked V-Ring Design

A chevron packing set is not a single, solid component. It is a series of individual rings stacked together. This stacked arrangement is what gives the seal its flexibility to react to force.

Each ring has a distinct "V" shape, which creates flexible "lips" on its inner and outer diameters. When stacked, these rings form a column that can compress and expand as a unit.

How Pressure Activates the Seal

When system pressure increases, fluid enters the spaces between the V-rings. This pressure acts on the internal surfaces of the "V," forcing the lips of each ring outwards.

The inner lip is pressed firmly against the moving rod or shaft, while the outer lip is pressed against the housing wall. The higher the system pressure, the greater the force exerted on the lips, and the tighter the seal becomes.

Responding to Pressure Drops

As system pressure decreases, the force pushing the V-ring lips apart lessens. The natural elasticity of the PTFE material allows the lips to relax slightly.

This self-regulating action reduces friction and minimizes wear on both the packing and the equipment when high-pressure sealing is not required, extending the service life of the components.

The Importance of PTFE as a Material

The V-ring design is only half of the equation. The choice of Polytetrafluoroethylene (PTFE) as the material is what makes this type of packing suitable for the most demanding environments.

Unmatched Chemical Resistance

PTFE is virtually immune to chemical attack. Its strong carbon-fluorine bonds allow it to resist nearly all acids, bases, and organic solvents. This makes it the ideal choice for sealing systems that handle corrosive or aggressive fluids.

Ideal for Dynamic Applications

The combination of the self-adjusting V-shape and PTFE's properties makes this packing exceptionally effective in dynamic applications like hydraulic cylinders and pumps. It can accommodate constant movement while preventing leaks, even when pressure fluctuates rapidly.

Understanding the Trade-offs

While highly effective, PTFE chevron packing requires proper consideration to function correctly. Its performance is directly tied to its installation and operating environment.

Sensitivity to Installation

The performance of a chevron packing stack is highly dependent on correct installation. The rings must be installed in the proper orientation, and the correct initial pre-load (compression) must be applied. Overtightening can cause excessive friction and premature wear.

Thermal Expansion

PTFE has a relatively high coefficient of thermal expansion compared to metals. In applications with wide temperature swings, this must be accounted for in the design of the gland and housing to prevent the seal from becoming too tight or too loose.

Making the Right Choice for Your Goal

Selecting the correct seal depends entirely on the demands of your specific application.

- If your primary focus is handling fluctuating pressure: The self-regulating nature of the V-ring design provides a reliable seal that adapts automatically to hydraulic pressure spikes and drops.

- If your primary focus is chemical compatibility: PTFE's near-universal chemical resistance makes it one of the only viable choices for sealing aggressive or corrosive media.

- If your primary focus is dynamic sealing with high reliability: The combination of an adaptive design and a durable, low-friction material makes chevron packing a premier solution for reciprocating rods and rams.

This design transforms system pressure from a potential problem into the very force that guarantees a robust seal.

Summary Table:

| Feature | Benefit |

|---|---|

| V-Shape Design | Self-adjusts sealing force with pressure changes |

| Stacked Rings | Allows for expansion and contraction as a unit |

| PTFE Material | Provides superior chemical resistance and low friction |

| Dynamic Response | Tightens under high pressure, relaxes under low pressure |

Need a reliable seal for fluctuating pressures? KINTEK specializes in manufacturing high-performance, custom PTFE components like chevron packing for the semiconductor, medical, laboratory, and industrial sectors. Our precision production ensures your seals handle pressure changes flawlessly, from prototypes to high-volume orders. Contact our experts today to discuss your specific sealing challenge!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

People Also Ask

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments