In a direct comparison, expanded PTFE is significantly more flexible and conforms to irregular surfaces far better than standard, solid PTFE gaskets. This superior performance is a direct result of its unique manufacturing process, which transforms solid PTFE into a soft, porous, and highly compressible material. Standard PTFE, by contrast, is a dense and more rigid material.

The core issue isn't simply choosing between "regular" and "expanded" PTFE. It's about matching the gasket's physical structure to the demands of the sealing surface. Expanded PTFE's soft, porous structure is engineered to solve the common problem of sealing imperfect or uneven flanges.

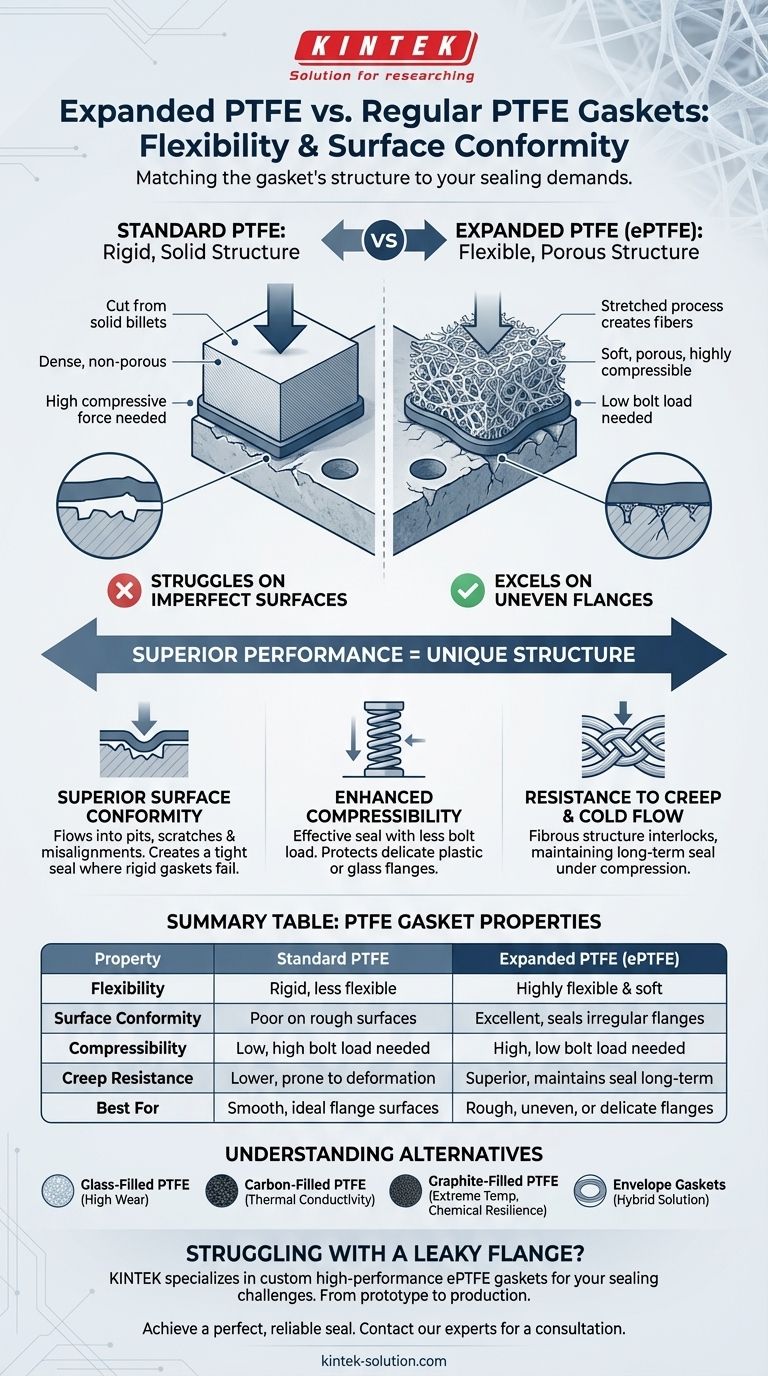

The Fundamental Difference: Structure Dictates Performance

The dramatic contrast in flexibility and conformity between these two gasket types stems from their internal physical structure.

Standard PTFE: Solid and Rigid

Standard PTFE gaskets are cut from solid billets of material. This creates a dense, non-porous structure that is highly valued for its chemical inertness and low-friction surface.

However, this rigidity means it requires more compressive force to create a seal and struggles to fill in the microscopic imperfections found on many industrial flange surfaces.

Expanded PTFE (ePTFE): Soft and Porous

Expanded PTFE is created through a special process that stretches the material, creating a microporous structure of fibers. This process introduces a significant amount of empty space into the material.

This fibrous, porous nature makes the material much softer, more flexible, and easier to compress than its solid counterpart.

Why Expanded PTFE Excels in Difficult Sealing Applications

The unique structure of ePTFE provides distinct mechanical advantages, making it the superior choice for challenging sealing environments.

Superior Surface Conformity

The primary advantage of expanded PTFE is its ability to conform to irregular and rough surfaces. The soft, fibrous material easily flows into pits, scratches, and minor misalignments on a flange face, creating a tight, reliable seal where a rigid gasket would fail.

Enhanced Compressibility

Because of its porous structure, ePTFE is far easier to compress. This means it can achieve an effective seal with less bolt load, which is critical for protecting delicate flanges made from plastic, glass, or other less robust materials.

Resistance to Creep and Cold Flow

Creep, or cold flow, is the tendency of a gasket material to deform or "flow" out from between the flanges over time, leading to a loss of sealing pressure. The fibrous structure of expanded PTFE interlocks under compression, giving it superior resistance to creep and ensuring a more durable, long-term seal.

Understanding the Trade-offs and Alternatives

While expanded PTFE is a powerful problem-solver, a complete understanding of the PTFE gasket family allows for the most precise material selection.

The Limitation of Pure PTFE

The main weakness of pure, unmodified PTFE gaskets is their susceptibility to creep, especially at higher temperatures. Their rigidity also makes them unsuitable for anything other than smooth, perfectly aligned flange surfaces.

When to Use Filled PTFE Gaskets

To overcome the limitations of pure PTFE, functional materials are added to create "filled" variants. These are designed to solve specific challenges that ePTFE may not address.

- Glass-Filled PTFE: Offers enhanced mechanical strength and dimensional stability, making it ideal for applications requiring high wear resistance.

- Carbon-Filled PTFE: Improves thermal conductivity and reduces gas permeability.

- Graphite-Filled PTFE: Provides excellent resistance to extreme temperatures while maintaining low friction and chemical resilience.

The Role of Envelope Gaskets

PTFE envelope gaskets offer a hybrid solution. They combine a soft, compressible insert material with a thin outer "envelope" of PTFE. This design leverages PTFE's chemical resistance while relying on the insert for mechanical strength and sealing capability.

Making the Right Choice for Your Application

Selecting the correct gasket requires matching the material's properties to the specific demands of your system.

- If your primary focus is sealing irregular, rough, or slightly damaged flange surfaces: Expanded PTFE is the definitive choice due to its superior conformity and flexibility.

- If your primary focus is mechanical strength and wear resistance in a chemically aggressive environment: Consider a glass-filled PTFE gasket.

- If your primary focus is sealing against extreme temperatures while maintaining chemical inertness: A graphite-filled PTFE gasket is likely the most suitable option.

- If you have a standard, flat, and ideal sealing surface with moderate demands: A standard, solid PTFE gasket can be a cost-effective and reliable solution.

By understanding the structural differences between PTFE types, you can select the precise gasket material to ensure a reliable, long-lasting seal for your specific challenge.

Summary Table:

| Property | Standard PTFE Gaskets | Expanded PTFE (ePTFE) Gaskets |

|---|---|---|

| Flexibility | Rigid, less flexible | Highly flexible and soft |

| Surface Conformity | Poor on rough surfaces | Excellent, seals irregular flanges |

| Compressibility | Low, requires high bolt load | High, seals with low bolt load |

| Creep/Cold Flow Resistance | Lower, prone to deformation | Superior, maintains seal long-term |

| Best For | Smooth, ideal flange surfaces | Rough, uneven, or delicate flanges |

Struggling with a Leaky or Irregular Flange?

For semiconductor, medical, laboratory, and industrial professionals, the right gasket is critical for process integrity and safety. The superior flexibility and surface conformity of expanded PTFE can solve your toughest sealing challenges.

KINTEK specializes in the precision manufacturing of custom PTFE components, including high-performance expanded PTFE gaskets. We work with you from prototype to high-volume production to deliver a sealing solution perfectly matched to your application's unique demands.

Let us help you achieve a perfect, reliable seal. Contact our experts today for a consultation!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

People Also Ask

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments