The short answer is its profound chemical inertness and physical impermeability. Polytetrafluoroethylene (PTFE) possesses a unique molecular structure that makes it virtually immune to chemical attack. This inherent non-reactivity, combined with a dense, non-porous physical form, creates a formidable barrier that prevents corrosive fluids, gases, and vapors from ever reaching the critical sealing surfaces.

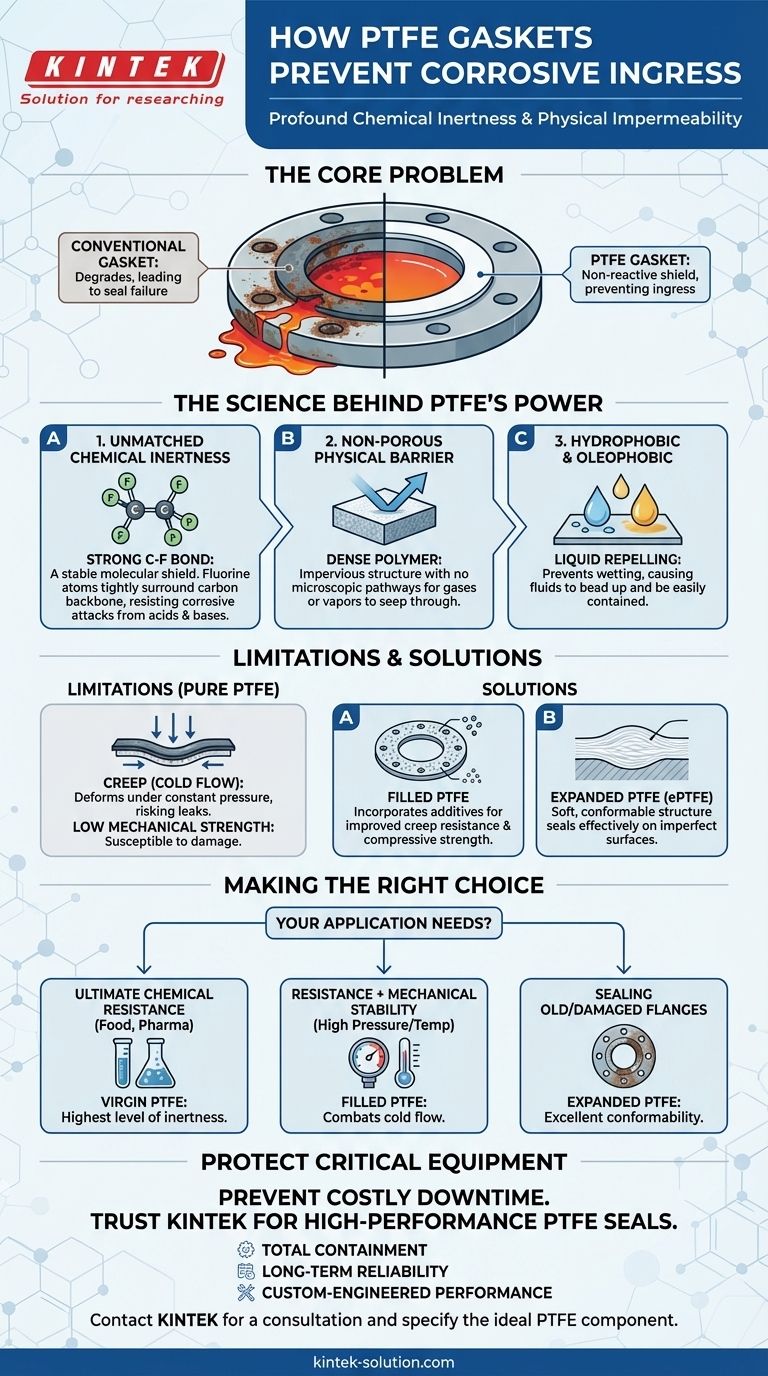

The core problem is that most gasket materials degrade when exposed to harsh chemicals, eventually causing seal failure. PTFE solves this by being fundamentally non-reactive; it creates an impenetrable shield not through resistance, but through chemical indifference.

The Science Behind PTFE's Sealing Power

To understand how PTFE protects a seal, we must look at its two primary properties: its chemical makeup and its physical structure. These two factors work in concert to create a nearly perfect sealing material for corrosive environments.

Unmatched Chemical Inertness

The key to PTFE's performance is the carbon-fluorine bond, one of the strongest single bonds in organic chemistry. This bond creates a molecule that is incredibly stable and non-reactive.

Think of it as a molecular shield. The fluorine atoms tightly surround the carbon backbone, leaving no weak points for corrosive chemicals—from aggressive acids to alkaline solutions—to attack. The material simply does not participate in chemical reactions.

A Non-Porous Physical Barrier

Beyond its chemical nature, PTFE is a dense polymer with extremely low porosity. This solid structure is impervious to gases and vapors, meaning there are no microscopic pathways for corrosive fluids to seep through the gasket material itself.

This effectively blocks the primary method of ingress, ensuring the fluid is contained and the flange surfaces are protected.

Hydrophobic and Oleophobic Nature

PTFE is also intensely water-repelling (hydrophobic) and oil-repelling (oleophobic), a property famous from its use in non-stick cookware.

This characteristic prevents corrosive liquids from "wetting" the gasket's surface. Instead of spreading out and potentially finding a microscopic path, the fluid beads up and is easily contained, further enhancing the seal's integrity.

Understanding the Limitations and Considerations

While PTFE is a superior material for chemical resistance, it is not a universal solution. An objective assessment requires understanding its mechanical trade-offs, particularly in its pure, or "virgin," form.

Tendency to Creep (Cold Flow)

The most significant limitation of virgin PTFE is creep, also known as cold flow. This is the tendency for the material to slowly deform over time when under constant pressure (i.e., the compressive load from flange bolts).

In high-pressure or high-temperature applications, this can lead to a loss of bolt torque and a potential leak path.

Mechanical Strength

Compared to metallic or other filled gasket types, pure PTFE is a relatively soft material. It can be susceptible to damage during installation if flanges are misaligned or if excessive and uneven bolt torque is applied.

Solutions: Filled and Expanded PTFE

Engineers have solved these mechanical limitations by creating composite materials. Filled PTFE gaskets incorporate substances like glass, carbon, or silica to drastically improve creep resistance and compressive strength.

Expanded PTFE (ePTFE) modifies the material's structure to create a soft, highly conformable gasket that resists creep and seals effectively even on irregular flange surfaces.

Making the Right Choice for Your Application

Selecting the correct PTFE gasket requires matching the material's properties to the specific demands of your operating environment.

- If your primary focus is ultimate chemical resistance: Virgin PTFE provides the highest level of inertness for the most aggressive acids, solvents, and bases, especially in food or pharmaceutical applications.

- If you need chemical resistance plus mechanical stability: A filled PTFE gasket is the superior choice for handling higher pressures and temperatures without the risk of cold flow.

- If you are sealing old or damaged flanges: Expanded PTFE (ePTFE) offers excellent chemical resistance combined with the soft conformability needed to create a reliable seal on imperfect surfaces.

By understanding these core principles, you can confidently specify a gasket that provides an impenetrable defense for your critical equipment.

Summary Table:

| Property | How It Prevents Ingress | Key Consideration |

|---|---|---|

| Chemical Inertness | Non-reactive C-F bonds resist all acids, bases, and solvents. | Pure PTFE offers the highest chemical resistance. |

| Physical Impermeability | Dense, non-porous structure blocks fluid and vapor seepage. | Provides a solid barrier with no microscopic pathways. |

| Hydrophobic/Oleophobic | Repels liquids, preventing them from wetting the surface. | Enhances containment by causing fluids to bead up. |

| Mechanical Strength | Pure PTFE is soft; filled or expanded grades improve stability. | Filled/ePTFE versions resist creep and handle higher pressures. |

Protect Your Critical Equipment with Precision-Engineered PTFE Seals

Does your application demand a reliable seal against aggressive chemicals? The right PTFE gasket is crucial for preventing costly downtime and equipment failure.

KINTEK manufactures high-performance PTFE components—including seals, gaskets, liners, and custom labware—for the semiconductor, medical, laboratory, and industrial sectors. We combine precision production with custom fabrication expertise, from initial prototypes to high-volume orders, ensuring your gaskets deliver optimal chemical resistance and mechanical integrity.

Let us provide a sealing solution that guarantees:

- Total Containment: Leverage PTFE's profound inertness to safely handle your most corrosive fluids.

- Long-Term Reliability: Benefit from filled or expanded PTFE options that combat cold flow in demanding applications.

- Custom-Engineered Performance: Get a gasket perfectly tailored to your specific pressure, temperature, and flange conditions.

Ready to solve your toughest sealing challenges? Contact KINTEK today for a consultation and let our experts help you specify the ideal PTFE component for your needs.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

People Also Ask

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech