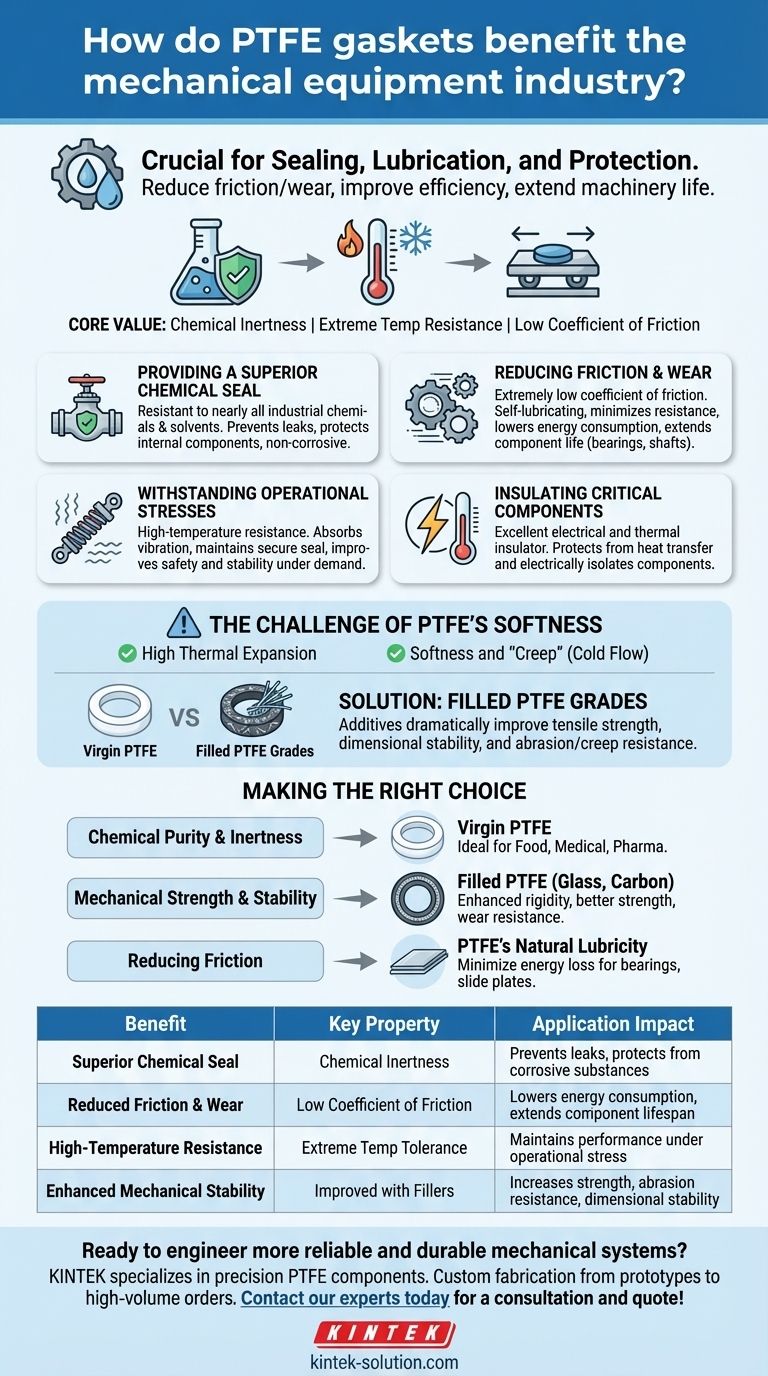

In the mechanical equipment industry, PTFE gaskets are crucial components that provide superior sealing, lubrication, and protection. They are used on everything from fastening bolts and nuts to complex bearing assemblies, where they significantly reduce friction and wear, improve operational efficiency, and extend the service life of the machinery.

The core value of PTFE in mechanical applications lies in its unique combination of chemical inertness, extreme temperature resistance, and an exceptionally low coefficient of friction. This makes it an essential material for enhancing equipment reliability and longevity, provided its inherent softness is managed correctly.

The Core Functions of PTFE in Mechanical Systems

Polytetrafluoroethylene (PTFE) is not just a simple sealing material; it performs several critical functions that protect and enhance the performance of mechanical equipment.

Providing a Superior Chemical Seal

PTFE is almost universally inert, meaning it is resistant to nearly all industrial chemicals and solvents. This makes it an ideal sealing material to prevent leaks and protect internal components from corrosive substances.

This non-corrosive property ensures the gasket itself does not degrade or become a source of contamination within the system.

Reducing Friction and Wear

One of PTFE’s most valuable properties is its extremely low coefficient of friction—one of the lowest of any solid material. This allows moving parts to operate with minimal resistance.

This self-lubricating nature is critical in applications where external lubricants are undesirable, such as in food or pharmaceutical processing, or in assemblies that are difficult to access for regular maintenance.

By minimizing friction, PTFE gaskets directly reduce mechanical wear, lower energy consumption, and extend the lifespan of components like bearings and shafts.

Withstanding Operational Stresses

Mechanical equipment is subject to constant stress from temperature fluctuations and vibration. PTFE gaskets excel in these environments due to their high-temperature resistance.

Their ability to absorb vibration helps maintain a secure and reliable seal, improving the overall safety and stability of the equipment under demanding operational conditions.

Insulating Critical Components

PTFE is an excellent electrical and thermal insulator. This property is valuable in applications where mechanical components must be electrically isolated or protected from heat transfer.

Understanding the Trade-offs: The Challenge of PTFE's Softness

While its properties are highly beneficial, it is critical to understand the primary limitation of virgin PTFE: its relative softness and dimensional instability.

High Thermal Expansion

As a mechanical component, PTFE is sensitive to temperature changes and exhibits high thermal expansion. This means its dimensions can change significantly with temperature, which must be accounted for during design.

Softness and "Creep"

Under sustained pressure, virgin PTFE can be prone to "creep" or cold flow, where the material slowly deforms. This can compromise seal integrity in high-load applications if not properly managed.

The Solution: Filled PTFE Grades

To overcome these mechanical limitations, PTFE is often blended with fillers. Additives like glass fibers, carbon, or graphite dramatically improve its properties.

These filled PTFE grades offer increased tensile strength, better dimensional stability, and significantly higher resistance to abrasion and creep, making them suitable for more demanding mechanical roles.

Making the Right Choice for Your Application

Selecting the correct type of PTFE is essential for maximizing equipment performance and reliability.

- If your primary focus is chemical purity and inertness: Virgin PTFE is the ideal choice, especially in food, medical, or pharmaceutical applications where contamination is not an option.

- If your primary focus is mechanical strength and stability: Choose a filled PTFE gasket. Glass-filled variants offer enhanced rigidity, while carbon-filled options provide better strength and wear resistance.

- If your primary focus is reducing friction in moving parts: PTFE's natural lubricity is a key advantage for bearings, slide plates, and other components where minimizing energy loss and wear is critical.

Ultimately, understanding both the exceptional benefits and the specific limitations of PTFE allows you to engineer more efficient, reliable, and durable mechanical systems.

Summary Table:

| Benefit | Key Property | Application Impact |

|---|---|---|

| Superior Chemical Seal | Chemical Inertness | Prevents leaks and protects against corrosive substances. |

| Reduced Friction & Wear | Low Coefficient of Friction | Lowers energy consumption and extends component lifespan. |

| High-Temperature Resistance | Extreme Temperature Tolerance | Maintains performance under operational stress and fluctuations. |

| Enhanced Mechanical Stability | Improved with Fillers (Glass, Carbon) | Increases strength, abrasion resistance, and dimensional stability. |

Ready to engineer more reliable and durable mechanical systems?

At KINTEK, we specialize in the precision manufacturing of high-performance PTFE components, including seals, gaskets, liners, and custom labware. Whether your application demands the chemical purity of virgin PTFE for semiconductor or medical industries, or the enhanced mechanical strength of filled PTFE for heavy industrial equipment, we provide custom fabrication from prototypes to high-volume orders.

Let us help you select the perfect PTFE solution to reduce downtime, lower maintenance costs, and extend the life of your machinery.

Contact our experts today for a consultation and quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability