In the automotive industry, PTFE guide strips are critical components that directly enhance vehicle performance, reliability, and efficiency. They are primarily used in engine components, braking systems, and suspension systems to reduce friction, withstand extreme operating conditions, and ensure smooth, reliable movement between parts.

The core benefit of PTFE is not a single characteristic, but its unique combination of properties. It provides an exceptionally low-friction surface that remains stable and durable even when exposed to the high temperatures and corrosive chemicals common in modern vehicles.

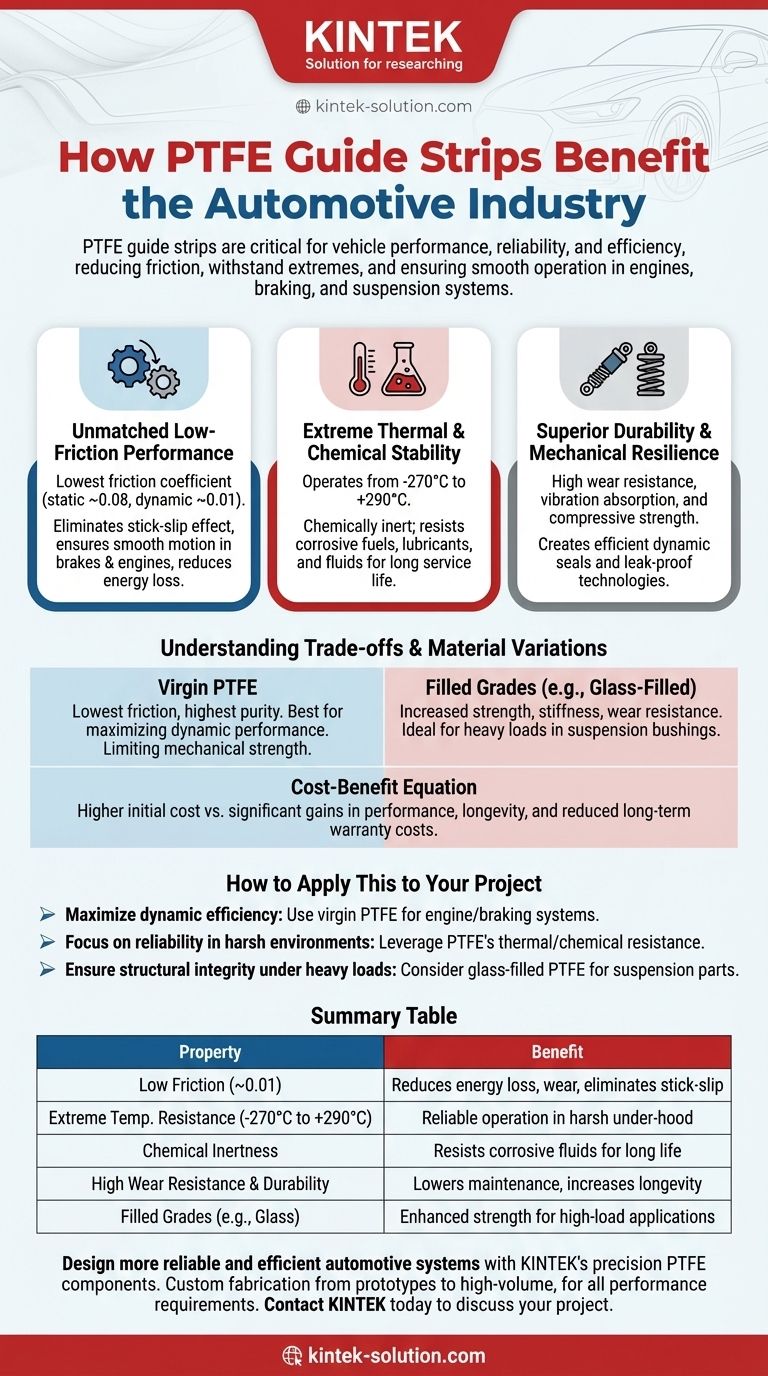

The Core Properties Driving Automotive Adoption

To understand the value of PTFE, we must look at the fundamental material properties that solve key engineering challenges in the automotive world.

Unmatched Low-Friction Performance

PTFE possesses one of the lowest coefficients of friction of any solid material, with a static coefficient around 0.08 and a dynamic coefficient as low as 0.01.

This near-frictionless surface minimizes energy loss, reduces component wear, and crucially, eliminates the "stick-slip" effect. This ensures perfectly smooth and predictable motion, which is vital for the precise operation of braking and engine systems.

Extreme Thermal and Chemical Stability

Automotive environments are incredibly harsh. PTFE guide strips excel here due to their ability to operate across a vast temperature range, from -270°C to +290°C.

Furthermore, PTFE is almost completely chemically inert. It is resistant to corrosive automotive fluids, including fuels, lubricants, brake fluid, and coolants, ensuring components have a long and reliable service life without degradation.

Superior Durability and Mechanical Resilience

Beyond its stability, PTFE provides excellent mechanical benefits. It offers high wear resistance, good vibration absorption, and high resistance to compressive forces.

These properties contribute to more efficient dynamic seals and create leak-proof technologies that prevent fluid loss. This inherent toughness translates directly into longer-lasting parts and reduced maintenance requirements.

Understanding the Trade-offs and Material Variations

While PTFE is a superior material, its application requires an understanding of its different forms and limitations. Not all PTFE is the same, and choosing the correct grade is essential for optimal performance.

Base PTFE vs. Filled Grades

Virgin PTFE offers the lowest friction and highest chemical purity. However, for applications involving heavy loads, its mechanical strength can be a limiting factor.

To overcome this, filled PTFE grades are used. For example, glass-filled PTFE is common in suspension components like bushings and thrust washers. The glass fibers significantly increase mechanical strength, stiffness, and wear resistance, making it suitable for high-load dynamic conditions.

The Cost-Benefit Equation

PTFE is one of the most affordable fluoropolymers, but it is more expensive than many commodity plastics. Its use is therefore a deliberate engineering choice.

The higher initial cost is justified by significant gains in performance, a dramatic increase in component service life, and enhanced vehicle reliability, which can lower long-term warranty and maintenance costs.

How to Apply This to Your Project

Your choice of material should be dictated by your primary engineering goal.

- If your primary focus is maximizing dynamic performance and efficiency: Use virgin PTFE guide strips to eliminate stick-slip effects and reduce energy loss in systems like engine components or advanced braking systems.

- If your primary focus is reliability and longevity in harsh environments: Leverage PTFE's unmatched thermal and chemical resistance to protect components from corrosive fuels, oils, and high temperatures.

- If your primary focus is structural integrity under heavy dynamic loads: Consider glass-filled PTFE for components like suspension bushings, where superior mechanical strength and wear resistance are paramount.

Understanding these material properties empowers you to design more robust, efficient, and reliable automotive systems.

Summary Table:

| Property | Benefit for Automotive Industry |

|---|---|

| Low Friction (Coefficient ~0.01) | Reduces energy loss, wear, and eliminates stick-slip in brakes/engines |

| Extreme Temperature Resistance (-270°C to +290°C) | Ensures reliable operation in harsh under-hood environments |

| Chemical Inertness | Resists corrosive fuels, oils, and brake fluids for long service life |

| High Wear Resistance & Durability | Lowers maintenance needs and increases component longevity |

| Filled Grades (e.g., Glass) | Provides enhanced strength for high-load applications like suspension bushings |

Design more reliable and efficient automotive systems with KINTEK's precision PTFE components.

Whether you need to eliminate stick-slip in braking systems, protect engine components from extreme heat, or enhance the durability of suspension parts under heavy loads, KINTEK has the expertise and manufacturing capability to support your project. We specialize in custom fabrication of high-performance PTFE seals, liners, guide strips, and labware for the semiconductor, medical, laboratory, and industrial sectors—including automotive applications.

We prioritize precision production and offer custom solutions from prototypes to high-volume orders, ensuring you get the right PTFE grade (virgin or filled) for your specific performance requirements.

Contact KINTEK today to discuss how our PTFE components can improve your vehicle's performance, reliability, and longevity.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Customizable PTFE Rods for Advanced Industrial Applications

People Also Ask

- What toolpath strategies benefit thin-wall PTFE machining? Master Precision with Helical Paths and Low-Stress Techniques

- What are the uses of Polytetrafluoroethylene (PTFE) with a Proprietary Fill? Enhance Performance for Demanding Applications

- Are there reasons to still use traditional O-rings? Yes, for proven reliability and global availability.

- How do fillers enhance PTFE's properties? Unlock Superior Wear Resistance & Stability

- What is the primary function of PTFE expansion bellows? Solve Movement and Corrosion Challenges

- Why is PTFE an excellent material for coating machine parts? Achieve Superior Performance & Durability

- What are the advantages of PTFE gaskets? Superior Sealing for Extreme Chemical & Thermal Environments

- What temperature range can PTFE gaskets withstand in ball valve applications? From -200°C to 260°C