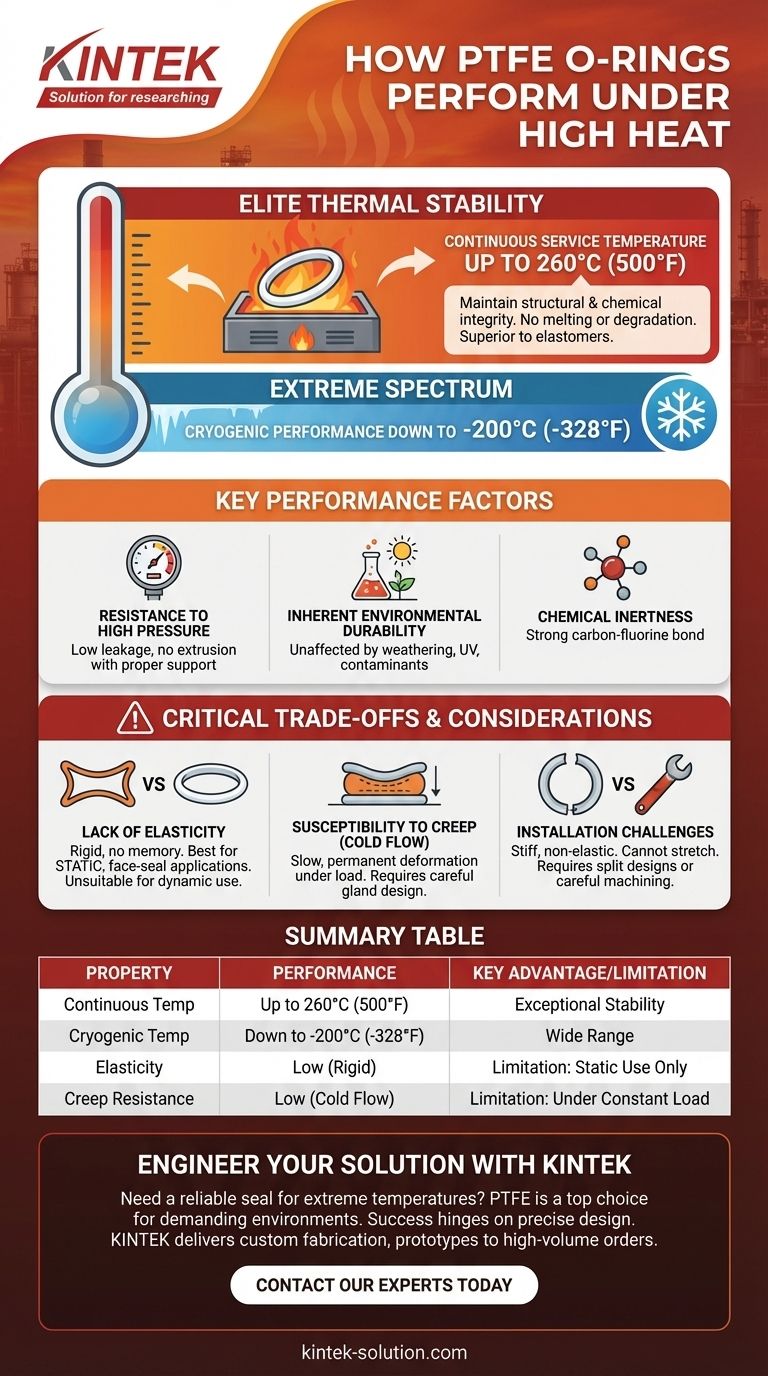

In short, Polytetrafluoroethylene (PTFE) O-Rings exhibit exceptional performance in high-heat conditions. They maintain their structural and chemical integrity without melting or degrading at continuous service temperatures up to 260°C (500°F), a point where many common elastomeric seals would fail catastrophically.

The core takeaway is that while PTFE offers elite thermal stability for sealing applications, its inherent rigidity and lack of memory create critical design trade-offs. Its suitability depends entirely on whether the application can accommodate the physical properties of a plastic rather than a traditional rubber.

How PTFE Achieves High-Temperature Performance

PTFE, commonly known by the brand name Teflon®, is not an elastomer (a rubber) but a fluoropolymer plastic. Its molecular structure, consisting of a strong carbon-fluorine bond, is responsible for its remarkable thermal stability and chemical inertness.

The Upper Service Temperature Limit

Standard PTFE O-Rings are rated for continuous service at temperatures as high as 260°C (500°F). Some specialized grades may even tolerate brief excursions to higher temperatures, such as the 316°C (600°F) noted for certain medical-grade materials.

Unlike many materials that soften and melt, PTFE remains functional and stable up to this limit, ensuring a reliable seal in demanding environments like pharmaceutical sterilization or high-temperature industrial processes.

Stability Across an Extreme Spectrum

PTFE's resilience is not limited to high heat. It also performs exceptionally well in cryogenic conditions, remaining functional at temperatures as low as -200°C (-328°F). This gives it one of the widest operating temperature ranges of any sealing material.

Key Performance Factors Beyond Temperature

While heat resistance is a primary feature, the overall performance of a PTFE seal depends on other interconnected factors.

Resistance to High Pressure

PTFE's robust nature allows it to withstand high-pressure conditions, especially when properly supported in a well-designed gland. It maintains its structural integrity without extruding, ensuring a low leakage rate even when high temperatures and pressures are combined.

Inherent Environmental Durability

PTFE is virtually immune to environmental degradation. It is unaffected by weathering, UV radiation, and exposure to contaminants. This ensures a long shelf life and reliable long-term performance in harsh operational settings.

Understanding the Critical Trade-offs

Choosing a material based on a single property can lead to design failure. While PTFE excels in temperature resistance, its plastic nature presents significant challenges compared to elastomeric O-rings.

The Challenge of Elasticity and Rebound

The most significant trade-off is PTFE's lack of elasticity. A traditional rubber O-ring compresses to create a seal and then rebounds when pressure is removed. PTFE O-rings are rigid and do not have this "memory."

This means they are best suited for static, face-seal applications where they are compressed and left in place. They are generally unsuitable for dynamic applications or situations requiring repeated compression and decompression.

Susceptibility to Creep (Cold Flow)

Under a constant compressive load, PTFE is subject to creep, also known as cold flow. This is a slow, permanent deformation of the material over time, which can eventually lead to a loss of sealing force and potential leakage. Careful gland design is critical to manage this effect.

Installation Considerations

Because they are stiff and non-elastic, PTFE O-rings cannot be stretched over components like their rubber counterparts. Installation often requires split designs or carefully machined grooves to avoid scratching or permanently deforming the ring, which would compromise the seal.

Making the Right Choice for Your Application

Selecting the correct seal requires balancing thermal needs with mechanical requirements.

- If your primary focus is extreme temperature and chemical resistance in a static application: PTFE is an outstanding choice, offering stability where other materials would simply disintegrate.

- If your application is dynamic or requires a resilient, compressive seal: A standard PTFE O-ring is likely inappropriate. You should instead investigate high-performance elastomers like FFKM or consider spring-energized PTFE seals, which use a metal spring to provide the necessary sealing force.

Ultimately, leveraging PTFE's thermal capabilities requires a clear understanding of its mechanical limitations.

Summary Table:

| Property | Performance |

|---|---|

| Continuous Service Temperature | Up to 260°C (500°F) |

| Cryogenic Performance | Down to -200°C (-328°F) |

| Key Advantage | Exceptional thermal stability & chemical inertness |

| Primary Limitation | Lack of elasticity; best for static, face-seal applications |

| Critical Consideration | Susceptible to creep (cold flow) under constant load |

Need a reliable seal for extreme temperatures?

PTFE's ability to perform continuously at 260°C (500°F) makes it a top choice for the most demanding environments in the semiconductor, medical, and industrial sectors. However, its success hinges on precise design to manage its unique properties, like creep and lack of elasticity.

At KINTEK, we don't just sell PTFE components—we deliver sealing solutions. Our expertise in custom fabrication ensures your O-rings, seals, liners, and labware are perfectly engineered for your specific high-temperature application, from prototypes to high-volume orders.

Let's engineer your solution together. Contact our experts today for a consultation.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability