At their core, PTFE lined check valves prevent backflow by using a mechanical barrier—such as a disc or plate—that allows fluid to flow in only one direction. The critical feature is the Polytetrafluoroethylene (PTFE) lining, which isolates the valve's internal components from corrosive or reactive fluids, ensuring the mechanism doesn't degrade, stick, or fail to create a perfect seal against reverse flow.

The function of a check valve is to stop backflow, but its integrity depends entirely on its ability to withstand its environment. A PTFE lining ensures this integrity by providing elite chemical resistance, transforming a standard valve into a durable, long-lasting solution for harsh industrial systems.

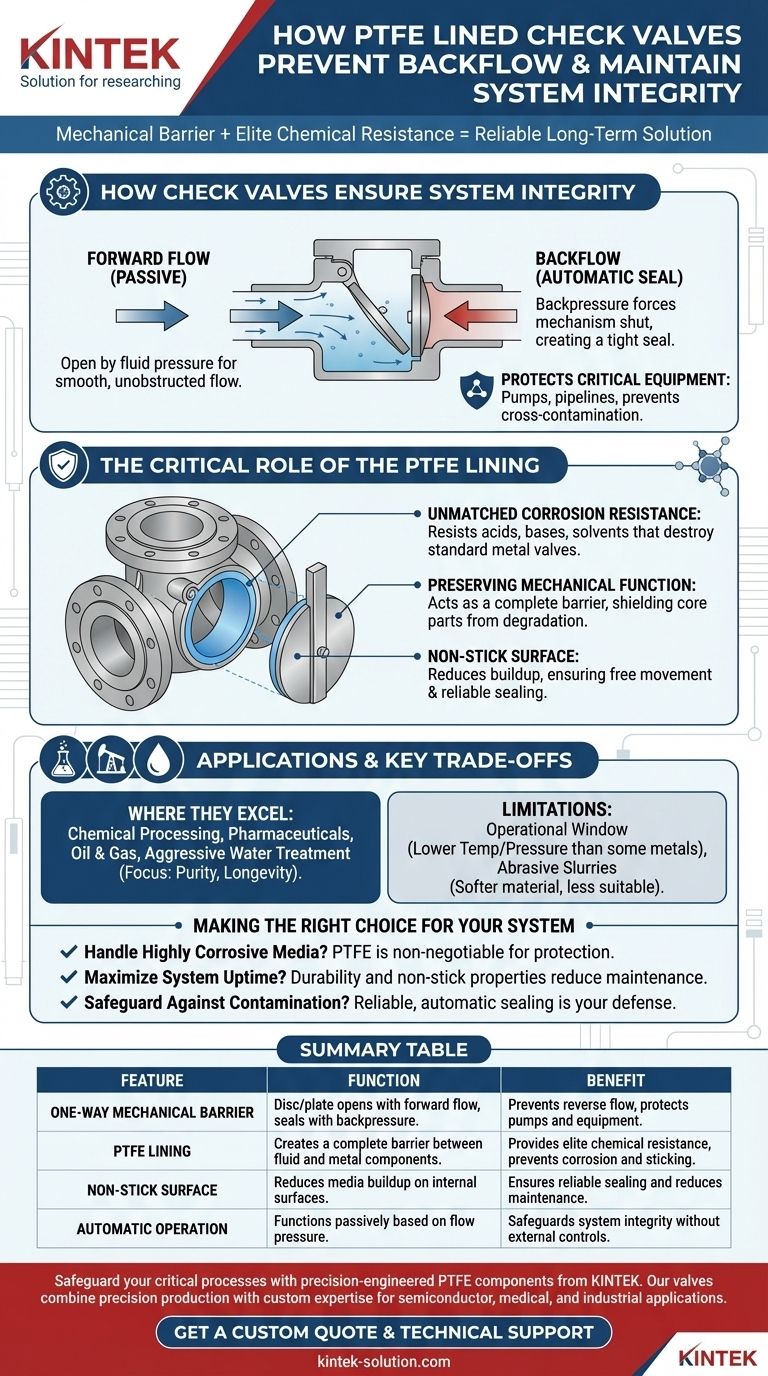

How Check Valves Ensure System Integrity

A check valve is fundamentally a one-way gate for fluids. Its operation is passive, relying on the pressure and direction of the flow itself rather than an external actuator.

The Principle of One-Way Flow

A check valve contains a mechanism, often a hinged disc or a set of spring-loaded plates, that is pushed open by the pressure of the fluid moving in the intended direction. This allows for smooth, unobstructed flow.

The Automatic Seal Against Backflow

When the forward flow stops or when pressure builds in the reverse direction (backpressure), this same mechanism is forced shut. The backpressure pushes the disc or plate against its seat, creating a tight seal that prevents any fluid from flowing backward.

Protecting Critical Equipment

This simple, automatic function is vital for protecting pumps, pipelines, and other sensitive equipment from the damaging effects of reverse flow and pressure surges. It also prevents cross-contamination between different parts of a system.

The Critical Role of the PTFE Lining

While the mechanical principle is straightforward, its long-term reliability is not guaranteed, especially when handling aggressive media. This is where the PTFE lining becomes the deciding factor.

Unmatched Corrosion Resistance

PTFE is one of the most chemically inert materials used in industry. It resists attack from a vast range of acids, bases, and solvents that would quickly corrode and destroy standard metal valves.

Preserving Mechanical Function

The PTFE lining acts as a complete barrier, shielding the valve's core metal structure and moving parts from the fluid. This prevents the degradation that could cause the valve's disc to seize, warp, or fail to seal properly against its seat.

Non-Stick Surface for Uninterrupted Operation

PTFE is famous for its non-stick properties. This characteristic reduces the buildup of deposits or crystallized media on the valve's internal surfaces, ensuring the mechanism can move freely and close completely every time.

Applications and Key Trade-offs

The unique combination of mechanical backflow prevention and superior chemical resistance makes these valves essential in demanding industries but also introduces specific limitations.

Where PTFE Lined Valves Excel

These valves are the standard choice in sectors where fluid purity and equipment longevity are paramount. This includes chemical processing, pharmaceutical manufacturing, oil and gas production, and aggressive water treatment applications.

A Note on Valve Design

While the principle is the same, you will often encounter specific designs like the dual plate check valve. This design uses two spring-loaded, semi-circular plates, offering a compact, lightweight, and efficient solution that is easy to install.

Understanding the Limitations

The primary trade-off with PTFE is its operational window. It has temperature and pressure limitations that are lower than many metals. It is also a softer material, making it less suitable for applications involving highly abrasive slurries that could physically wear away the lining over time.

Making the Right Choice for Your System

Selecting the correct valve is about matching its capabilities to your primary operational goal.

- If your primary focus is handling highly corrosive media: The PTFE lining is non-negotiable for protecting the valve's internal mechanism and ensuring a reliable seal over the long term.

- If your primary focus is maximizing system uptime: The durability and non-stick properties of PTFE significantly reduce maintenance cycles and premature failures caused by chemical attack or media buildup.

- If your primary focus is safeguarding against contamination: The valve's reliable, automatic sealing action is your first line of defense in preventing backward flow that could compromise fluid purity.

Ultimately, choosing a PTFE lined check valve is an investment in the stability and longevity of your entire fluid handling system.

Summary Table:

| Feature | Function | Benefit |

|---|---|---|

| One-Way Mechanical Barrier | Disc/plate opens with forward flow, seals with backpressure. | Prevents reverse flow, protects pumps and equipment. |

| PTFE Lining | Creates a complete barrier between fluid and metal components. | Provides elite chemical resistance, prevents corrosion and sticking. |

| Non-Stick Surface | Reduces media buildup on internal surfaces. | Ensures reliable sealing and reduces maintenance. |

| Automatic Operation | Functions passively based on flow pressure. | Safeguards system integrity without external controls. |

Safeguard your critical processes with precision-engineered PTFE components from KINTEK.

Our PTFE lined check valves are designed for maximum reliability in the most demanding semiconductor, medical, laboratory, and industrial applications. We combine precision production with extensive custom fabrication expertise—from initial prototypes to high-volume production—to deliver a solution that perfectly matches your system's requirements for chemical resistance, purity, and uptime.

Contact us today to discuss your specific needs and let our experts help you enhance your system's integrity and longevity.

Get a Custom Quote & Technical Support

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What design considerations are important for custom PTFE parts? Design for Performance & Reliability

- What industrial benefits do PTFE-machined parts offer? Achieve Peak Performance in Demanding Applications

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What are the unique properties of PTFE? The 3 Pillars Driving Demand for High-Performance Parts

- What are the main applications of PTFE type Teflon? Unlock Its Versatility for Your Industry