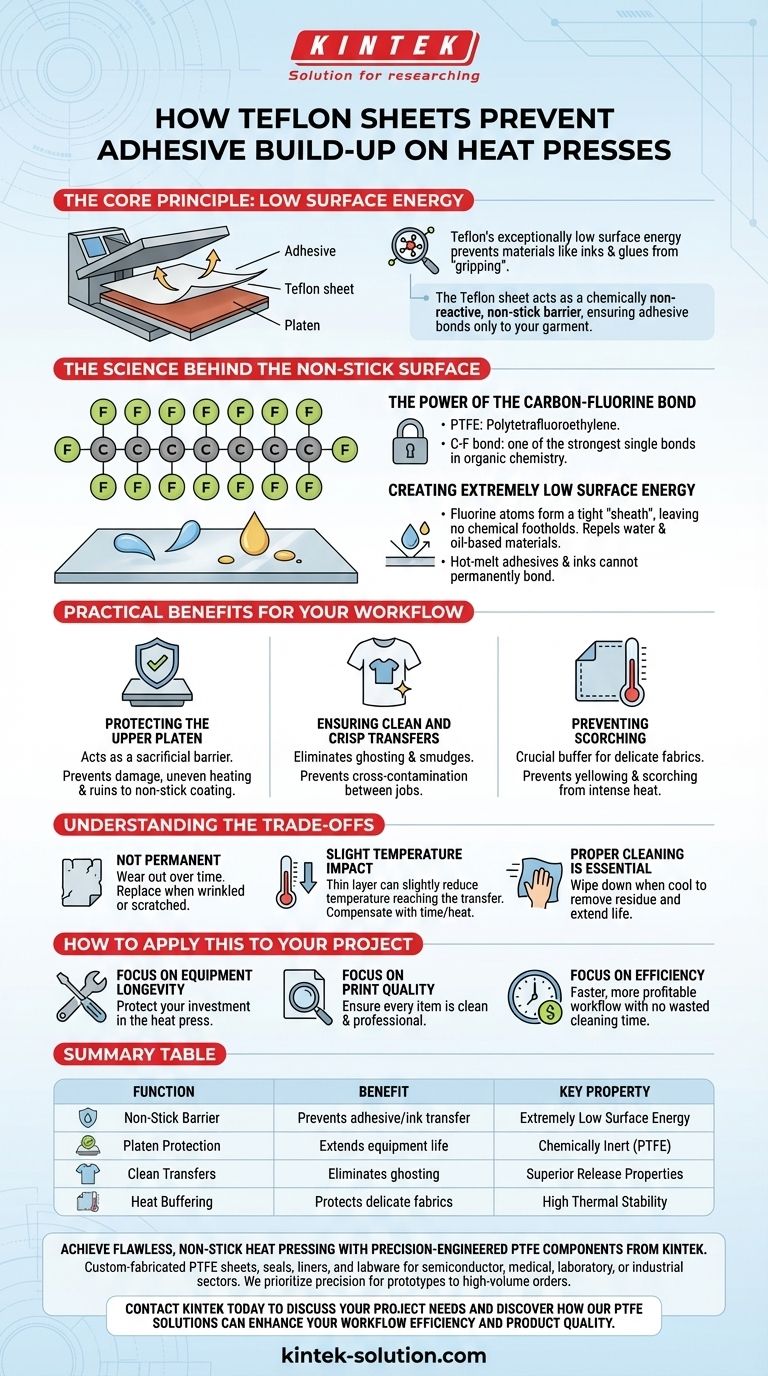

At its core, a Teflon sheet prevents adhesive build-up on a heat press because of its exceptionally low surface energy. This unique chemical property means that other materials, like inks and glues, have virtually nothing to "grip" onto, forcing them to release from the sheet instead of sticking to it or your equipment.

The fundamental problem is that heat activates adhesives and inks, making them eager to bond with any surface they touch. A Teflon sheet acts as a chemically non-reactive, non-stick barrier, ensuring that the only thing the adhesive bonds to is your intended garment.

The Science Behind the Non-Stick Surface

To understand why this works, we need to look at the material itself. Teflon is the brand name for a polymer called Polytetrafluoroethylene, or PTFE. Its effectiveness comes down to its unique molecular structure.

