In the chemical and manufacturing industries, PTFE's primary benefit is its profound chemical inertness and high-temperature stability. This unique combination allows it to safely contain, transport, and process highly corrosive materials that would destroy most other substances. It functions as an essential protective barrier, ensuring the integrity of equipment and the purity of the final product in the most demanding operational environments.

The core value of PTFE is not just its resistance to damage, but its ability to remain completely non-reactive. This ensures that it protects both the equipment from the chemical and, just as importantly, the chemical from contamination by the equipment.

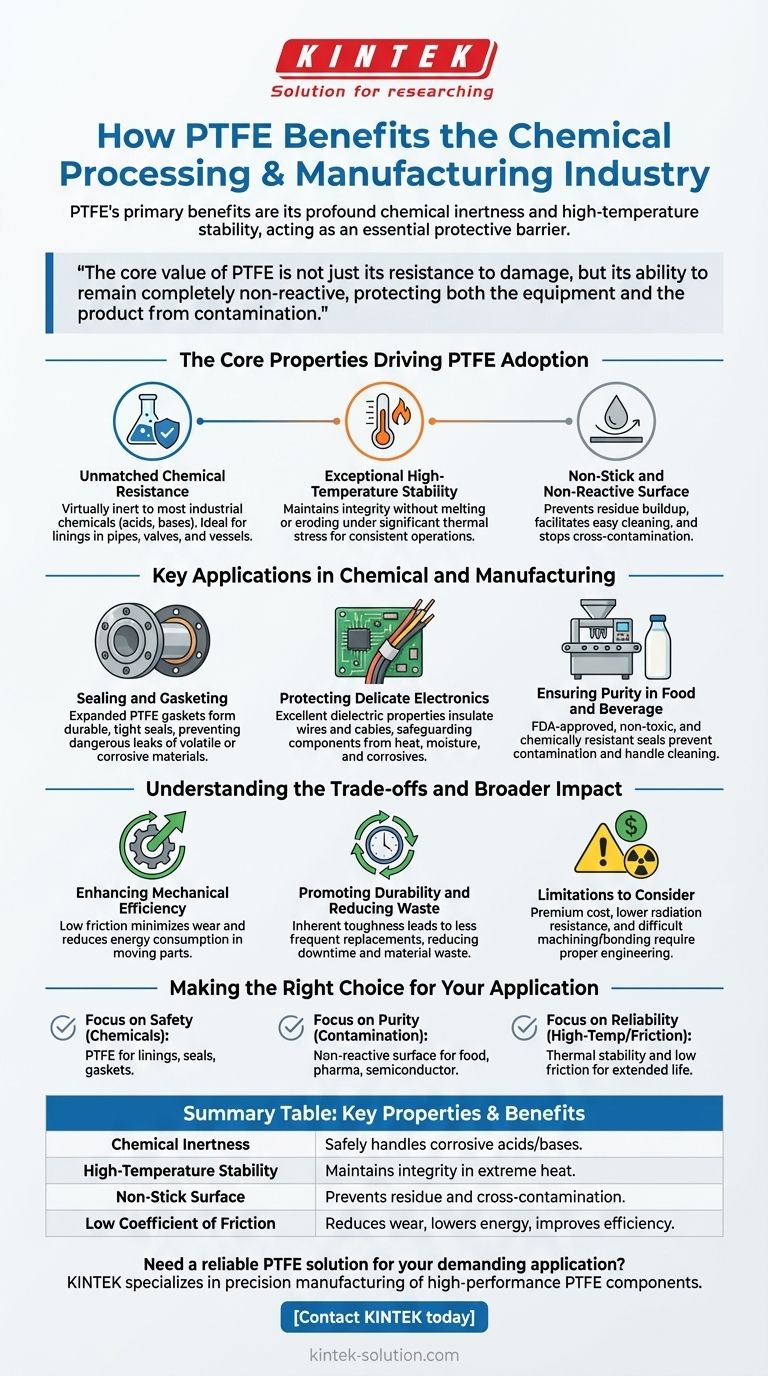

The Core Properties Driving PTFE Adoption

The widespread use of PTFE in demanding industrial settings is a direct result of three fundamental material properties. These characteristics solve persistent challenges related to safety, purity, and equipment longevity.

Unmatched Chemical Resistance

PTFE is virtually inert and does not react with the vast majority of industrial chemicals, including aggressive acids and bases. This makes it the default choice for linings in pipes, valves, and vessels used to handle or transport corrosive substances.

Exceptional High-Temperature Stability

Many chemical processes occur at elevated temperatures. PTFE maintains its structural integrity and protective properties without melting or eroding, even under significant thermal stress, which is critical for consistent and safe operations.

Non-Stick and Non-Reactive Surface

The material's famous non-stick quality is vital for preventing residue buildup. This not only facilitates easier cleaning but also prevents cross-contamination between different batches, a crucial requirement in food, pharmaceutical, and semiconductor manufacturing.

Key Applications in Chemical and Manufacturing

These core properties translate directly into critical applications that are fundamental to modern industrial processes. From preventing catastrophic failures to enabling high-precision production, PTFE is an enabling technology.

Sealing and Gasketing

In plants handling volatile or corrosive materials, preventing leaks is a top safety priority. Expanded PTFE is used to create gaskets for pipe flanges, forming a durable, tight seal that withstands harsh chemicals and extreme temperatures, thereby preventing dangerous leaks.

Protecting Delicate Electronics

The electronics industry relies on PTFE's excellent dielectric (insulating) properties. It is used to insulate wires and cables, protecting them from heat and moisture. Its non-reactive nature also safeguards delicate components from corrosive chemicals used during the manufacturing process.

Ensuring Purity in Food and Beverage

Because PTFE is non-toxic, FDA-approved, and chemically resistant, it is ideal for seals and components that come into contact with food. It can handle acidic or alkaline products without degrading, and its non-stick surface ensures clean processing and prevents contamination.

Understanding the Trade-offs and Broader Impact

While PTFE's primary benefits are clear, understanding its secondary advantages and limitations provides a complete picture for material selection. Its impact extends beyond simple chemical resistance into efficiency and durability.

Enhancing Mechanical Efficiency

PTFE's extremely low coefficient of friction is a significant benefit. In manufacturing machinery, its use in moving parts minimizes friction, which reduces wear and energy consumption. This same principle improves the effectiveness of systems like industrial brakes by ensuring smooth, reliable operation.

Promoting Durability and Reducing Waste

The inherent toughness and longevity of PTFE mean that components made from it need to be replaced far less frequently. This durability reduces operational downtime, maintenance costs, and material waste over the life of the facility.

Limitations to Consider

While incredibly versatile, PTFE is a premium material, and its cost can be a factor. It also has a lower resistance to high-energy radiation and can be difficult to machine or bond compared to traditional metals or plastics. Proper engineering and application are key to leveraging its strengths effectively.

Making the Right Choice for Your Application

Selecting the right material depends entirely on the primary challenge you need to solve. PTFE offers a distinct set of solutions tailored to specific industrial needs.

- If your primary focus is safety and handling aggressive chemicals: PTFE's inertness makes it the superior choice for linings, seals, and gaskets to prevent corrosion and dangerous leaks.

- If your primary focus is product purity and preventing contamination: Its non-reactive, non-stick surface is essential for applications in food, pharmaceutical, or semiconductor manufacturing.

- If your primary focus is reliability in high-temperature or high-friction machinery: PTFE's thermal stability and low-friction properties will reduce wear, lower energy use, and extend the life of your equipment.

Ultimately, PTFE serves as an indispensable problem-solver, enabling processes that would otherwise be impractical or unsafe with conventional materials.

Summary Table:

| Key PTFE Property | Primary Industrial Benefit |

|---|---|

| Chemical Inertness | Safely handles corrosive acids and bases, preventing equipment failure and contamination. |

| High-Temperature Stability | Maintains integrity in extreme heat, ensuring process consistency and safety. |

| Non-Stick Surface | Prevents residue buildup and cross-contamination, crucial for product purity. |

| Low Coefficient of Friction | Reduces wear on machinery, lowers energy consumption, and improves efficiency. |

Need a reliable PTFE solution for your demanding application?

KINTEK specializes in the precision manufacturing of high-performance PTFE components—including custom seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors. Our expertise ensures your equipment is protected from corrosive chemicals, your processes remain contamination-free, and your operations run more efficiently.

Contact KINTEK today to discuss your specific requirements, from prototypes to high-volume production, and leverage the full benefits of PTFE in your operations.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- PTFE Chemical Solvent Sampling Spoon

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What are some common applications of machined PTFE? Leverage its Unique Properties for Demanding Applications

- What are the primary applications of PTFE fasteners and custom parts? Critical Solutions for Extreme Environments

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What are the material advantages of machining Teflon? Unlock Unmatched Chemical & Thermal Resistance