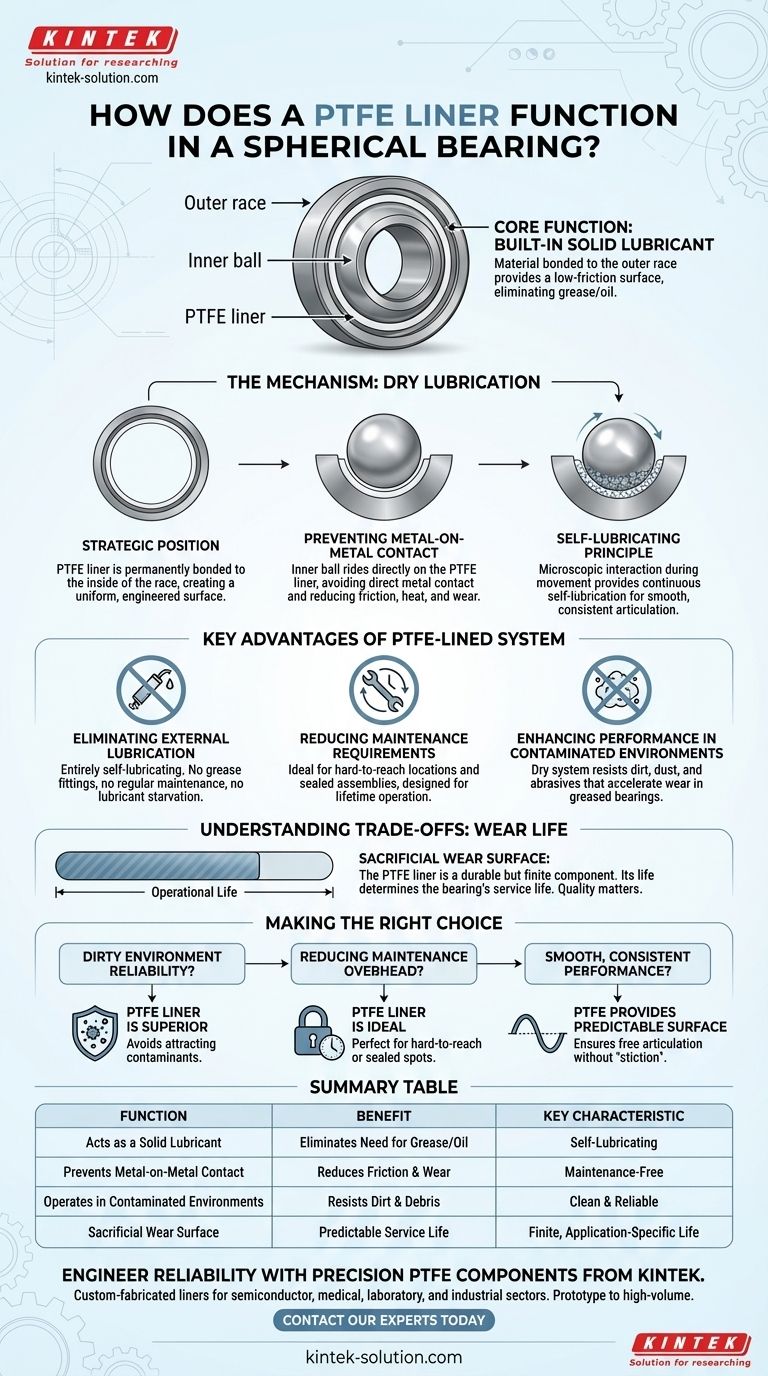

At its core, a PTFE liner in a spherical bearing or rod end functions as a built-in, solid lubricant. It is a material bonded to the inner surface of the bearing's outer race that provides a low-friction surface for the ball to move against, completely eliminating the need for traditional grease or oil.

The fundamental purpose of a PTFE liner is to transform a standard bearing into a maintenance-free, self-lubricating component. It solves the critical problem of friction and wear in applications where external lubrication is impractical, difficult, or would attract harmful contaminants.

The Core Mechanism: How Dry Lubrication Works

A PTFE-lined bearing operates on a simple yet highly effective principle. The design strategically places a durable, low-friction material precisely where it is needed most.

The Liner's Strategic Position

The PTFE (Polytetrafluoroethylene) liner is permanently adhered to the inside of the bearing's outer housing, often called the race or body. This creates a uniform, engineered surface.

Preventing Metal-on-Metal Contact

The bearing's inner ball rides directly on this PTFE liner. This arrangement ensures there is no direct metal-on-metal contact during operation, which is the primary source of high friction, heat generation, and component wear.

The Self-Lubricating Principle

As the ball articulates and moves, it rubs against the PTFE liner. This microscopic interaction provides its own lubrication, ensuring smooth and consistent movement without requiring any external grease or oil.

Key Advantages of a PTFE-Lined System

Choosing a bearing with a PTFE liner is a deliberate design decision that offers significant operational benefits, particularly in demanding environments.

Eliminating External Lubrication

The most immediate benefit is that the bearing becomes entirely self-lubricating. This removes the need for grease fittings, regular maintenance schedules, and the risk of lubricant starvation.

Reducing Maintenance Requirements

Because no re-lubrication is necessary, these bearings are ideal for installation in hard-to-reach locations or in sealed assemblies designed to last the lifetime of a product without intervention.

Enhancing Performance in Contaminated Environments

Traditional wet lubricants like grease can be a magnet for dirt, dust, and other abrasive particles. This mixture can create a grinding paste that dramatically accelerates wear. A PTFE liner, being a dry system, avoids this problem entirely.

Understanding the Trade-offs

While highly effective, PTFE liners are an engineered solution with specific characteristics. Understanding their operational limits is key to proper application.

The Concept of Wear Life

The PTFE liner is a sacrificial component. While extremely durable, it has a finite operational life and will eventually wear down. The life of the bearing is determined by the life of the liner, which is why selecting a high-quality component is critical.

Application-Specific Performance

A PTFE liner is the standard for most high-performance, maintenance-free applications. However, the choice between a lined bearing and a traditional metal-on-metal bearing depends entirely on the application's demands for load, speed, and environmental conditions. The liner excels where cleanliness and zero maintenance are the priority.

Making the Right Choice for Your Application

Selecting the correct bearing type depends on your primary engineering goal.

- If your primary focus is reliability in a dirty environment: A PTFE liner is superior as it avoids attracting abrasive contaminants that can destroy a greased bearing.

- If your primary focus is reducing maintenance overhead: The self-lubricating nature of a PTFE liner is the ideal choice for hard-to-reach locations or sealed-for-life assemblies.

- If your primary focus is smooth, consistent performance: The liner provides a predictable, low-friction surface that ensures free articulation without the "stiction" sometimes found in greased joints.

Ultimately, choosing a PTFE-lined bearing is a strategic decision to prioritize clean, maintenance-free reliability in your mechanical system.

Summary Table:

| Function | Benefit | Key Characteristic |

|---|---|---|

| Acts as a Solid Lubricant | Eliminates Need for Grease/Oil | Self-Lubricating |

| Prevents Metal-on-Metal Contact | Reduces Friction & Wear | Maintenance-Free |

| Operates in Contaminated Environments | Resists Dirt & Debris | Clean & Reliable |

| Sacrificial Wear Surface | Predictable Service Life | Finite, Application-Specific Life |

Engineer reliability into your system with precision PTFE components from KINTEK.

Are you designing for demanding environments in the semiconductor, medical, laboratory, or industrial sectors? Our custom-fabricated PTFE liners, seals, and labware provide the maintenance-free, self-lubricating performance you need. We specialize in precision production from prototypes to high-volume orders.

Contact our experts today to discuss how our PTFE solutions can solve your critical friction and contamination challenges.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Customizable PTFE Rods for Advanced Industrial Applications

People Also Ask

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments