PTFE extruded rods provide exceptional electrical insulation due to a powerful combination of inherent material properties. They possess extremely high electrical resistance and superb dielectric strength, allowing them to withstand high voltages without leakage, while also demonstrating remarkable stability across a wide range of temperatures and harsh chemical environments.

The true value of PTFE for electrical insulation isn't just its ability to block current, but its unwavering reliability in environments with extreme temperatures, corrosive chemicals, and mechanical stress, making it a definitive choice for mission-critical applications.

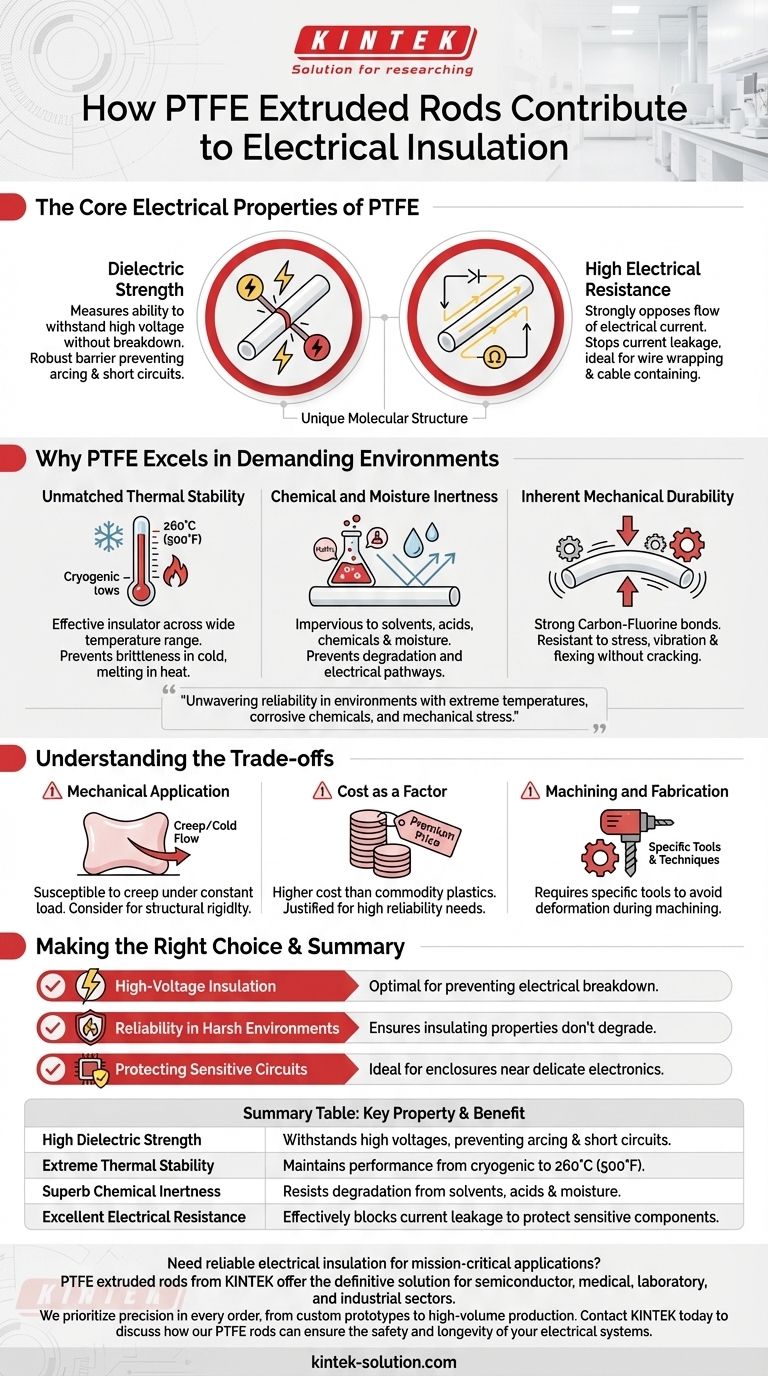

The Core Electrical Properties of PTFE

Polytetrafluoroethylene (PTFE) is not merely a good insulator; it is one of the best available. Its performance stems from its unique molecular structure, which results in two primary electrical characteristics.

Unpacking Dielectric Strength

Dielectric strength is a measure of a material's ability to withstand high voltage before it breaks down and begins to conduct electricity.

PTFE has a superb dielectric strength, meaning it can serve as a robust barrier between electrical conductors even when very high voltages are applied. This prevents arcing and short circuits, which is critical for protecting sensitive electronics and ensuring safety.

High Electrical Resistance

Electrical resistance refers to how strongly a material opposes the flow of electrical current.

PTFE is an excellent insulator because it has extremely high electrical resistance. It effectively stops current from leaking or traveling where it shouldn't, making it ideal for wrapping wires, cables, and connectors to contain the electrical energy.

Why PTFE Excels in Demanding Environments

While its core electrical properties are impressive, PTFE's true advantage lies in its ability to maintain those properties under conditions that would cause lesser materials to fail.

Unmatched Thermal Stability

PTFE remains an effective insulator across an exceptionally wide temperature range, from cryogenic lows up to 260°C (500°F).

Other plastics can become brittle and crack in the cold or melt at high temperatures, compromising their insulating capabilities. PTFE's thermal stability ensures consistent, reliable performance in engines, industrial equipment, and aerospace applications.

Chemical and Moisture Inertness

PTFE is famously impervious to nearly all solvents, acids, and chemicals. It also does not absorb moisture.

This chemical inertness prevents the material from degrading over time. Moisture and chemical exposure can create pathways for electrical current in other materials, but PTFE rods maintain their integrity, protecting components from corrosion and electrical damage.

Inherent Mechanical Durability

The strong carbon-fluorine bonds in PTFE's structure give it a unique flexibility and resistance to stress.

This ensures the insulation remains intact even when subjected to vibration or minor physical flexing. It won't easily crack or wear away, providing long-lasting protection for the electrical components it encases.

Understanding the Trade-offs

While PTFE is a superior electrical insulator, it is essential to understand its specific characteristics to apply it correctly. No material is perfect for every situation.

Considerations for Mechanical Application

PTFE is a relatively soft material. It can be susceptible to "creep" or cold flow, meaning it can deform over time when under a constant compressive load. For structural applications requiring high rigidity, other materials may be more suitable.

Cost as a Factor

As a high-performance polymer, PTFE is generally more expensive than commodity plastics like PVC or polyethylene. Its use is typically justified by the need for high reliability in demanding electrical or environmental conditions where failure is not an option.

Machining and Fabrication

While PTFE is easily machined, its softness and thermal properties require specific tools and techniques to achieve tight tolerances without causing the material to deform or gum up cutting tools.

Making the Right Choice for Your Application

Selecting PTFE is a decision for uncompromising performance. Evaluate your project's primary goal to confirm it is the optimal choice.

- If your primary focus is high-voltage insulation: PTFE's exceptional dielectric strength makes it one of the most reliable choices to prevent electrical breakdown and arcing.

- If your primary focus is reliability in harsh environments: PTFE's thermal and chemical stability ensures its insulating properties will not degrade from heat, corrosive agents, or moisture.

- If your primary focus is protecting sensitive circuits: PTFE's ability to prevent electrical leakage and interference makes it ideal for enclosures and components near delicate electronics.

Ultimately, specifying PTFE extruded rods is a decision for uncompromising electrical insulation and long-term component safety.

Summary Table:

| Key Property | Benefit for Electrical Insulation |

|---|---|

| High Dielectric Strength | Withstands high voltages, preventing arcing and short circuits. |

| Extreme Thermal Stability | Maintains performance from cryogenic temperatures up to 260°C (500°F). |

| Superb Chemical Inertness | Resists degradation from solvents, acids, and moisture, ensuring long-term reliability. |

| Excellent Electrical Resistance | Effectively blocks current leakage to protect sensitive components. |

Need reliable electrical insulation for mission-critical applications?

PTFE extruded rods from KINTEK offer the definitive solution for industries where failure is not an option. Our components provide the exceptional dielectric strength, thermal stability, and chemical resistance required in the semiconductor, medical, laboratory, and industrial sectors.

We prioritize precision in every order, from custom prototypes to high-volume production.

Contact KINTEK today to discuss how our PTFE rods can ensure the safety and longevity of your electrical systems.

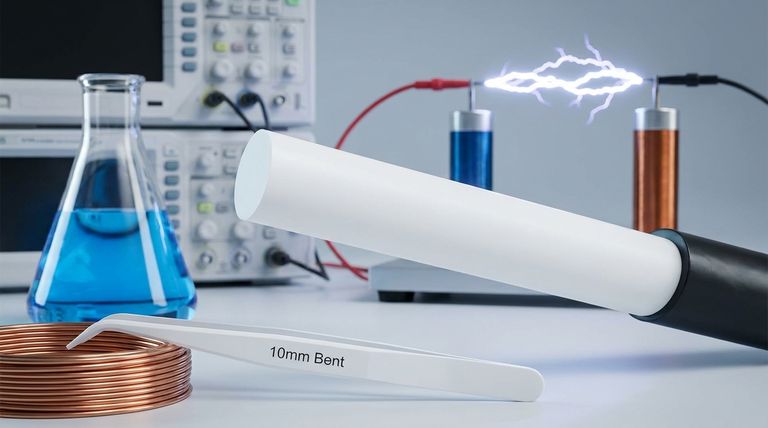

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers