At its core, a PTFE slide bearing ensures consistent performance because of the fundamental material science of Polytetrafluoroethylene (PTFE) itself. Its remarkably low and stable coefficient of friction, combined with its self-lubricating properties and chemical inertness, creates a predictable and reliable surface that functions consistently across a wide range of temperatures, pressures, and speeds without degradation or external maintenance.

The consistency of a PTFE bearing is not derived from a complex mechanical design but from the simple, unchanging molecular properties of its core material. This makes its performance inherently predictable and exceptionally reliable over time.

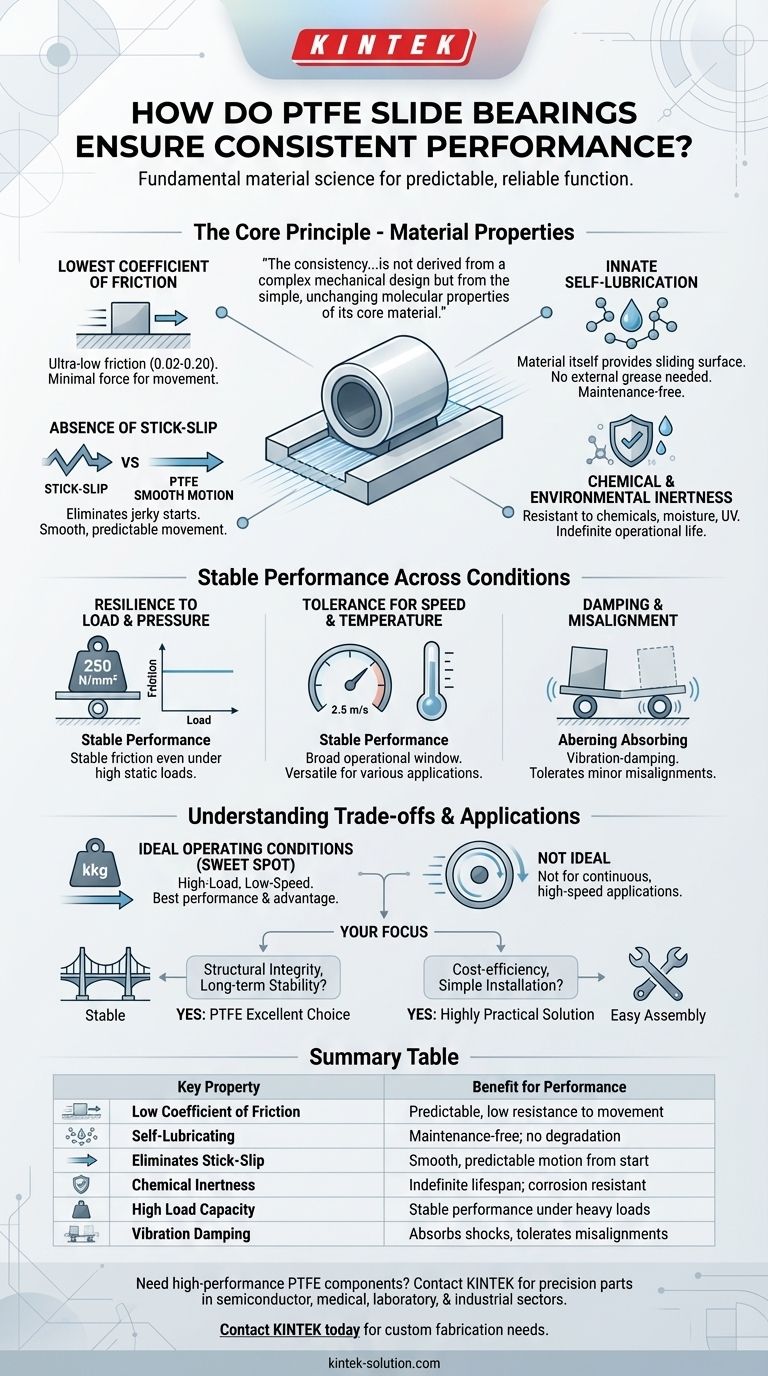

The Foundation of Consistency: Core Material Properties

The reliability of a PTFE bearing is rooted in three key characteristics of the material. Understanding these properties explains why its performance is so dependable.

The Lowest Coefficient of Friction

PTFE boasts one of the lowest coefficients of friction of any solid material, typically ranging from 0.02 to 0.20.

This extremely low friction means that the force required to initiate and sustain movement remains minimal and, more importantly, constant.

Innate Self-Lubrication

These bearings are inherently self-lubricating. The material itself provides the low-friction sliding surface, eliminating the need for external greases or oils.

This quality is the reason they are considered maintenance-free, as there are no lubricants to reapply or systems to check. It also prevents the performance degradation that can occur when lubricants fail or become contaminated.

Absence of Stick-Slip

A common problem in mechanical systems is "stick-slip," where the static friction (friction at rest) is significantly higher than the dynamic friction (friction in motion). This causes jerky, unpredictable starts.

PTFE's consistent coefficient of friction virtually eliminates stick-slip, ensuring that movement is always smooth and predictable from the moment it begins.

Chemical and Environmental Inertness

PTFE is resistant to nearly all chemicals and is unaffected by moisture, UV radiation, or other environmental factors.

This chemical inertness guarantees that the bearing's material properties will not change over its lifespan, ensuring an indefinite operational life without fatigue or corrosion.

How Performance Stays Stable Across Conditions

The inherent properties of PTFE translate directly into consistent performance, even when operational conditions change.

Resilience to Load and Pressure

PTFE slide bearings are designed to operate effectively under high loads, with static capacities reaching up to 250 N/mm².

Crucially, the coefficient of friction remains stable even as the load changes, which is essential for structural applications where forces are dynamic.

Tolerance for Speed and Temperature

These bearings maintain their properties across a wide range of temperatures and can handle sliding speeds up to 2.5 m/s (dry).

This broad operational window makes them a versatile choice for applications from slow-moving bridge supports to industrial machinery.

Damping and Misalignment

The material has natural vibration-damping characteristics and can tolerate minor misalignments in a structure without compromising its function.

This forgiveness adds a layer of reliability in real-world installations where perfect alignment is not always possible.

Understanding the Trade-offs

To use PTFE bearings effectively, it's critical to understand their ideal operating conditions and limitations.

The High-Load, Low-Speed Sweet Spot

PTFE slide bearings perform best under conditions of high load and low speed.

It is in this environment that the material's self-lubricating and low-friction properties are most effective and provide the greatest advantage over other bearing types.

Not Ideal for High-Speed Dynamics

While tolerant of moderate speeds, these bearings are not the optimal choice for continuous, high-speed applications. Their primary strength lies in managing slow, heavy movements.

Installation Method Matters

Performance consistency relies on proper installation. Methods like bolting, welding, or mortar embedment must be executed correctly to ensure the load is transferred effectively to the bearing surface.

Making the Right Choice for Your Application

Use these guidelines to determine if a PTFE slide bearing is the correct solution for your goal.

- If your primary focus is structural integrity and long-term stability: PTFE bearings are an excellent choice due to their predictable friction under heavy loads and their maintenance-free, indefinite lifespan.

- If your primary focus is cost-efficiency and simple installation: The simple, compact design and versatile installation options make them a highly practical and economical solution for many projects.

- If your primary focus is a high-speed mechanical system: You should evaluate other bearing types specifically designed for high rotational or dynamic speeds, as this is outside PTFE's optimal performance range.

By understanding these core principles, you can confidently specify PTFE bearings for applications where unwavering reliability is paramount.

Summary Table:

| Key Property | Benefit for Performance |

|---|---|

| Low Coefficient of Friction (0.02-0.20) | Predictable, low resistance to movement |

| Self-Lubricating | Maintenance-free operation; no lubricant degradation |

| Eliminates Stick-Slip | Smooth, predictable motion from start |

| Chemical Inertness | Indefinite lifespan; resistant to corrosion and environmental factors |

| High Load Capacity (up to 250 N/mm²) | Stable performance under heavy, dynamic loads |

| Vibration Damping | Absorbs shocks and tolerates minor misalignments |

Need high-performance PTFE components that guarantee reliability?

At KINTEK, we specialize in manufacturing precision PTFE components—including seals, liners, labware, and custom parts—for the semiconductor, medical, laboratory, and industrial sectors. Our expertise ensures your PTFE slide bearings and other critical components are engineered for consistent, maintenance-free performance in your most demanding applications.

Contact KINTEB today to discuss your custom fabrication needs, from prototypes to high-volume orders.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments