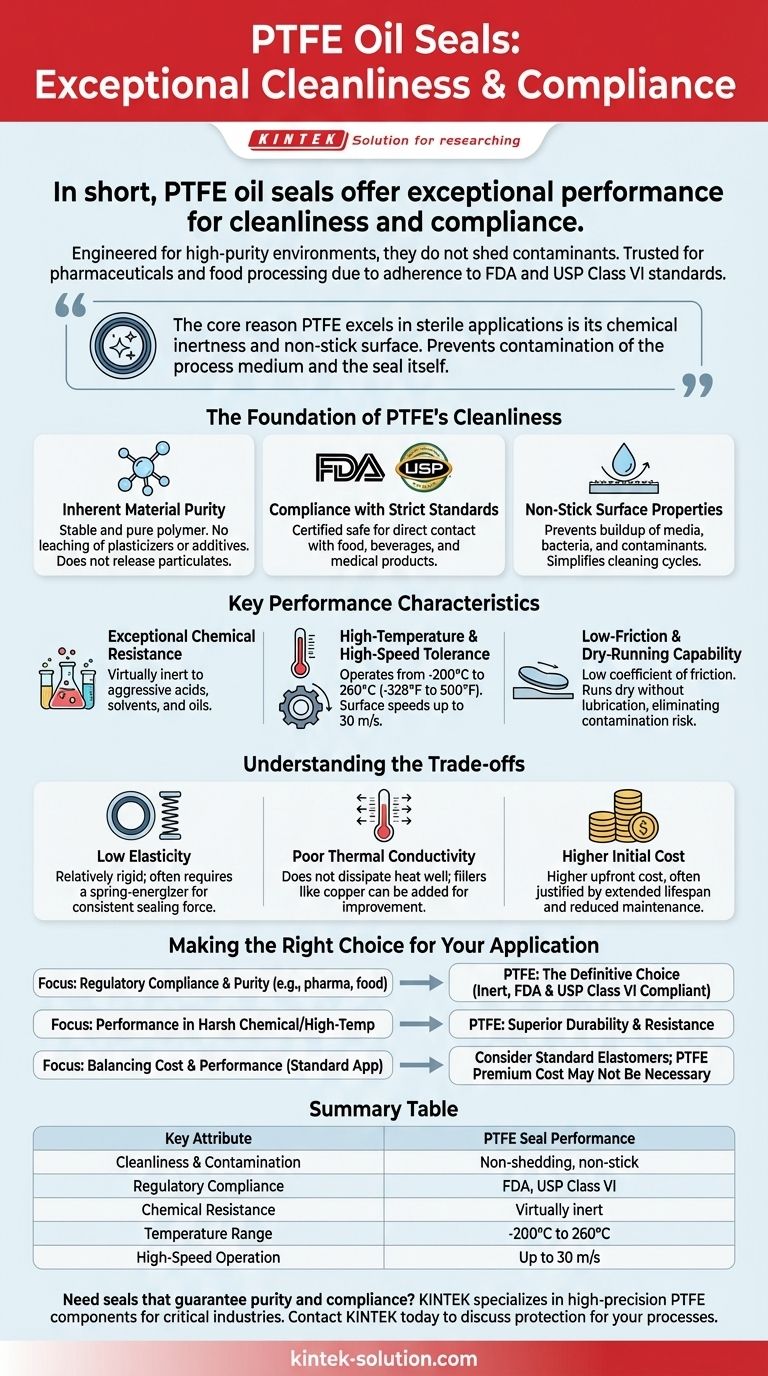

In short, PTFE oil seals offer exceptional performance for cleanliness and compliance. They are specifically engineered for high-purity environments because the material itself does not shed or precipitate contaminants. This inherent cleanliness, combined with compliance with stringent standards like FDA and USP Class VI, makes them a trusted choice for sensitive industries such as pharmaceuticals and food processing.

The core reason PTFE excels in sterile applications is its chemical inertness and non-stick surface. This combination prevents the seal from contaminating the process medium and stops process media from adhering to and corrupting the seal.

The Foundation of PTFE's Cleanliness

Polytetrafluoroethylene (PTFE) is not just a material; it's a strategic choice for applications where purity is non-negotiable. Its suitability stems from fundamental molecular properties that set it apart from traditional rubber or elastomer seals.

Inherent Material Purity

Unlike many sealing materials that can leach plasticizers or other additives over time, PTFE is an inherently stable and pure polymer. It does not break down or release particulates into the system, ensuring the integrity of the process fluid.

Compliance with Strict Standards

PTFE oil seals are manufactured to meet critical regulatory benchmarks. Their compliance with FDA (Food and Drug Administration) and USP Class VI (U.S. Pharmacopeia) standards certifies them as safe for direct contact with food, beverages, and medical products.

Non-Stick Surface Properties

The famous non-stick quality of PTFE is a significant advantage for cleanliness. This low-energy surface prevents process media, bacteria, and other contaminants from building up on the seal, simplifying cleaning cycles and reducing the risk of cross-contamination.

Key Performance Characteristics

While cleanliness is a primary driver, the overall performance profile of PTFE seals is what makes them so versatile and reliable in demanding conditions.

Exceptional Chemical Resistance

PTFE is virtually inert to most industrial chemicals, including aggressive acids, solvents, and oils. This ensures the seal maintains its structural integrity and sealing capability without degrading, even in the most corrosive environments.

High-Temperature and High-Speed Tolerance

These seals operate effectively across an extremely wide temperature range, typically from -200°C to 260°C (-328°F to 500°F). They are also engineered for high-speed rotating applications, often capable of handling surface speeds up to 30 m/s.

Low-Friction and Dry-Running Capability

The material's very low coefficient of friction minimizes wear and heat generation, extending service life and reducing energy consumption. Critically, this allows PTFE seals to run dry without lubrication, eliminating a potential source of contamination.

Understanding the Trade-offs

No material is perfect for every situation. Objectively evaluating PTFE requires understanding its limitations and how they are addressed in modern seal design.

Low Elasticity

PTFE is a relatively rigid material compared to rubber. To compensate for its low elasticity and ensure consistent sealing force, many PTFE seals incorporate a spring-energizer (often a stainless steel spring) into their design.

Poor Thermal Conductivity

In its pure form, PTFE does not dissipate heat well. For applications where heat buildup is a concern, fillers like copper or graphene can be added to the PTFE compound to improve its thermal conductivity.

Higher Initial Cost

PTFE oil seals typically have a higher upfront cost than standard elastomeric seals. However, this cost is often justified by their extended lifespan, reduced maintenance requirements, and the critical assurance of compliance in regulated industries.

Making the Right Choice for Your Application

Selecting the correct seal material is a critical engineering decision based on the specific demands of the environment.

- If your primary focus is regulatory compliance and purity (e.g., pharma, food processing): PTFE is the definitive choice due to its inert nature and adherence to FDA and USP Class VI standards.

- If your primary focus is performance in harsh chemical or high-temperature environments: PTFE's exceptional resistance makes it a superior and more durable option than most traditional elastomers.

- If your primary focus is balancing cost and performance in a standard application: The premium cost of PTFE may not be necessary if the extreme temperature, chemical, and cleanliness properties are not required.

Ultimately, choosing a PTFE oil seal is a strategic decision for applications where purity, long-term reliability, and compliance cannot be compromised.

Summary Table:

| Key Attribute | PTFE Seal Performance |

|---|---|

| Cleanliness & Contamination | Non-shedding, non-stick surface prevents media buildup and particle release. |

| Regulatory Compliance | Compliant with FDA and USP Class VI standards for food, beverage, and medical use. |

| Chemical Resistance | Virtually inert; resistant to aggressive acids, solvents, and oils. |

| Temperature Range | Performs from -200°C to 260°C (-328°F to 500°F). |

| High-Speed Operation | Capable of handling surface speeds up to 30 m/s. |

Need seals that guarantee purity and compliance?

KINTEK specializes in manufacturing high-precision PTFE components, including seals, liners, and labware, for industries where contamination is not an option. Our expertise in custom fabrication—from prototypes to high-volume orders—ensures you get a sealing solution that meets your exact specifications for performance and regulatory standards.

Contact KINTEK today to discuss how our PTFE seals can protect your critical processes.

Visual Guide

Related Products

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What makes PTFE stand out among materials used in sealing technology? Unmatched Chemical & Thermal Resistance

- What are the two temperature extremes discussed for PTFE seals? Maximize Performance from Cryogenic to High-Heat

- What are some common PTFE seal types used in industrial applications? Explore Solutions for Every Motion & Environment

- How do FEP and PTFE encapsulated O-rings contribute to equipment longevity? Prevent Costly Downtime with Superior Seals

- What is the overall operating temperature range for PTFE seals, gaskets, and O-rings? Achieve Sealing Integrity from -200°C to +260°C