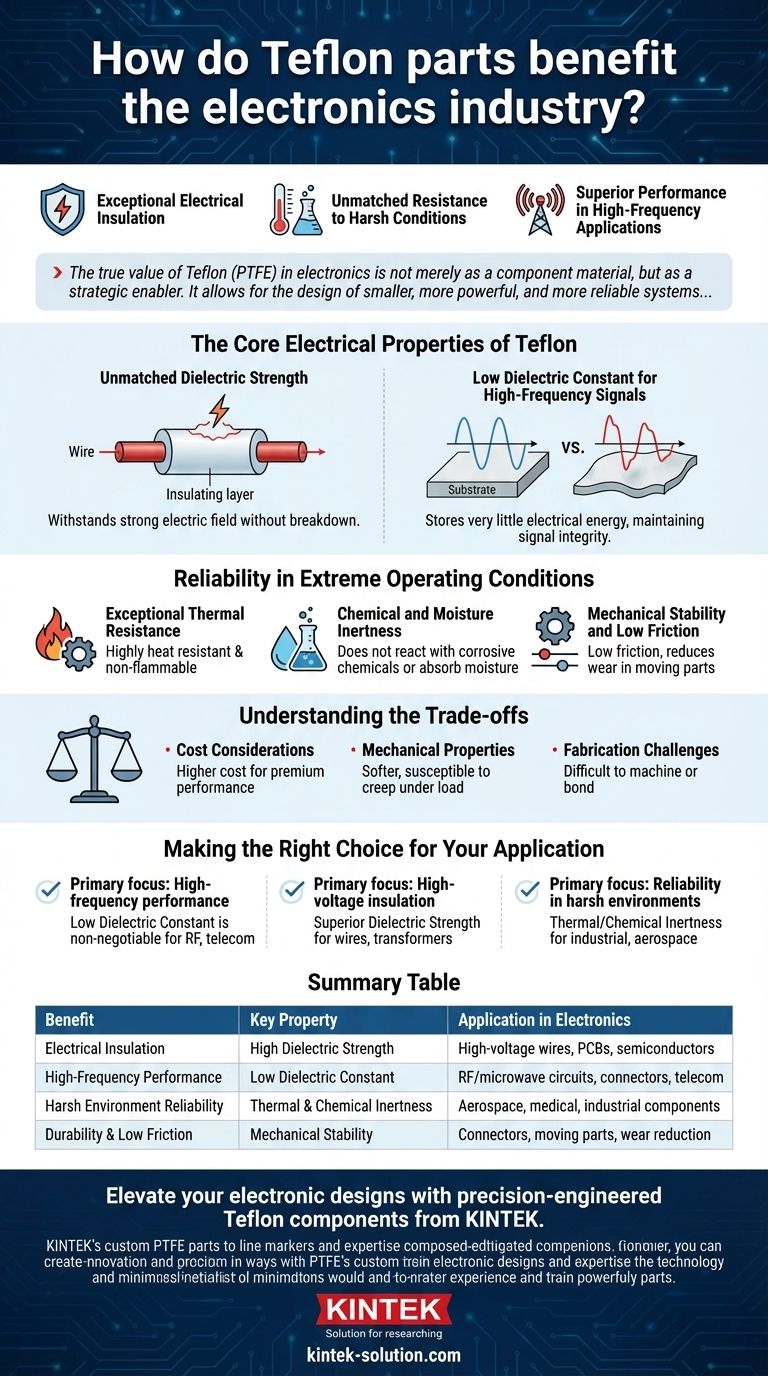

At its core, Teflon provides three critical benefits to the electronics industry: exceptional electrical insulation, unmatched resistance to harsh conditions, and superior performance in high-frequency applications. Its unique combination of properties allows electronic components to function reliably where other materials would fail, safeguarding them from high voltages, corrosive chemicals, and extreme temperatures.

The true value of Teflon (PTFE) in electronics is not merely as a component material, but as a strategic enabler. It allows for the design of smaller, more powerful, and more reliable systems that can operate in demanding environments, from aerospace to medical devices.

The Core Electrical Properties of Teflon

Teflon’s primary role in electronics stems from its fundamental molecular structure, which makes it an almost perfect electrical insulator.

Unmatched Dielectric Strength

Dielectric strength refers to a material's ability to withstand a strong electric field without breaking down and conducting electricity.

Teflon possesses an extremely high dielectric strength, making it the ideal choice for insulating high-voltage wires, cables, and internal components in semiconductors and printed circuit boards (PCBs).

This property is critical for preventing electrical arcing or short circuits, which can cause catastrophic component failure and safety hazards.

Low Dielectric Constant for High-Frequency Signals

In high-frequency applications, such as RF and microwave circuits, the goal is to transmit a signal with minimal loss or distortion.

Teflon has a very low dielectric constant, which means it stores very little electrical energy from a passing field. This ensures that the signal’s integrity is maintained, preventing interference and power loss.

This makes it an essential material for high-performance connectors and as a substrate for advanced circuit boards used in telecommunications and radar systems.

Reliability in Extreme Operating Conditions

Beyond its electrical characteristics, Teflon provides a level of durability and resilience that is essential for mission-critical electronics.

Exceptional Thermal Resistance

Electronic components generate heat, and many operate in high-temperature environments. Teflon is highly resistant to heat and is non-flammable.

This thermal stability prevents the material from melting, degrading, or catching fire, which protects sensitive components and enhances the overall safety of the device.

Chemical and Moisture Inertness

Teflon is famously chemically inert, meaning it does not react with corrosive chemicals like strong acids or solvents. It is also highly resistant to moisture absorption.

This protects delicate electronic parts from corrosion and damage, both during manufacturing processes involving chemicals and in the final operating environment where exposure may occur.

Mechanical Stability and Low Friction

Teflon’s low coefficient of friction makes it an excellent material for parts that experience movement or contact, reducing wear and tear over the component’s lifespan.

This is beneficial in applications like connectors that are frequently mated and unmated, or in legacy components like mouse tracking balls and touchpads.

Understanding the Trade-offs

While Teflon offers significant advantages, it is essential to understand its limitations to make an informed design decision.

Cost Considerations

PTFE is a premium performance polymer, and its cost is higher than that of commodity plastics like polyethylene or PVC. Its value is justified by its long service life and the enhanced performance it provides under harsh conditions.

Mechanical Properties

While durable, Teflon is a relatively soft material and can be susceptible to "creep" or deformation when placed under a constant mechanical load over time. This must be accounted for in structural designs.

Fabrication Challenges

Teflon can be more challenging to machine or bond compared to other plastics. Its inert surface makes it difficult for adhesives to form a strong bond, often requiring special surface treatments.

Making the Right Choice for Your Application

Selecting Teflon is a decision driven by the specific performance demands of your electronic system.

- If your primary focus is high-frequency performance: Teflon's low dielectric constant is non-negotiable for ensuring signal integrity in RF circuit boards, coaxial cables, and connectors.

- If your primary focus is high-voltage insulation: Its superior dielectric strength provides the safety and reliability needed for insulating wires, transformers, and semiconductor components.

- If your primary focus is reliability in harsh environments: Teflon's thermal stability and chemical inertness are critical for protecting electronics in industrial, aerospace, or chemical processing applications.

Ultimately, choosing Teflon is an investment in performance and long-term reliability for your most demanding electronic designs.

Summary Table:

| Benefit | Key Property | Application in Electronics |

|---|---|---|

| Electrical Insulation | High Dielectric Strength | High-voltage wires, PCBs, semiconductors |

| High-Frequency Performance | Low Dielectric Constant | RF/microwave circuits, connectors, telecom |

| Harsh Environment Reliability | Thermal & Chemical Inertness | Aerospace, medical, industrial components |

| Durability & Low Friction | Mechanical Stability | Connectors, moving parts, wear reduction |

Elevate your electronic designs with precision-engineered Teflon components from KINTEK.

For engineers and manufacturers in the semiconductor, medical, and industrial sectors, KINTEK's custom PTFE parts (seals, liners, labware, and more) are the key to unlocking superior reliability and performance. We specialize in transforming the unique properties of Teflon into solutions that protect your most sensitive components from high voltages, extreme temperatures, and corrosive chemicals.

Whether you need prototypes or high-volume production, our commitment to precision manufacturing ensures your components meet the highest standards. Invest in performance and long-term reliability—contact our experts today to discuss your project requirements.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech