Teflon sheets are a critical tool in screen printing because they provide a non-stick, protective barrier. This surface prevents pallet adhesives, inks, and other residues from permanently sticking to your equipment, particularly your squeegees and heat press platens, ensuring a cleaner and more efficient printing process.

The core function of a Teflon sheet is to introduce a non-stick, low-friction surface into the printing process. This simple addition prevents the messy buildup that causes inconsistent prints, damages tools, and creates significant cleanup challenges.

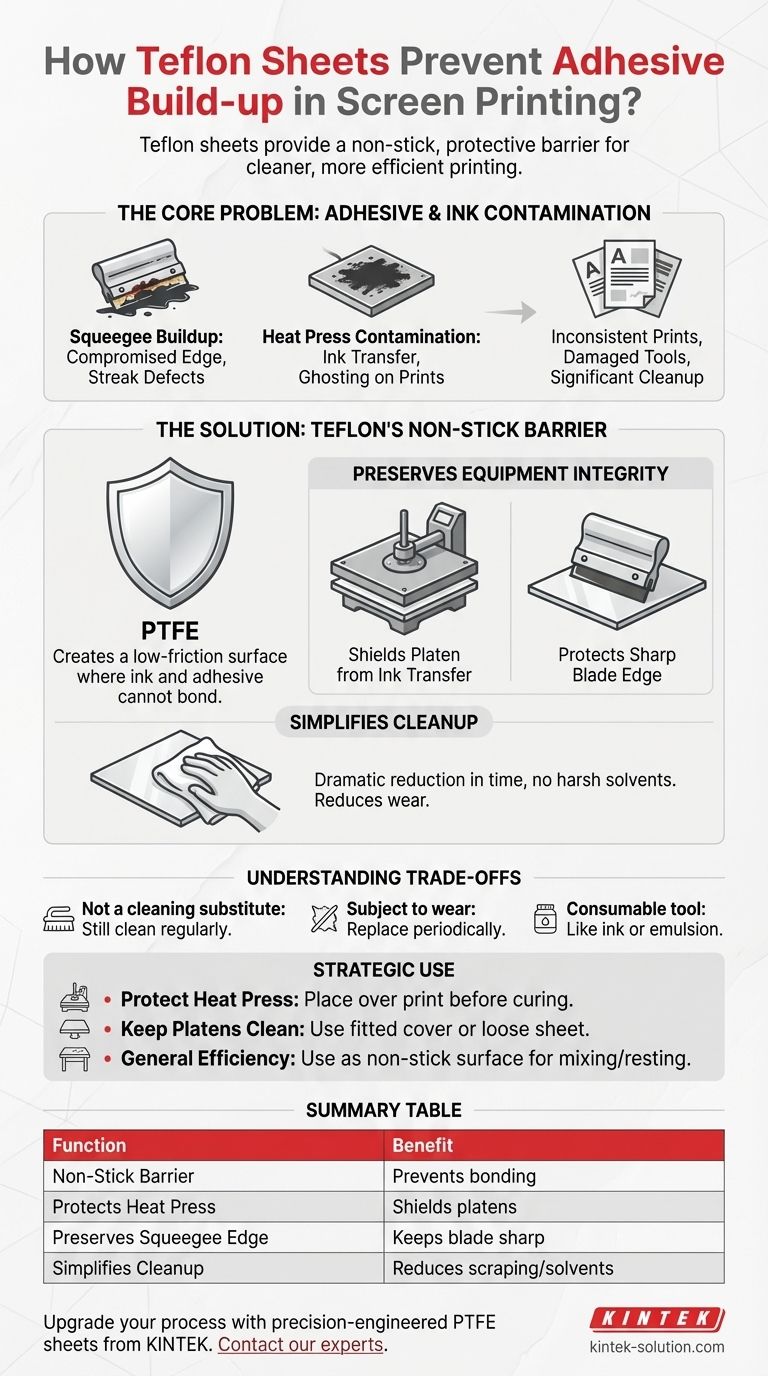

The Core Problem: Adhesive and Ink Contamination

Why Buildup Occurs

In a typical screen printing workflow, a spray adhesive is used on the platen (the board the garment rests on) to keep the material from shifting. During the printing process, ink is forced through a screen with a squeegee.

Inevitably, small amounts of this adhesive and excess ink can transfer from the garment or screen onto your tools.

The Impact on Your Equipment

When adhesive and dried ink accumulate on a squeegee, it compromises the blade's smooth, sharp edge. This can create nicks and uneven spots.

For a heat press, stray ink can transfer and bake onto the upper platen, which can then ghost onto the next garment you cure.

The Impact on Your Prints

A contaminated squeegee cannot apply an even, consistent layer of ink. This leads directly to print defects like streaks, light spots, and blurry edges.

A dirty heat press can ruin an otherwise perfect print by stamping it with old, cured ink from a previous job.

How Teflon Provides the Solution

Creating a Non-Stick Barrier

The chemical name for Teflon is Polytetrafluoroethylene (PTFE). Its defining characteristic is an extremely low coefficient of friction, making it one of the most non-stick materials known.

When placed between a heat source and a print, or used to cover a work surface, it acts as a perfect shield. Ink and adhesives simply have nothing to bond to.

Preserving Equipment Integrity

Using a Teflon sheet over a print during heat curing prevents any ink from ever touching your heat press platen.

While not used between the squeegee and screen during a print, keeping a Teflon sheet on a nearby surface to rest the squeegee on prevents it from picking up stray contaminants. This protects the critical sharp edge of the blade.

Simplifying Cleanup

The most immediate benefit is a dramatic reduction in cleanup time. Instead of scraping cured ink off a platen or using harsh solvents on your tools, you can simply wipe the Teflon sheet clean.

This not only saves time but also reduces the wear and tear on your expensive equipment.

Understanding the Trade-offs

Not a Substitute for Proper Cleaning

Teflon sheets are a preventative measure, not a replacement for good shop hygiene. You still need to clean your screens, squeegees, and platens regularly to ensure high-quality output.

Subject to Wear and Tear

These sheets are durable but not indestructible. Over time, they can become creased, scratched, or worn. Any imperfection on the sheet's surface can potentially transfer to your final print, especially during heat pressing.

They Are Consumables

Think of Teflon sheets as a consumable tool, much like ink or screen emulsion. They will need to be replaced periodically to maintain their effectiveness and ensure flawless results.

Making the Right Choice for Your Goal

By strategically placing Teflon sheets in your workflow, you can solve specific, common problems.

- If your primary focus is protecting your heat press: Always place a Teflon sheet directly over the printed design before curing to prevent ink transfer.

- If your primary focus is keeping platens clean: Use a fitted Teflon platen cover or a loose sheet to shield the surface from spray adhesive overspray.

- If your primary focus is general efficiency: Designate a Teflon sheet as a non-stick work surface for mixing inks or resting messy squeegees and spatulas to minimize cleanup.

Ultimately, integrating Teflon sheets into your process is a simple, low-cost investment in print consistency, quality, and speed.

Summary Table:

| Function | Benefit |

|---|---|

| Non-Stick Barrier | Prevents ink/adhesive from bonding to equipment |

| Protects Heat Press | Shields platens from ink transfer during curing |

| Preserves Squeegee Edge | Keeps blade sharp by providing a clean resting surface |

| Simplifies Cleanup | Reduces scraping and solvent use; just wipe clean |

Upgrade your screen printing process with precision-engineered PTFE sheets from KINTEK.

Our high-quality Teflon components are manufactured to the exacting standards required by specialized industries. Whether you need standard sizes or custom-fabricated platen covers and work surfaces, KINTEK delivers durable, non-stick solutions that protect your equipment and ensure flawless prints.

Contact our experts today to discuss your needs, from prototypes to high-volume orders, and see how our PTFE solutions can boost your shop's efficiency and print quality.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What are some applications of CNC machined PTFE parts? Critical Components for Medical, Electrical & Food Industries

- Why is dimensional stability a concern when machining PTFE? Ensure Accurate, Stable PTFE Components

- What is the hardness range of PTFE on the Shore D scale? Leveraging Its Softness for Superior Performance

- How does PTFE compare to other low-friction plastics like UHMW-PE and Nylon? A Guide to Material Selection

- What are some important physical property values for PTFE? Master Its Extreme Performance for Demanding Applications