The Power of the Carbon-Fluorine Bond

At the atomic level, PTFE consists of a long chain of carbon atoms completely surrounded by fluorine atoms. The bond between carbon and fluorine is one of the strongest single bonds in organic chemistry.

This creates an incredibly stable and non-reactive molecule. The fluorine atoms form a tight, dense "sheath" around the carbon backbone, leaving no chemical footholds for other substances to attach to.

Creating Extremely Low Surface Energy

This powerful chemical structure results in what is known as low surface energy. Think of it like a perfectly polished floor where nothing can find friction.

Because the Teflon surface is so non-reactive and stable, it repels almost everything, including both water-based (hydrophobic) and oil-based (oleophobic) materials. Hot-melt adhesives and inks simply can't establish a permanent bond with it.

Practical Benefits for Your Workflow

Understanding the science reveals why a Teflon sheet is more than just a convenience; it's a critical tool for quality and efficiency.

Protecting the Upper Platen

The upper platen of your heat press is a precisely engineered surface. Adhesive and ink build-up can bake onto it, causing permanent damage, creating uneven heating spots, and ruining its non-stick coating over time. The Teflon sheet acts as a sacrificial, protective barrier.

Ensuring Clean and Crisp Transfers

Without a sheet, a small fleck of adhesive or ink from one job can easily transfer from the platen onto the next garment. This causes ghosting, smudges, and costly mistakes. The sheet ensures a clean surface for every single press.

Preventing Scorching

The sheet also acts as a crucial buffer between the hot metal platen and your garment. For delicate fabrics, this can prevent the dreaded yellowing or scorching that occurs from direct, intense heat exposure.

Understanding the Trade-offs

While indispensable, it's important to view Teflon sheets as a consumable tool with specific characteristics.

They Are Not Permanent

Teflon sheets wear out. Over time, they can develop wrinkles, scratches, or a build-up of residue that even their non-stick surface can't repel. A worn-out sheet loses its effectiveness and should be replaced immediately.

A Slight Impact on Temperature

Adding a layer—even a thin one—between the heat source and the garment can slightly reduce the temperature that reaches your transfer. Experienced operators often add a few degrees or a few extra seconds to their press time to compensate for this.

Proper Cleaning is Essential

To maximize the life of your sheet, it's crucial to wipe it down with a soft, damp cloth after it has cooled. This removes any temporary residue before it has a chance to carbonize and bond during the next press cycle.

How to Apply This to Your Project

Your specific goal will determine how you view the role of the Teflon sheet in your process.

- If your primary focus is equipment longevity: Using a Teflon sheet is the single best way to protect the investment you've made in your heat press.

- If your primary focus is print quality: The sheet is non-negotiable for preventing cross-contamination and ensuring every item is clean and professional.

- If your primary focus is efficiency: A clean platen means no time wasted cleaning stubborn residue or re-printing mistakes, leading to a faster and more profitable workflow.

By acting as a perfect release agent, the Teflon sheet is the simple tool that ensures your intended design is the only thing that transfers.

Summary Table:

| Function | Benefit | Key Property |

|---|---|---|

| Non-Stick Barrier | Prevents adhesive/ink transfer to platen | Extremely Low Surface Energy |

| Platen Protection | Extends equipment life, prevents damage | Chemically Inert (PTFE) |

| Clean Transfers | Eliminates ghosting and contamination | Superior Release Properties |

| Heat Buffering | Protects delicate fabrics from scorching | High Thermal Stability |

Achieve flawless, non-stick heat pressing with precision-engineered PTFE components from KINTEK.

Whether you are in the semiconductor, medical, laboratory, or industrial sector, our custom-fabricated PTFE sheets, seals, liners, and labware are designed to provide superior chemical resistance and non-stick performance, protecting your valuable equipment and ensuring consistent, high-quality results.

We specialize in custom fabrication from prototypes to high-volume orders, prioritizing precision to meet your exact specifications.

Contact KINTEK today to discuss your project needs and discover how our PTFE solutions can enhance your workflow efficiency and product quality.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What are the key benefits of PTFE in custom fabrication? Unlock Performance in Extreme Conditions

- Why is PTFE suitable for cryogenic or high-temperature applications? Unmatched Thermal Stability from -450°F to 500°F

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications

- What are the base characteristics of PTFE? Unlocking Extreme Performance in Friction, Temperature, and Chemical Resistance