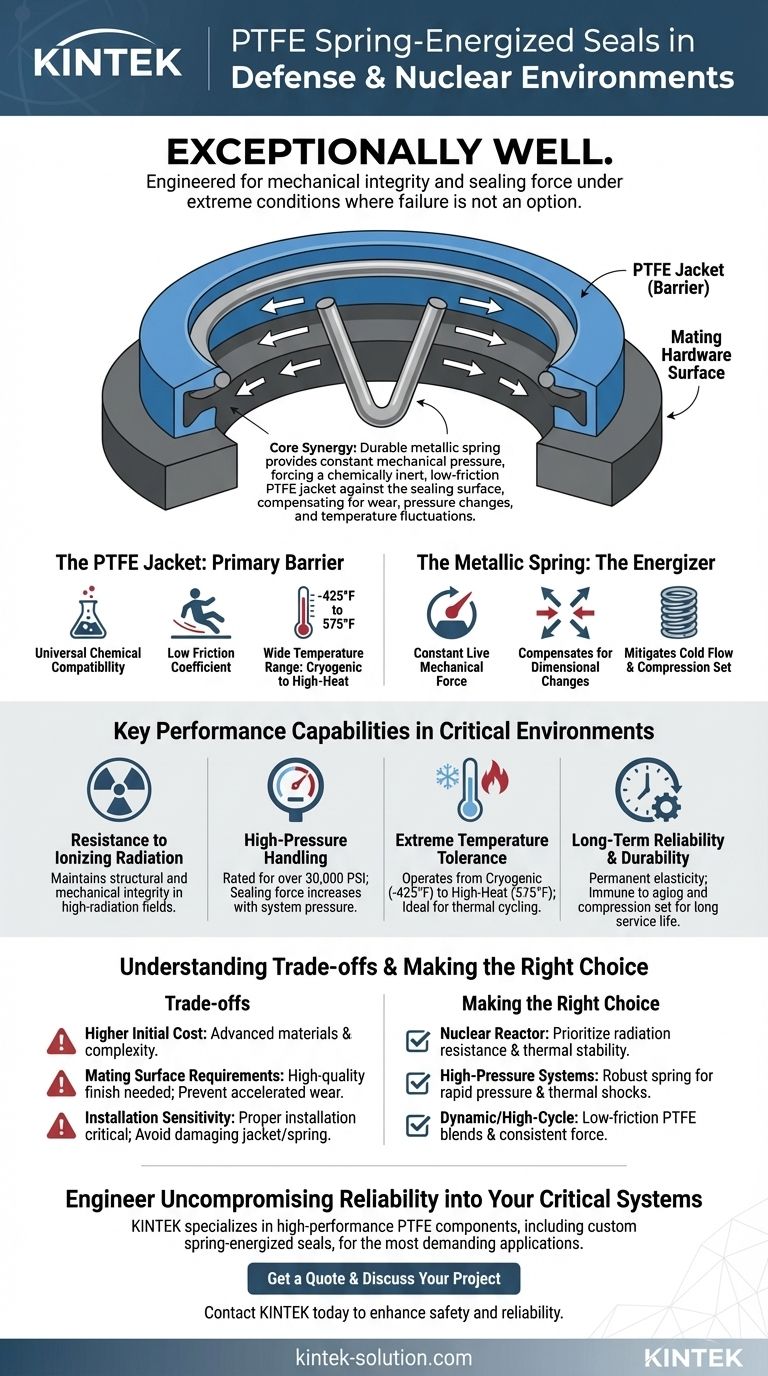

In short, they perform exceptionally well. PTFE spring-energized seals are specifically engineered to maintain their mechanical integrity and sealing force under the extreme conditions characteristic of defense and nuclear environments, including ionizing radiation, high-pressure cycling, and wide temperature swings. Their unique design makes them a default choice for critical systems where failure is not an option.

The core reason for their success lies in a simple yet powerful design synergy: a durable metallic spring provides constant mechanical pressure, forcing a chemically inert and low-friction PTFE jacket against the sealing surface. This combination overcomes the natural limitations of PTFE, creating a highly reliable seal that actively compensates for wear, pressure changes, and temperature fluctuations.

The Core Design: Why Spring-Energization is Critical

To understand the performance of these seals, you must first understand how their two key components work together to create a system far more capable than the sum of its parts.

The Role of the PTFE Jacket

The outer seal material, Polytetrafluoroethylene (PTFE), is the primary barrier. It is selected for its remarkable inherent properties.

It offers universal chemical compatibility, making it inert to aggressive fluids and gases. It also has an extremely low friction coefficient and can operate across a vast temperature range, from cryogenic (-425°F) to high-heat (575°F) conditions.

The Function of the Metallic Spring

The internal spring is the "energizer" and the key to the seal's reliability. It provides a constant, live mechanical force on the PTFE jacket lips.

This ensures a consistent, tight seal against the mating hardware, even when the system is not pressurized. It actively compensates for any dimensional changes caused by thermal expansion or contraction.

Overcoming Material Limitations

Standard PTFE seals can be prone to cold flow (a type of material creep) and compression set, where the material loses its "memory" and ability to spring back into shape.

The internal spring completely mitigates this weakness. It acts as the seal's permanent memory, ensuring the PTFE jacket maintains constant contact and sealing force, regardless of material relaxation, wear, or age-related embrittlement.

Key Performance Capabilities in Critical Environments

The combination of the spring and PTFE jacket delivers specific capabilities essential for defense and nuclear applications.

Resistance to Ionizing Radiation

In nuclear environments, from reactor controls to radiation-shielded enclosures, materials must resist degradation from radiation. PTFE spring-energized seals maintain their structural and mechanical integrity over long service periods in these high-radiation fields.

Performance Under High Pressure

These seals are engineered to handle extreme pressure differentials, with some designs rated for over 30,000 PSI. The spring ensures a baseline seal at low pressure, while system pressure itself acts on the seal to increase the sealing force, creating a highly effective and responsive system.

Extreme Temperature Tolerance

The operational range of these seals is exceptionally wide. They maintain flexibility and sealing force in cryogenic applications down to -425°F and in high-temperature service up to 575°F, making them ideal for systems that experience rapid and severe thermal cycling.

Long-Term Reliability and Durability

Unlike traditional elastomeric seals that can harden and fail with age, the spring-energized design offers permanent elasticity. This immunity to aging and compression set allows for high cycle rates and repeated installations, ensuring predictable performance over the life of the equipment.

Understanding the Trade-offs

While highly effective, specifying these seals requires acknowledging their specific engineering context. They are not a universal drop-in replacement for simpler seals without careful consideration.

Higher Initial Cost

These are advanced, multi-component seals designed for high-performance applications. Their manufacturing complexity and material costs are inherently higher than those of standard O-rings or simple elastomeric seals.

Mating Surface Requirements

To achieve optimal performance and prevent leakage, the hardware mating surfaces must have a high-quality finish. The constant force from the spring can cause accelerated wear on softer mating surfaces if the material compatibility and surface hardness are not correctly specified.

Installation Sensitivity

While durable, proper installation is critical. Care must be taken to avoid scratching the PTFE jacket or damaging the spring during assembly, as this can compromise the integrity of the sealing interface.

Making the Right Choice for Your Application

Selecting the correct seal configuration depends entirely on the specific demands of your system.

- If your primary focus is reliability in a nuclear reactor: Prioritize seals with materials specifically tested and rated for long-term radiation exposure and thermal stability.

- If your primary focus is performance in a high-pressure missile system: Specify a design with a robust spring energizer and jacket profile capable of withstanding rapid pressure cycling and extreme temperature shocks.

- If your primary focus is a dynamic, high-cycle application: Focus on low-friction PTFE blends and a spring design that provides a consistent sealing force to minimize wear on both the seal and the hardware.

Ultimately, leveraging a spring-energized PTFE seal is a decision to engineer reliability directly into a critical system from the start.

Summary Table:

| Capability | Performance Benefit |

|---|---|

| Radiation Resistance | Maintains structural integrity in high-radiation fields (e.g., reactor controls). |

| High-Pressure Handling | Rated for extreme pressures (over 30,000 PSI); sealing force increases with system pressure. |

| Extreme Temperature Tolerance | Operates from cryogenic (-425°F) to high-heat (575°F) conditions. |

| Long-Term Reliability | Spring provides permanent elasticity, immune to aging and compression set for long service life. |

Engineer Uncompromising Reliability into Your Critical Systems

When failure is not an option, the precision and performance of your components are paramount. KINTEK specializes in manufacturing high-performance PTFE components, including custom spring-energized seals, for the most demanding applications in the semiconductor, medical, laboratory, industrial, and defense sectors.

We prioritize precision production and offer custom fabrication from prototypes to high-volume orders, ensuring your seals meet the exact specifications required for extreme environments.

Contact KINTEK today to discuss your project requirements and discover how our expertise can enhance the safety and reliability of your critical systems.

Get a Quote & Discuss Your Project

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials